Abstract

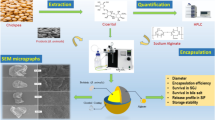

Longevity of probiotic is the main concern for getting maximum benefits when added in food product. Bifidobacterium, a probiotic, tends to lose its viability during gastrointestinal track (GIT) transit and storage of food. Their viability can be enhanced through microencapsulation technology. In this study, Bifidobacterium bifidum (B. bifidum) ATCC 35914 was encapsulated by using two experimental plans. In the first plan, chitosan (CH) at 0.6, 0.8, and 1.0% and sodium alginate (SA) at 4, 5, and 6% were used. Based on encapsulation efficiency, 6% sodium alginate and 0.8% chitosan were selected for single coating of the bacteria, and the resulting micro beads were double coated with different concentrations (5, 7.5, and 10%) of whey protein concentrate (WPC) in the second plan. Encapsulation efficiency and GIT tolerance were determined by incubating the micro beads in simulated gastrointestinal juices (SIJ) at variable pH and exposure times, and their release (liberation of bacterial cells) profile was also observed in SIJ. The microencapsulated bacterial cells showed significantly (P < 0.01) higher viability as compared to the unencapsulated (free) cells during GIT assay. The double-coated micro beads SA 6%–WPC 5% and CH 0.8%–WPC 5% were proven to have the higher survival at pH 3.0 after 90 min of incubation time and at pH 7.0 after 3-h exposure in comparison to free cells in simulated conditions of the stomach and intestine, respectively. Moreover, double coating with whey protein concentrate played a significant role in the targeted (106–9 CFU/mL) delivery under simulated intestinal conditions.

Similar content being viewed by others

References

Deshpande KG, Dolas CB, Chavan NS (2014) Investigation of tolerance of Lactobacillus casei to the presence of acids, bile salts and deconjugation of bile salts. Int J Curr Microbiol App Sci 3:600–612

Shah D (2007) Functional cultures and health benefits. Int Dairy J 17(11):1262–1277. https://doi.org/10.1016/j.idairyj.2007.01.014

Vieira AT, Rocha VM, Tavares L, Garcia CC, Teixeira MM, Oliveira SC, Cassali GD, Gamba C, Martins FS, Nicoli JR (2016) Control of Klebsiella pneumoniae pulmonary infection and immunomodulation by oral treatment with the commensal probiotic Bifidobacterium longum. Microb Infect 18(3):180–189. https://doi.org/10.1016/j.micinf.2015.10.008

De Freitas Fonseca J (2015) Effect of Bifidobacterium longum on the Weissella paramesenteroides WpK4 328 em giardíase experimental. Available at: http://www.bibliotecadigital.ufmg.br/dspace/handle/1843/BUBD-9WEVXW

Eckert C, Serpa VG, dos Santos ACF, da Costa SM, Dalpubel V, Lehn DN, de Souza CFV (2017) Microencapsulation of Lactobacillus plantarum ATCC 8014 through spray drying and using dairy whey as wall materials. LWT-Food Sci Technol 82:176–183. https://doi.org/10.1016/j.lwt.2017.04.045

Bernucci BS, Loures CM, Lopes SC, Oliveira MC, Sabino AP, Vilela JM, Andrade MS, Lacerda IC, Nicoli JR, Oliveira ES (2017) Effect of microencapsulation conditions on the viability and functionality of Bifidobacterium longum. LWT-Food Sci Technol 80:341–347. https://doi.org/10.1016/j.lwt.2017.02.036

Holkem AT, Raddatz GC, Barin JS, Flores EMM, Muller EI, Codevilla CF, Jacob-Lopes E, Grosso CRF, de Menezes CR (2017) Production of microcapsules containing Bifidobacterium BB-12 by emulsification/internal gelation. LWT-Food Sci Technol 76:216–221. https://doi.org/10.1016/j.lwt.2016.07.013

Carvalho AS, Silva J, Ho P, Teixeira P, Malcata FX, Gibbs P (2004) Relevant factors for the preparation of freeze-dried lactic acid bacteria. Int Dairy J 14(10):835–847. https://doi.org/10.1016/j.idairyj.2004.02.001

Sabikhi D (2010) Enhanced survival of probiotic Lactobacillus aciduphillus by encapsulation with the nano structured polyelectrolyte layers through layer-by-layer approach. J Agri Food Chem 59:11838–11845

