Abstract

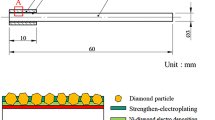

Diamond grits were brazed using Cu-Sn-Cr and Ni-Cr-B-Si filler metals, and the brazed grits were examined for microstructure (SEM, EDS, XRD), microhardness, and compression strength. Results showed that the microstructure of the Cu-based filler metal was uniform and consisted of α-Cu + (α-Cu + δ). Its wettability to the diamond was better than Ni-based filler due to the formation of a thin carbide reaction layer that improved the bond strength between the diamond and steel. The Cu-based filler led to reduced thermal damage to the diamond. The Cr in the filler metal diffused to the steel substrate to form a reaction layer at the filler/steel substrate interface. The microhardness of the Ni filler metal (810-830 HV0.3) was significantly higher than that of Cu filler metal (170-230 HV0.3). The compressive load values of the diamond grits brazed with Cu-based or Ni-based filler metal were 93.7 and 49.2% of the original diamond, and the TI values were 83.7 and 59.8% of the original diamond. Grinding experiments for failure mode in monolayer tools revealed that the tools brazed with Cu-based filler metal had a lower macro-fracture ratio than those brazed using the Ni-based filler.

Similar content being viewed by others

References

C.M. Sung, Brazed Diamond Grid: A Revolutionary Design for Diamond Saw, Diam. Relat. Mater., 1999, 8, p 1540–1543

A.K. Chattopadhyay, L. Chollet, and H.E. Hintermann, On Performance of Brazed-Bond Monolayer Diamond Grinding Wheel, Ann. CIRP, 1991, 40, p 347–350

W.F. Ding, J.H. Xu, Y.C. Fu, B. Xiao, H.H. Su, and H.J. Xu, Interfacial Reaction Between Cubic Boron Nitride and Ti During Active Brazing, J. Mater. Eng. Perform., 2006, 15(3), p 365–369

W.F. Ding, J.H. Xu, Z.Z. Chen, Q. Miao, and C.Y. Yang, Interface Characteristics and Fracture Behavior of Brazed Polycrystalline CBN Grains Using Cu-Sn-Ti Alloy, Mater. Sci. Eng., A, 2013, 559, p 629–634

C. Artini, M.L. Muolo, and A. Passerone, Diamond-Metal Interfaces in Cutting Tools: A Review, J. Mater. Sci., 2012, 47, p 3252–3264

W.F. Ding, Q. Miao, J.H. Xu, C.Y. Ma, B. Zhao, and C.Y. Yang, Joining Interface and Grain Fracture of Single-Layer Brazed Grinding Wheels with Binderless CBN Grains, Int. J. Adv. Manuf. Technol., 2013, 68, p 1261–1266

W.F. Ding, J.H. Xu, M. Shen, H.H. Su, Y.C. Fu, and B. Xiao, Joining of CBN Abrasive Grains to Medium Carbon Steel with Ag-Cu/Ti Powder Mixture as Active Brazing Alloy, Mater. Sci. Eng., 2006, A430, p 301–306

C.H. Lee, J.O. Ham, M.S. Song, and C.H. Lee, The Interfacial Reaction between Diamond Grit and Ni-Based Brazing Filler Metal, Mater. Trans., 2007, 48(4), p 889–891

C. Leinenbach, R. Transchel, K. Gorgievski, F. Kuster, H.R. Elsener, and K. Wegener, Microstructure and Mechanical Performance of Cu-Sn-Ti–Based Active Braze Alloy Containing In Situ Formed Nano-Sized TiC Particles, J. Mater. Eng. Perform., 2015, 24, p 2042–2050

T. Yamazaki and A. Suzumura, Reaction Products at Brazed Interface between Ag-Cu-V Filler Metal and Diamond (111), J. Mater. Sci., 2006, 41, p 6409–6416

Y.M. Zhou, F.L. Zhang, and Z.C. Xu, Cr Powder-Activated Induction Brazing of Diamond Grits with Ag-Cu-Zn Alloy, Mater. Manuf. Processes, 2008, 23, p 352–356

C.Y. Wang, Y.M. Zhou, F.L. Zhang, and Z.C. Xu, Interfacial Microstructure and Performance of Brazed Diamond Grits with Ni-Cr-P Alloy, J. Alloy. Compd., 2009, 476, p 884–888

