Abstract

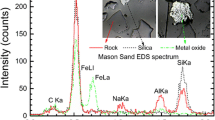

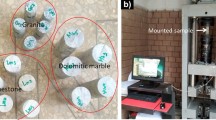

Characterization was made on the structure and grain-level mechanical behavior of Eglin sand (Quikrete #1961 sand quarried in Pensacola, FL). The as-received assorted sand was sorted to six grain sizes: 0.60 mm, 0.50 mm, 0.42 mm, 0.30 mm, 0.212 mm, and 0.15 mm. The sand chemical constituents and crystalline structures were determined using energy dispersive X-ray spectroscopy, X-ray diffraction and transmission electron microscopy. The Young’s modulus and hardness were determined using nanoindentation with a Berkovich tip, and the fracture toughness was measured using a cube-corner tip. The median Young’s modulus, hardness and fracture toughness were determined as 90.4 GPa, 12.8 GPa and 2.32 MPa⋅m0.5, respectively. The mechanical properties were analyzed statistically and the parameters of the Weibull distribution were determined. The grains show highly ductile behavior under nanoindentation due to confinement by high pressure induced by Berkovich tip. An inverse problem solving approach using finite element method (FEM) with the consideration of the Ramberg-Osgood model was used to determine the stress–strain relationship for individual sand grains.

Similar content being viewed by others

References

Yamamuro JA, Bopp PA, Lade PV (1996) One-dimensional compression of sands at high pressure. J Geotech Eng 122:147–154. doi:10.1061/(ASCE)0733-9410(1996)122:2(147)

Russell AR, Khalili N (2004) A bounding surface plasticity model for sands exhibiting particle crushing. Can Geotech J 41:1179–1192. doi:10.1139/t04-065

Vallejos J (2008) Hydrostatic compression model for sandy soils. Can Geotech J 45:1169–1179. doi:10.1139/T08-048

Graham J, Alfaro M, Ferris G (2004) Compression and strength of dense sand at high pressure and elevated temperatures. Can Geotech J 41:1206–1212. doi:10.1139/T04-047

Cheung LYG, O’Sullivan C, Coop MR (2013) Discrete element method simulations of analogue reservoir sandstones. Int J Rock Mech Min Sci 63:93–103. doi:10.1016/j.ijrmms.2013.07.002

Widulinski Ł, Tejchman J, Kozicki J, Lesniewska J (2011) Discrete simulations of shear zone patterning in sand in earth pressure problems of a retaining wall. Int J Solids Struct 48:1191–1209. doi:10.1016/j.ijsolstr.2011.01.005

Longmore J-P, Marais P, Kuttel MM (2013) Towards realistic and interactive sand simulation: a GPU-based framework. Powder Technol 235:983–1000. doi:10.1016/j.powtec.2012.10.056

Dwivedi SK, Teeter RD, Felice CW, Gupta YM (2008) Two dimensional mesoscale simulations of projectile instability during penetration in dry sand. J Appl Phycol 104:083502. doi:10.1063/1.2999391

Hicher PY, Chang CS, Dano C (2008) Multi-scale modeling of grouted sand behavior. Int J Solids Struct 45:4362–4374. doi:10.1016/j.ijsolstr.2008.03.024

Borg JP, Vogler TJ (2008) Mesoscale simulations of a dart penetrating sand. Int J Impact Eng 35:1435–1440. doi:10.1016/j.ijimpeng.2008.07.064

Antoun T, Herbold E, Johnson S (2012) Dynamic behavior of sand: annual report FY 11. Lawrence Livermore National Laboratory, LLNL-TR-539077

Borja RI, Andrade JE (2006) Critical state plasticity. Part VI: meso-scale finite element simulation of strain localization in discrete granular materials. Comput Methods Appl Mech Eng 195:5115–5140. doi:10.1016/j.cma.2005.08.020

Daphalapurkar NP, Wang F, Fu B, Lu H, Komanduri R (2010) Determination of mechanical properties of sand grains by nanoindentation. Exp Mech 51:719–728. doi:10.1007/s11340-010-9373-z

Poorooshasb HB, Holubec I, Sherbourne AN (1966) Yielding and flow of sand in triaxial compression part I. Can Geotech J 3(4):179–190. doi:10.1139/t66-023

Lade PV, Duncan JM (1973) Cubical triaxial tests on cohesionless soil. J Soil Mech Found Div 99(10):793–812

Arthur JRF, Menzies BK (1972) Inherent anisotropy in a sand. Geotech 22(1):115–128

