Abstract

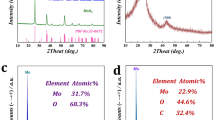

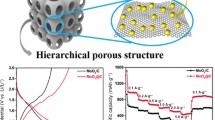

Copper-supported MoO2-C composite as an integrated anode with excellent battery performance was synthesized by a facile knife coating technique followed by heat treatment in a vacuum. The obtained samples were characterized by X-ray diffraction (XRD), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), thermal analysis, nitrogen adsorption and desorption analysis, field emission scanning microscopy (FESEM), and transmission electron microscopy (TEM). The results show the MoO2-C composite coating is comprised of a porous carbon matrix with a pore size of 1–3 nm and ultrafine MoO2 nanoparticles with a size of 5–10 nm encapsulated inside, the coating is tightly attached on the surface of copper foil, and the interface between them is free of cracks. Stable PAN-DMF-H2O system containing ammonium molybdate suitable for knife coating technique and the MoO2-C composite with ultrafine MoO2 nanoparticles encapsulated in the carbon matrix can be prepared through controlling amount of added ammonium molybdate solution. The copper-supported MoO2-C composite coating can be directly utilized as the integrated anode for lithium-ion batteries (LIBs). It delivers a capacity of 814 mA h g−1 at a current density of 100 mA g−1 after 100 cycles without apparent capacity fading. Furthermore, with increase of current densities to 200, 500, 1000, 2000, and 5000 mA g−1, it exhibits average capacities of 809, 697, 568, 383, and 188 mA h g−1. Its outstanding electrochemical performance is attributed to combined merits of integrated anode and structure with ultrafine MoO2 nanoparticles embedded in the porous carbon matrix.

Similar content being viewed by others

References

Baltrusaitis J, Mendoza-Sanchez B, Fernandez V, Veenstra R, Dukstiene N, Roberts A, Fairley N (2015) Generalized molybdenum oxide surface chemical state XPS determination via informed amorphous sample model. Appl Surf Sci 326:151–161

Cao KZ, Jiao LF, Liu HQ, Liu YC, Wang YJ, Guo ZJ, Yuan HT (2015) 3D hierarchical porous alpha-Fe O nanosheets for high-performance lithium-ion batteries. Adv Energy Mater 5:1401–1421

Chen A, Yin LW, Qi YX (2013) MoO /ordered mesoporous carbon hybrids as anode materials with highly improved rate capability and reversible capacity for lithium-ion battery. Phys Chem Chem Phys 15:13601–13610

Dou YH, Xu JT, Ruan BY, Liu QN, Pan YD, Sun ZQ, Dou SX (2016) Atomic layer-by-layer Co O /graphene composite for high performance lithium-ion batteries. Adv Energy Mater:1501835–1501842

Duan LH, Huang YD, Jia DZ, Wang XC, Guo ZP (2012) Fe O fuzzy spheroids as anode materials for lithium-ion batteries. Mater Lett 71:151–153

Gao MX, Chen X, Pan HG, Xiang LS, Wu F, Liu YF (2010) Ultrafine SnO dispersed carbon matrix composites derived by a sol-gel method as anode materials for lithium ion batteries. Electrochim Acta 55:9067–9074

Gao H, Liu CL, Liu Y, Liu ZH, Dong WS (2014) MoO -loaded porous carbon hollow spheres as anode materials for lithium-ion batteries. Mater Chem Phys 147:218–224

Gu CD, Mai YJ, Zhou JP, You YH, Tu JP (2012) Non-aqueous electrodeposition of porous tin-based film as an anode for lithium-ion battery. J Power Sources 214:200–207

Hassan MF, Rahman MM, Guo ZP, Chen ZX, Liu HK (2010) SnO -NiO-C nanocomposite as a high capacity anode material for lithium-ion batteries. J Mater Chem 20:9707–9712

Hou XH, Zhang WL, Wang XY, Hu SJ, Li CM (2015) Soft template PEG-assisted synthesis of Fe O @C nanocomposite as superior anode materials for lithium-ion batteries. Sci Bull 60:884–891

Huang YD, Dong ZF, Jia DZ, Guo ZP, Cho W (2011a) Electrochemical properties of α-Fe O /MWCNTs as anode materials for lithium-ion batteries. Solid State Ionics 201:54–59

Huang YD, Dong ZF, Jia DZ, Guo ZP, Cho W (2011b) Preparation and characterization of core-shell structure Fe O /C nanoparticles with unique stability and high electrochemical performance for lithium-ion battery anode material. Electrochim Acta 56:9233–9239

Huang YG, Pan QC, Wang HQ, Yan ZX, Yang GH, Chen YH, Wu Q, Li QY (2016) Sn/SnO embedded in carbon nanosheets as high-performance anode material for lithium ion battery. Ceram Int 42:4586–4593

