Abstract

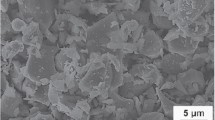

Ti-Mo getters have been fabricated via metal injection molding (MIM) using three kinds of Ti powders with different mean particle sizes of 46 μm, 35 μm and 26 μm, respectively. The surface morphology, porosity, and hydrogen sorption properties of Ti-Mo getters formed by MIM using paraffin wax as a principal binder constituent were examined. It has been proven that the powder injection molding is a viable forming technique for porous Ti-Mo getters. The particle size of Ti powders and the powder loading influence the porosity of getters, and this affects the sorption capacity of Ti-Mo getters. Ti-Mo getters produced with the Ti powders possessing a mean particle size of 35 μm using a powder loading of 40 vol.% have a high porosity, resulting in a good sorption capacity.

Similar content being viewed by others

References

Benvenuti C., Chiggiato P., Cicoira F., and Ruzinov V., Decreasing surface outgassing by thin film getter coatings, Vacuum, 1998, 50(1–2): 57.

Boffitto C., Doni F., and Rosai L.J., The properties of some zirconium-based gettering alloys for hydrogen isotope storage and purification. Less Common Met., 1984, 104(1): 149.

Heyder R., Watson L., Jackson R., Kruege G., and Conte A., Getters for reliable hermetic packages, Solid State Technol., 1996, 8(1): 71.

Barosi A. and Giorgi T.A., A non-evaporable getter for low temperature, Vacuum, 1973, 23(1): 15.

Giorgi E., Boffito C., and Bolognesi M., A new Ti-based non-evaporable getter, Vacuum, 1990, 41(7–9): 1935.

Benvenuti C. and Chiggiato P., Obtention of pressure in the 10−4 torr range by means of a Zr-V-Fe non evaporable getter, Vacuum, 1993, 44(1): 511.

Eberhard A. and Geory W., Matching P/M and the physics of magnetic materials, Int. J. Powder Metall., 1989, 25(4): 319.

Arnhold V., Chu C.L., Jandeska W.F., and Sanderow H.I, Advances in Powder Metallurgy and Particulate Materials, Metal Powder Industries Federation, NJ, 2002: 10.

Lyasnikov V.N., Obzory po electronnoi technike, MTSNII Electron., 1989, 1(7): 1423.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Z., Wei, X., Xiong, Y. et al. Preparation of Ti-Mo getters by injection molding. Rare Metals 28, 147–150 (2009). https://doi.org/10.1007/s12598-009-0029-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-009-0029-z