Prasanna PH, Grandison AS, Charalampopoulos D (2014) Bifidobacteria in milk products: an overview of physiological and biochemical properties, exopolysaccharide production, selection criteria of milk products and health benefits. Food Res Int 55:247–262. https://doi.org/10.1016/j.foodres.2013.11.013

Coghetto CC, Vasconcelos CB, Brinques GB, Ayub MA (2016) Lactobacillus plantarum BL011 cultivation in industrial isolated soybean protein acid residue. Braz J Microbiol 47(4):941–948. https://doi.org/10.1016/j.bjm.2016.06.003

Tripathi MK, Giri SK (2014) Probiotic functional foods: survival of probiotics during processing and storage. J Funct Foods 9:225–241. https://doi.org/10.1016/j.jff.2014.04.030

Darjani P, Nezhad MH, Kadkhodaee R, Milani E (2016) Influence of prebiotic and coating materials on morphology and survival of a probiotic strain of Lactobacillus casei exposed to simulated gastrointestinal conditions. LWT-Food Sci Technol 73:162–167. https://doi.org/10.1016/j.lwt.2016.05.032

Pan LX, Fang XJ, Yu Z, Xin Y, Liu XY, Shi LE (2013) Encapsulation in alginate-skim microspheres improves viability of Lactobacillus bulgaricus in stimulated gastro-intestinal conditions. Int J Food Sci Nutr 64(3):380–384. https://doi.org/10.3109/09637486.2012.749841

Gbassi GK, Vandamme T, Ennahar S, Marchioni E (2009) Microencapsulation of Lactobacillus plantarum spp in an alginate matrix coated with whey proteins. Int J Food Microbiol 129(1):103–105. https://doi.org/10.1016/j.ijfoodmicro.2008.11.012

Yeung TW, Ucok EF, Tiani KA, McClements DJ, Sela DA (2016) Microencapsulation in alginate and chitosan microgels to enhance viability of Bifidobacterium longum for oral delivery. Front Microbiol 7:34–39

Fahimdanesh M, Mohammadi N, Ahari H, Zanjani MA, Hargalani FZ, Behrouznasab K (2013) Effect of microencapsulation plus resistant starch on survival of Lactobacillus casei and Bifidobacterium bifidum in mayonnaise sauce. Afr J Microbiol Res 6:6853–6858

Zanjani MA, Tarzi BG, Sharifan A, Mohammadi N (2014) Microencapsulation of probiotics by calcium alginate-gelatinized starch with chitosan coating and evaluation of survival in simulated human gastro-intestinal condition. Iran J Pharm Res 13:843–850

Dong QY, Chen MY, Xin Y, Qin XY, Chen Z, Shi LE (2013) Alginate-based and protein-based materials for probiotics encapsulation: a review. Int J Food Sci Technol 48(7):1339–1351. https://doi.org/10.1111/ijfs.12078

Duongthingoc D, George P, Katopo L, Gorczyca E, Kasapis S (2013) Effect of whey protein agglomeration on spray dried microcapsules containing Saccharomyces boulardii. Food Chem 141(3):1782–1788. https://doi.org/10.1016/j.foodchem.2013.04.093

Anandharamakrishnan C, Rielly CD, Stapley AGF (2012) Effects of process variables on the denaturation of whey proteins during spray-drying. Dry Technol 25:799–807

Ayama H, Punnanee S, Songklanakarin SC (2014) Effect of encapsulation of selected probiotic cell on survival in simulated gastrointestinal tract condition. J Adhes Sci Technol 36:291–299

Cook SM, Cho YH, Huh CS, Baek YJ, Park J (2011) Improvement of the stability of Lactobacillus casei YIT 9018 by microencapsulation using alginate and chitosan. J Microbiol Biotechnol 11:376–383

Lotfipour SM, Maghsoodi M (2012) Evaluation of the effect of CaCl2 and alginate concentrations and hardening time on the characteristics of Lactobacillus acidophilus loaded alginate beads using response surface analysis. Afr J Microbiol Res 2:71–78

Lee IC, Tomita S, Kleerebezem M, Bron PA (2013) The quest for probiotic effector molecules-unraveling strain specificity at the molecular level. Pharmacol Res 69(1):61–74. https://doi.org/10.1016/j.phrs.2012.09.010