Jung HR, Lee WJ (2011) Electrochemical characterization of electrospun SnO -embedded carbon nanofibers anode for lithium ion battery with EXAFS analysis. J Electroanal Chem 662:334–342

Kim DH, Lee DH, Kim JS, Moon JH (2012) Electrospun Ni-added SnO −carbon nanofiber composite anode for high-performance lithium-ion batteries. ACS Appl Mater Interfaces 4:5408–5415

Li HP, Wei YQ, Zhang YG, Zhang CW, Wang GK, Zhao Y, Yin FX, Bakenov Z (2016) In situ sol-gel synthesis of ultrafine ZnO nanocrystals anchored on graphene as anode material for lithium-ion batteries. Ceram Int 42:12371–12377

Liu YP, Huang K, Fan Y, Zhang Q, Sun F, Gao T, Yang LW, Zhong JX (2013) Three-dimensional network current collectors supported Si nanowires for lithium-ion battery applications. Electrochim Acta 88:766–771

Liu XL, Ji WX, Liang JY, Peng LM, Hou WH (2014) MoO @carbon hollow microspheres with tunable interiors and improved lithium-ion battery anode properties. Phys Chem Chem Phys 16:20570–20577

Liu QN, Dou YH, Ruan BY, Sun ZQ, Chou SL, Dou SX (2016a) Carbon-coated hierarchical SnO hollow spheres for lithium ion batteries. Chem Eur J 22:5853–5857

Liu BY, Shao YF, Zhang YL, Zhang FH, Zhong N, Li WG (2016b) Highly efficient solid-state synthesis of carbonencapsulated ultrafine MoO nanocrystals as high rate lithium-ion battery anode. J Nanopart Res 18:375–384

Luo W, Hu XL, Sun YM, Huang YH (2011) Electrospinning of carbon-coated MoO nanofibers with enhanced lithium-storage properties. Phys Chem Chem Phys 13:16735–16740

Luo B, Qiu TF, Hao L, Wang B, Jin MH, Li XL, Zhi LJ (2016a) Graphene-templated formation of 3D tin-based foams for lithium ion storage applications with a long lifespan. J Mater Chem A 4:362–367

Luo B, Qiu TF, Ye DL, Wang LZ, Zhi LJ (2016b) Tin nanoparticles encapsulated in graphene backboned carbonaceous foams as high-performance anodes for lithium-ion and sodium-ion storage. 22:232–240

Ma YC, Huang YD, Wang XC, Jia DZ, Tang XC (2014) One-pot synthesis of Fe O /C nanocomposites by PEGassisted co-precipitation as anode materials for high-rate lithium-ion batteries. J Nanopart Res 16:2614–2622

Prahsarn C, Klinsukhon W, Roungpaisan N (2011) Electrospinning of PAN/DMF/H O containing TiO and photocatalytic activity of their webs. Mater Lett 65:2498–2501

Qian L, Wang XH, Qiao L, Sun XL, Li XW, Zheng YX, He DY (2013) Single electrospun porous NiO-ZnO hybrid nanofibers as anode materials for advanced lithium-ion batteries. Nano 5:3037–3042

Qin YL, Li F, Bai XB, Sun XL, Liu DQ, He DY (2015a) A novel Si film with Si nanocrystals embedded in amorphous matrix on cu foil as anode for lithium ion batteries. Mater Lett 138:104–106

Qin FR, Zhang K, Zhang LY, Li J, Lua H, Lai YQ, Zhang ZA, Zhou YM, Li YW, Fang J (2015b) Sustainable synthetic route for γ-Fe O /C hybrid as anode material for lithium-ion batteries. Dalton Trans 44:2150–2156

Song LX, Yang SJ, Wei W, Qu P, Xu MT, Liu Y (2015) Hierarchical SnO2 nanoflowers assembled by atomic thickness nanosheets as anode material for lithium ion battery. Sci Bull 60:982–985

Sun YM, Hu XL, Luo W, Huang YH (2011) Self-assembled hierarchical MoO /graphene nanoarchitectures and their application as a high-performance anode material for lithium-ion batteries. ACS Nano 5:7100–7107

Tang YP, Tan XX, Hou GY, Zheng GQ (2014) Nanocrystalline Li Ti O -coated TiO nanotube arrays as threedimensional anode for lithium-ion batteries. Electrochim Acta 117:172–178

Tang YP, Tang HL, Wu QL, Li JQ, Hou GY, Cao HZ, Wu LK, Zheng GQ (2016) TiO (B) nanowire arrays on Ti foil substrate as three-dimensional anode for lithium-ion batteries. Electrochim Acta 195:27–33