C.Y. Ma, W.F. Ding, J.H. Xu, and Y.C. Fu, Influence of Alumina Bubble Particles on Microstructure and Mechanical Strength in Porous Cu-Sn-Ti Metals, Mater. Des., 2015, 65, p 50–56

Z. Li, W.F. Ding, L. Shen, X.X. Xi, and Y.C. Fu, Comparative Investigation on High-speed Grinding of TiCp/Ti–6Al–4 V Particulate Reinforced Titanium Matrix Composites with Single-layer Electroplated and Brazed CBN Wheels, Chin. J. Aeronaut., 2016, 29(5), p 1414–1424

C. Artini, M.L. Muolo, and A. Passerone, Diamond-Metal Interfaces in Cutting Tools: A Review, J. Mater. Sci., 2012, 47, p 3252–3264

S.J. Zhang, S. To, and G.Q. Zhang, Diamond Tool Wear in Ultra-precision Machining, Int. J. Adv. Manuf. Technol., 2016, 88(1–4), p 613–641

Y. Chen, Y.C. Fu, H.H. Su, J.H. Xu, and H.J. Xu, The Effects of Solder Alloys on The Morphologies and Mechanical Properties of Brazed Diamond Grits, Int. J. Refract. Met. Hard Mater., 2014, 42, p 23–29

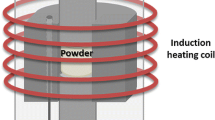

B.J. Ma and H.D. Zhu, A Study on Induction Brazing of Diamond Grits Using both Amorphous and Crystalline Ni-Based Filler alloy, Int. J. Adv. Manuf. Technol., 2016, 86, p 1607–1613

S. Buhl, C. Leinenbach, R. Spolenak, and K. Wegener, Failure Mechanisms and Cutting Characteristics of Brazed Single Diamond Grains, Int. J. Adv. Manuf. Technol., 2013, 66, p 775–786

S.F. Huang, H.L. Tsai, and S.T. Lin, Laser Brazing of Diamond Grits Using a Cu–15Ti–10Sn Brazing Alloy, Mater. Trans., 2002, 43(10), p 2604–2608

M. Nomura, T. Ichimori, and C. Iwamoto, Structure of Wetting Front in the Ag-Cu-Ti/SiC Reactive System, J. Mater. Sci., 2000, 35(16), p 3593–3958

M. Nomura, C. Iwamoto, and S.I. Tanaka, Nanostructure of Wetting Triple Line on A Ag-Cu-Ti/Si3N4 Reactive System, Acta Mater., 1999, 47, p 407–413

S. Buhl, C. Leinenbach, R. Spolenak, and K. Wegener, Microstructure, Residual Stresses and Shear Strength of Diamond-Steel-Joints Brazed with A Cu-Sn-Based Active Filler alloy, Int. J. Refract. Met. Hard Mater., 2012, 30, p 16–24

Hiroaki Okamoto, Supplemental Literature Review of Binary Phase Diagrams: Bi-Ce, Bi-Er, C-Ce, C-La, C-Pr, Cd-I, Cr-Cu, Cu-Er, Er-Sb, F-Sm, F-Yb, and Fe-Gd, JPEDAV, 2013, 34, p 350–362

Y.L. Yuan and Z.G. Li, Microstructure and Wear Performance of High Volume Fraction Carbide M7C3 Reinforced Fe-based Composite Coating Fabricated by Plasma Transferred Arc Welding, J. Wuhan Univ. Technol. Mater., 2014, 29(5), p 1028–1035

J.B. Lu, P. Meng, B. Zhao, and J.J. Liu, Nucleation and Growth of Cr7C3 of Brazing Diamond with Ni-Cr Alloy in Protective Atmosphere Furnace, Adv. Mater. Res., 2012, 463–464, p 505–509

L. Jinbin and X. Jiuhua, Interface Microstructure and Thermal Stress of Diamond Brazing with Ag-Cu-Ti Filler, Rare Met. Mater. Eng., 2009, 38, p 642–646 (in Chinese)

Acknowledgments

The authors gratefully acknowledge the fund projects of Suzhou University of Science and Technology of China (No. XKZ201501) and fund of the State Key Laboratory of Advanced Brazing Filler Metals and Technology of China (No. SKLABFMT201003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, W., Lu, J., Li, Y. et al. Vacuum Brazing Diamond Grits with Cu-based or Ni-based Filler Metal. J. of Materi Eng and Perform 26, 4112–4120 (2017). https://doi.org/10.1007/s11665-017-2804-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2804-6