Wang J, Korber DR, Low NH, Nickerson MT (2014) Entrapment, survival and release of Bifidobacterium adolescentis within chickpea protein-based microcapsules. J Food Res Int 55:20–27. https://doi.org/10.1016/j.foodres.2013.09.018

Montgomery DC (2008) Design and analysis of experiments.7th Ed. John Wiley and sons. Inc. Hookon, NJ, USA. 1-656

Babu G, Rath S, Nithyalakshami V (2011) Probiotic viability of freeze dried symbiotic microcapsules in skim milk powder at ambient storage condition. Int J Food Safety 13:62–68

Dianawati D, Mishra V, Shah NP (2013) Survival of Bifidobacterium longum 1941 microencapsulated with proteins and sugars after freezing and freeze drying. Food Res Int 51(2):503–509. https://doi.org/10.1016/j.foodres.2013.01.022

Bampi GB, Backes GT, Cansian RL, de Matos FE, Ansolin IMA, Poleto BC, Corezzolla LR, Favaro-Trindade CS (2016) Spray chilling microencapsulation of Lactobacillus acidophilus. Food Biopro Technol 9(8):1422–1428. https://doi.org/10.1007/s11947-016-1724-z

Arslan-Tontul S, Erbas M (2017) Single and double layered microencapsulation of probiotics by spray drying and spray chilling. LWT-Food Sci Technol 81:160–169. https://doi.org/10.1016/j.lwt.2017.03.060

de Lara Pedroso D, Thomazini M, Heinemann RJB, Favaro-Trindade CS (2012) Protection of Bifidobacterium lactis and Lactobacillus acidophilus by microencapsulation using spray-chilling. Int Dairy J 26(2):127–132. https://doi.org/10.1016/j.idairyj.2012.04.008

Krasaekoopt W, Bhandari B, Deeth H (2004) The influence of coating materials on some properties of alginate beads and survivability of microencapsulated probiotic bacteria. Int Dairy J 14(8):737–743. https://doi.org/10.1016/j.idairyj.2004.01.004

Nualkaekul S, Lenton D, Cook MT, Khutoryanskiy VV, Charalampopoulos D (2012) Chitosan coated alginate beads for the survival of microencapsulated Lactobacillus plantarum in pomegranate juice. Carbohydr Polym 90(3):1281–1287. https://doi.org/10.1016/j.carbpol.2012.06.073

Falco CY, Sotres J, Rascon A, Risbo J, Cardenas M (2017) Design of a potentially prebiotic and responsive encapsulation material for probiotic bacteria based on chitosan and sulfated β-glucan. J. Colloid Interface Sci 487:97–106. https://doi.org/10.1016/j.jcis.2016.10.019

Sahadeva RPK, Leong SF, Chua KH, Tan CH, Chan HY, Tong EV, Wong SYW, Chan HK (2011) Survival of commercial probiotic strains to pH and bile. Int Food Res J 18:1515–1522

Abbaszadeh S, Gandomi H, Misaghi A, Bokaei S, Noori N (2014) The effect of alginate and chitosan concentrations on some properties of chitosan-coated alginate beads and survivability of encapsulated Lactobacillus rhamnosus in simulated gastrointestinal conditions and during heat processing. J Sci Food Agr 94(11):2210–2216. https://doi.org/10.1002/jsfa.6541

Chandramouli V, Kailasapathy K, Peiris P, Jones M (2004) An improved method of microencapsulation and its evaluation to protect lactobacillus spp. in simulated gastric conditions. J Microbiol Meth 56:27–35

Heidebach T, Först P, Kulozik U (2009) Microencapsulation of probiotic cells by means of rennet-gelation of milk proteins. Food Hydrocoll 23(7):1670–1677. https://doi.org/10.1016/j.foodhyd.2009.01.006

Moumita S, Goderska K, Johnson EM, Das B, Indira D, Yadav R, Kumari S, Jayabalan R (2017) Evaluation of the viability of free and encapsulated lactic acid bacteria using in-vitro gastro intestinal model and survivability studies of symbiotic microcapsules in dry food matrix during storage. LWT-Food Sci Technol 77:460–467. https://doi.org/10.1016/j.lwt.2016.11.079

Shi LE, Zhang ZL, Song YQ, Zhou ML, WM Y, Tang ZX (2013b) Encapsulation of Lactobacillus bulgaricus in carrageenan-locust bean gum coated milk microspheres with double layer structure. LWT-Food Sci Technol 54(1):147–151. https://doi.org/10.1016/j.lwt.2013.05.027