Wang ZY, Chen JS, Zhu T, Madhavi S, Lou XW (2010) One-pot synthesis of uniform carbon-coated MoO nanospheres for high-rate reversible lithium storage. Chem Commun 46:6906–6908

Wang BB, Wang G, Wang H (2014a) In situ synthesis of co O /cu electrode and its high performance for lithiumion batteries. Mater Lett 122:186–189

Wang JX, Zhang QB, Li XH, Xu DG, Wang ZX, Guo HJ, Zhang K (2014b) Three-dimensional hierarchical co O /CuO nanowire heterostructure arrays on nickel foam for high-performance lithium ion batteries. Nano Energy 6:19–26

Wu M, Li XW, Zhou Q, Ming H, Adkins J, Zheng JW (2014) Fabrication of Sn film via magnetron sputtering towards understanding electrochemical behavior in lithium-ion battery application. Electrochim Acta 123:144–150

Wu JX, Qin XY, Zhang HR, He YB, Li BH, Ke L, Lv W, Du HD, Yang QH, Kang FY (2015) Multilayered silicon embedded porous carbon/graphene hybrid film as a high performance anode. Carbon 84:434–443

Yang ZX, Du GD, Guo ZP, Yu XB, Chen ZX, Guo TL, Liu HK (2011) TiO (B)@carbon composite nanowires as anode for lithium ion batteries with enhanced reversible capacity and cyclic performance. J Mater Chem 21:8591–8596

Yang ZX, Du GD, Meng Q, Guo ZP, Yu XB, Chen ZX, Guo TL, Zeng R (2012a) Synthesis of uniform TiO @carbon composite nanofibers as anode for lithium ion batteries with enhanced electrochemical performance. J Mater Chem 22:5848–5854

Yang LC, Liu LL, Zhu YS, Wang XJ, Wu YP (2012b) Preparation of carbon coated MoO nanobelts and their high performance as anode materials for lithium ion batteries. J Mater Chem 22:13148–13152

Yang Q, Zhao JC, Sun T, Yu JY (2015) Enhanced performance of SnO -C composite fibers containing NiO as lithium-ion battery anodes. Ceram Int 41:11213–11220

Yoon S, Jung KN, Jin CS, Shin KH (2012) Synthesis of nitrided MoO and its application as anode materials for lithium-ion batteries. J Alloys Compd 536:179–183

Yu JY, Sun T, Yang Q, Ma JX (2016) Porous carbon networks containing Si and SnO as high performance anode materials for lithium-ion batteries. Mater Lett 184:169–172

Yu XL, Xiang HF, Long YH, Zhao N, Zhang XL, Xu J (2010) Preparation of porous polyacrylonitrile fibers by electrospinning a ternary system of PAN/DMF/H O. Mater Lett 64:2407–2409

Zeng LX, Zheng C, Deng CL, Ding XK, Wei MD (2013) MoO -ordered mesoporous carbon nanocomposite as an anode material for lithium-ion batteries. ACS Appl Mater Interfaces 5:2182–2187

Zhang X, Hu YA, Zhu DZ, Xie AJ, Shen YH (2016) A novel porous CuO nanorod/rGO composite as a high stability anode material for lithium-ion batteries. Ceram Int 42:1833–1839

Zhao HP, Jiang CY, He XM, Ren JG, Wan CR (2008) A novel composite anode for LIB prepared via template-likedirected electrodepositing cu-Sn alloy process. Ionics 14:113–120

Zhou M, Li XL, Wang B, Zhang YB, Ning J, Xiao ZC, Zhang XH, Chang YH, Zhi LJ (2015a) High-performance silicon battery anodes enabled by engineering graphene assemblies. Nano Lett 15:6222–6228

Zhou Y, Liu Q, Liu DB, Xie HX, Wu GX, Huang WF, Tian YF, He Q, Khalil A, Haleem YA, Xiang T, Chu WS, Zou CW, Song L (2015b) Carbon-coated MoO dispersed in three-dimensional graphene aerogel for lithium-ion battery. Electrochim Acta 174:8–14

Zhou E, Wang CG, Shao MH, Deng XL, Xu XJ (2017) MoO nanoparticles grown on carbon fibers as anode materials for lithium-ion batteries. Ceram Int 43:760–765

Funding

The funds of our work mainly came from Shanghai Municipal Education Commission (High-energy Beam Intelligent Processing and Green Manufacturing). We also appreciate Graduate Students Innovation Program of Shanghai University of Engineering Science (16KY0512) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 7012 kb).

Rights and permissions

About this article

Cite this article

Li, Q., Yang, Q., Zhao, Y. et al. Carbon-based coating containing ultrafine MoO2 nanoparticles as an integrated anode for high-performance lithium-ion batteries. J Nanopart Res 19, 332 (2017). https://doi.org/10.1007/s11051-017-4019-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-017-4019-z