Lade PV, Prabucki MJ (1995) Softening and preshearing effects in sand. Soils Found 5(4):93–104

Desrues J, Lanier J, Stutz P (1985) Localization of the deformation in tests on sand sample. Eng Fract Mech 21(4):909–921. doi:10.1016/0013-7944(85)90097-9

Wang Q, Lade PV (2001) Shear banding in true triaxial tests and its effect on failure in sand. J Eng Mech 127(8):754–776. doi:10.1061/(ASCE)0733-9399(2001)127:8(754)

Haythornthwaite R (1997) Simple shear in granular media. Appl Mech Rev 50(11):81–86. doi:10.1115/1.3101854

Martin BE, Chen W, Song B, Akers SA (2009) Moisture effects on the high strain-rate behavior of sand. Mech Mater 41:786–798. doi:10.1016/j.mechmat.2009.01.014

Proud WG, Chapman DJ, Williamson DM, Tsembelis K, Addiss J et al (2007) The dynamic compaction of sand and related porous systems. Shock Compression Condens Matter 955:1403–1408. doi:10.1063/1.2832988

Lade PV, Wang Q (2012) Method for uniform strain extension tests on sand. Geotech Test J 35(4). doi:10.1520/GTJ103852

Yamauro J, Abrantes AE, Lade PV (2011) Effect of strain rate on the stress–strain behavior of sand. J Geotech Geoenviron Eng 137(12):1169–1178

Pethicai JB, Hutchings R, Oliver WC (1983) Hardness measurement at penetration displacements as small as 20 nm. Philos Mag A 48:593–606. doi:10.1080/01418618308234914

Li X, Bhushan B (2002) A review of nanoindentation continuous stiffness measurement technique and its applications. Mater Charact 48:11–36. doi:10.1016/S1044-5803(02)00192-4

Kucuk Y, Mollamahmutoglu C, Wang Y, Lu H (2013) Nonlinearly viscoelastic nanoindentation of PMMA under a spherical tip. Exp Mech 53:731–742. doi:10.1007/s11340-012-9695-0

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. doi:10.1557/JMR.1992.1564

Goldenberg C, Goldhirsch I (2005) Friction enhances elasticity in granular solids. Nature 435:188–191. doi:10.1038/nature03497

Geng J, Howell E, Behringer R, Reydellet G, Vanel L, Clement E, Luding S (2001) Footprints in sand: the response of a granular material to local perturbations. Phys Rev Lett 87(3):35506. doi:10.1103/PhysRevLett.87.035506

Oda M, Konishi J, Nemat-Nasser S (1980) Some experimentally based fundamental results on the mechanical behavior of granular materials. Geotech 30(4):479–495

Dutta AK, Penumadu D (2007) Hardness and modulus of individual sand particles using nanoindentation. Geotech 173:1–10. doi:10.1061/40917(236)34

Buchheit TE, Vogler TJ (2010) Measurement of ceramic powders using instrumented indentation and correlation with their dynamic response. Mech Mater 42:599–614. doi:10.1016/j.mechmat.2010.02.007

Taylor LJ, Papadopoulos DG, Dunn PJ, Bentham AC, Mitchell JC, Snowden MJ (2004) Mechanical characterisation of powders using nanoindentation. Powder Technol 143:179–185. doi:10.1016/j.powtec.2004.04.012

Luo H, Lu H, Cooper WL, Komanduri R (2011) Effect of mass density on the compressive behavior of dry sand under confinement at high strain rates. Exp Mech 51:1499–1510. doi:10.1007/s11340-011-9475-2

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res 19(1):3–20

Pharr GM, Harding DS, Oliver WC (1993) Measurement of fracture toughness in thin films and small volumes using nanoindentation method. In: Nastasi M, Parkin DM, Gleiter H (eds) Mechanical properties and deformation behavior of materials having ultra-fine microstructures. Kluwer Academic Publishers, pp. 449–461

Papoulis A, Pillai SU (2002) Probability, random variables, and stochastic processes. McGraw-Hill Education

Weibull W (1951) A statistical distribution function of wide applicability. JAppl Mech Trans ASME 18(3):293–297

Luo H, Cooper WL, Lu H (2014) Effect of particle size and moisture on the compressive behavior of dense Eglin sand under confinement at high strain rates. Int J Impact Eng 65:40–55

National Institute of Standards and Technology, SEMATECH (2006) e-Handbook of Statistical Methods. (http://www.itl.nist.gov/div898/handbook/eda/section3/eda3668.htm)