Kamalian N, Mirhosseini H, Mustafa S, Manap MYA (2014) Effect of alginate and chitosan on viability and release behavior of Bifidobacterium pseudocatenulatum G4 in simulated gastrointestinal fluid. Carbohydr Polym 11:700–706

Argin S, Kofinas P, Lo YM (2014) The cell release kinetics and the swelling behavior of physically cross-linked xanthan–chitosan hydrogels in simulated gastrointestinal conditions. Food Hydrocol 40:138–144. https://doi.org/10.1016/j.foodhyd.2014.02.018

Chen MY, Zheng W, Dong QY, Li ZH, Shi LE (2014) Tang ZX activity of encapsulated Lactobacillus bulgaricus in alginate-whey protein microspheres. Braz Arch Biol Technol 57(5):736–741. https://doi.org/10.1590/S1516-8913201402377

Mandal S, Puniya AK, Singh K (2006) Effect of alginate concentrations on survival of microencapsulated Lactobacillus casei NCDC-298. Int Dairy J 16(10):1190–1195. https://doi.org/10.1016/j.idairyj.2005.10.005

Picot A, Lacroix C (2004) Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yoghurt. Int Dairy J 14(6):505–515. https://doi.org/10.1016/j.idairyj.2003.10.008

Rao AV, Shiwnarain N, Maharaj I (1989) Survival of microencapsulated Bifidobacterium pseudolongum in simulated gastric and intestinal juices. Canadian Int Food Sci Tech J 22(4):345–349. https://doi.org/10.1016/S0315-5463(89)70426-0

Klemmer KJ, Korber DR, Low NH, Nickerson MT (2011) Pea protein-based capsules for probiotic and prebiotic delivery. Int J Food Sci Tech 46(11):2248–2256. https://doi.org/10.1111/j.1365-2621.2011.02743.x

Tian S, Ohta A, Horiuchi H, Fukuda R (2015) Evaluation of sterol transport from the endoplasmic reticulum to mitochondria using mitochondrially targeted bacterial sterol acyl-transferase in Saccharomyces cerevisiae. Biosci Biotechnol Biochem 79(10):1608–1614. https://doi.org/10.1080/09168451.2015.1058702

Zhang L, Zhang X, Liu C, Li C, Li S, Li T, Li D, Zhao Y, Yang Z (2013) Manufacture of cheddar cheese using probiotic Lactobacillus plantarum K25 and its cholesterol-lowering effects in a mice model. World J Microbiol Biotech 29:127–135

Gerez CL, Font de Valdez G, Gigante ML, Grosso CRF (2012) Whey protein coating bead improves the survival of the probiotic Lactobacillus rhamnosus CRL 1505 to low pH. Lett Appl Microbiol 54(6):552–556. https://doi.org/10.1111/j.1472-765X.2012.03247.x

Nieddu M, Rassu G, Boatto G, Bosi P, Trevisi P, Giunchedi P, Carta A, Gavini E (2014) Improvement of thymol properties by complexation with cyclodextrins: in vitro and in vivo studies. Carbohydr Polym 102:393–399. https://doi.org/10.1016/j.carbpol.2013.10.084

de Vos P, Faas MM, Spasojevic M, Sikkema J (2010) Encapsulation for preservation of functionality and targeted delivery of bioactive food components. Int Dairy J 20(4):292–302. https://doi.org/10.1016/j.idairyj.2009.11.008

Cruce PS (2001) Improving probiotic survival rates. Food Tech 55:36–43

Acknowledgements

We acknowledge colleagues and institutions of National Institute of Food Science and Technology, University Faisalabad, HEC, and School of Food Science, UI (University of Idaho) in the College of Agricultural and Life Sciences (CALS) for providing moral, funding, and laboratory support and their contributions. Special thanks are for Dr. Gulhan Unlu and Dr. Boffman, UI, USA and Dr. Tahir Zahoor, Dr. Nuzhat Huma, and Dr. Amer Jamil UAF-Pakistan for providing all guidelines in the field of study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Iqbal, R., Zahoor, T., Huma, N. et al. In-vitro GIT Tolerance of Microencapsulated Bifidobacterium bifidum ATCC 35914 Using Polysaccharide-Protein Matrix. Probiotics & Antimicro. Prot. 11, 830–839 (2019). https://doi.org/10.1007/s12602-017-9384-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-017-9384-5