Osgood WR, Ramberg W (1943) Description of stress–strain curves by three parameters, NACA Technical Note 902. National Bureau of Standards, Washington

Bildhauer M, Fuchs M (2007) Continuity properties of the stress tensor in the 3-dimensional Ramberg/Osgood model. J Appl Anal 13(2):209–233

Shim S, Jang J, Pharr GM (2008) Extraction of flow properties of single-crystal silicon carbide by nanoindentation and finite-element simulation. Acta Mater 56:3824–3832. doi:10.1016/j.actamat.2008.04.013

Tabor D (1951) The hardness of metals. Oxford University Press, Oxford

Atkins AG, Tabor D (1965) Plastic indentation in metals with cones. J Mech Phys Solids 13:149–164. doi:10.1016/0022-5096(65)90018-9

Jayaraman S, Hahn GT, Oliver WC, Rubin CA, Bastias PC (1998) Determination of monotonic stress–strain curve of hard materials from ultra-low-load indentation tests. Int J Solids Struct 35:365–381. doi:10.1016/S0020-7683(97)89371-7

Cheng Y, Li Z (2000) Hardness obtained from conical indentation with various cone angles. J Mater Res 15:2830–2835. doi:10.1557/JMR.2000.0404

Sakai M, Akatsu T, Numata S, Matsuda K (2003) Linear strain hardening in elastoplastic indentation contact. J Mater Res 18:2087–2096. doi:10.1557/JMR.2003.0293

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

ABAQUS version 6.9 documentation (2009) Dassault Systèmes, Providence, RI, USA

Harding DS (1995) Cracking during nanoindentation and its use in the measurement of fracture toughness. In: Baker SP (ed) Thin films-stresses and mechanical properties V, MRS symposium proceeding, 356, 663–668

Bolshakov A, Pharr GM (1998) Influence of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J Mater Res 13(4):1049–1058. doi:10.1557/JMR.1998.0146

Calderon E, Gauthier M, Decremps F, Hamel G, Syfosse G, Polina A (2007) Complete determination of the elastic moduli of α-quartz under hydrostatic pressure up to 1 GPa. J Phys Condens Matter 19:1–13. doi:10.1088/0953-8984/19/43/436228

Shield RT (1955) On the plastic flow of metals under conditions of axial symmetry. Proc R Soc Lond A233:267–287. doi:10.1098/rspa.1955.0262

Tabor D (1970) The hardness of solids. Rev Phys Technol 1:145–179. doi:10.1088/0034-6683/1/3/I01

Johnson KL (1970) The correlation of indentation experiments. J Mech Phys Solids 18:115–126. doi:10.1016/0022-5096(70)90029-3

Bhattacharya AK, Nix WD (1988) Finite element simulation of indentation experiments. Int J Solids Struct 24:881–891. doi:10.1016/0020-7683(88)90039-X

Liu Y, Wang B, Yoshino M, Roy S, Lu H, Komanduri R (2005) Combined numerical simulation and nanoindentation for determining mechanical properties of single crystal copper at mesoscale. J Mech Phys Solids 53:2718–2741. doi:10.1016/j.jmps.2005.07.003

Wang HF, Bangert H (1993) Three-dimensional finite element simulation of Vickers indentation on coated systems. Mater Sci Eng A163:43–50. doi:10.1016/0921-5093(93)90576-Z

Fivel MC, Robertson CF, Canova GR, Boulanger L (1998) Three-dimensional modeling of indent-induced plastic zone at a mesoscale. Acta Mater 46:6183–6194. doi:10.1016/S1359-6454(98)00278-X

Acknowledgments

We acknowledge the support of ONR MURI BAA 10-026, DOE NEUP 09-818, AFOSR DEPSCoR FA9550-08-1-0328, and NSF under CMMI-0619803, CMMI-1031829, DMR-0907291, CMMI-1132174, and ECCS-1307997. Lu also thanks the Louis A. Beecherl Jr. Chair for additional support. Mirshams acknowledges partial support from UNT Office of Sponsored Research. Park and Kim acknowledge the support from the State of Texas ETF.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is dedicated to Dr. Ranga Komanduri, who passed away on September 6, 2011 in Stillwater, Oklahoma.

Rights and permissions

About this article

Cite this article

Wang, F., Fu, B., Luo, H. et al. Characterization of the Grain-Level Mechanical Behavior of Eglin Sand by Nanoindentation. Exp Mech 54, 871–884 (2014). https://doi.org/10.1007/s11340-013-9845-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9845-z