Abstract

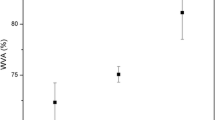

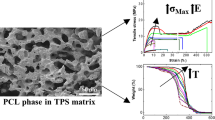

This paper describes the elaboration and characterization of biodegradable films from thermoplastic starch (TPS) and poly(ε-caprolactone) (PCL) blends. The films were obtained by a single screw extrusion process. Two PCLs of different molecular weights (37,000 and 50,000 g.mol−1, referred as PCL37 and PCL50) have been tested. Phase distribution of PCL and thermoplastic starch (TPS) has been characterized by FTIR, DSC and SEM. For the blend with PCL37, material surface is enriched with PCL, whereas in the blend with PCL50, TPS and PCL phases are more homogeneously distributed. Evolution of crystalline structure of the different formulations has been studied by X-ray diffraction, and mechanical properties by tensile tests. Maximal deformation of TPS/PCL blends is smaller than that of TPS, attesting the lack of compatibility between both polymers. Blending with PCL modifies the crystalline structure of TPS. Water resistance of the blends has been characterized by water sorption and water contact angle measurements. The decrease in water absorption for the blends was attributed to the decrease of starch content. At the surface of the material, water resistance of TPS/PCL50 blends is improved.

Similar content being viewed by others

References

Avérous L (2004) J Macromol Sci C Polym Rev 44:231–274

Hongsheng L, Fengwei X, Long Y, Ling C, Lin L (2009) Prog Polym Sci 34:1348–1368

Della Valle G, Kozlowski A, Colonna P, Tayeb J (1989) Lebensm Wiss Technol 22:279–286

Li G, Favis BD (2010) Macromol Chem Phys 211:321–333

Carvalho AJF (2013) In: Ebnesajjad S (ed) Handbook of biopolymers and biodegradable plastics. William Andrew Publishing, Boston

Van Tuil R, Fowler P, Lawther M, Weber CJ (2000) In: Weber CJ (ed) Biobased packaging materials for the food industry: status and perspectives. KVL, Frederiksberg

Dole P, Joly C, Espuche E, Alric I, Gontard N (2004) Carbohydr Polym 58:335–343

Follain N, Joly C, Dole P, Bliard C (2005) J Appl Polym Sci 97:1783–1794

Yu L, Dean K, Li L (2006) Prog Polym Sci 31:576–602

Huneault MA, Li HJ (2012) Appl Polym Sci 126:E96–E108

Senna MM, El-Shahat HA, El-Naggar AWM (2011) J Polym Res 18:763–771

Chaléat CM, Halley PJ, Truss RW (2012) Polym Degrad Stab 97:1930–1939

Yu F, Prashantha K, Soulestin J, Lacrampe MF, Krawczak P (2013) Carbohydr Polym 91:253–261

Dean K, Yu L, Bateman S, Wu DY (2007) J Appl Polym Sci 103:802–811

Myllymaki O, Myllarinen P, Forssel P, Suortti T, Lahteenkorva K, Ahvenainen R, Poutanen K (1998) Packag Technol Sci 11:265–274

Goldberg D (1995) J Polym Environ 3:61–67

Woodruff MA, Hutmacher DW (2010) Prog Polym Sci 35:1217–1256

Nien YH, Shih CY, Yang CY, Lu CJ, Ye QX (2013) J Polym Res 20:166–171

Chiono V, Vozzi G, D’Acunto M, Brinzi S, Domenici C, Vozzi F, Ahluwalia A, Barbani N, Giusti P, Ciardelli G (2009) Mater Sci Eng C 29:2174–2187

Averous L, Moro L, Dole P, Fringant C (2000) Polymer 41:4157–4167

Belard L, Dole P, Averous L (2009) Polym Eng Sci 49:1177–1186

Lee HC (2007) Physio-chemistry and rheology of Australian lentil flour and starch, and their implications for extrusion, Ph.D Thesis, University of New South Wales, Sydney, Australia

Stevenson DG, Biswas A, Jane JL, Inglett GE (2007) Carbohydr Polym 67:21–31

Lourdin D, Bizot H, Colonna P (1997) J Appl Polym Sci 63:1047–1053

Godbillot L, Dole P, Joly C, Rogé B, Mathlouthi M (2006) Food Chem 96:380–386

Greenspan L (1977) J Res Natl Bur Stand A Phys Chem 81A:89–96

Park GS (1986) In: Bungay PM, Lonsdale HK, Pinho MN (eds) Synthetic membranes: science, engineering and applications. Springer, Netherlands

Bessadok A, Langevin D, Gouanvé F, Chappey C, Roudesli S, Marais S (2009) Carbohydr Polym 76:74–85

Masclaux C, Gouanve F, Espuche E (2010) J Membr Sci 363:221–231

Alix S, Philippe E, Bessadok A, Lebrun L, Morvan C, Marais S (2009) Bioresour Technol 100:4742–4749

Owens DK, Wendt RC (1969) J Appl Polym Sci 13:1741–1747

Leblanc N, Saiah R, Beucher E, Gattin R, Castandet M, Saiter JM (2008) Carbohydr Polym 73:548–557

Rappenecker G, Zugenmaier P (1981) Carbohydr Res 89:11–19

Winter WT, Sarko A (1974) Biopolymers 13:1447–1460

Mercier C, Charbonniere R, Grebaut J, de la Gueriviere JF (1980) Cereal Chem 57:4–9

Van Soest J, Hulleman S, de Wit D, Vliegenthart J (1996) Ind Crop Prod 5:11–22

Lee K, Knight P, Chung T, Mather P (2008) Macromolecules 41:4730–4738

Seker M (2004) Int J Food Sci Technol 39:1053–1060

Wang Y, Rodriguez-Perez MA, Reis RL, Mano JF (2005) Macromol Mater Eng 290:792–801

Brunauer S, Emmett PH, Teller E (1938) J Am Chem Soc 60:309–319

Al-Muhtaseb AH, McMinn WAM, Magee TRA (2004) J Food Eng 61:297–307

Ayadi F, Dole P (2011) Carbohydr Polym 84:872–880

Chen H, Tang T, Amirfazli A (2012) Colloids Surf A 408:17–21

Eaton PJ, Graham P, Smith JR, Smart JD, Nevell TG, Tsibouklis J (2000) Langmuir 16:7887–7890

Shin BY, Lee S, Shin YS, Balakrishnan S, Narayan R (2004) Polym Eng Sci 44:1429–1438

Chaléat CM, Halley PJ, Truss RW (2008) Carbohydr Polym 71:535–543

Acknowledgments

The authors thank the Region Haute Normandie (France) for financial support through its research network VATA (AMI-AMIE project). We also thank the GPM UMR 6634 (University of Rouen) for XRD and SEM experiments.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mahieu, A., Terrié, C., Agoulon, A. et al. Thermoplastic starch and poly(ε-caprolactone) blends: morphology and mechanical properties as a function of relative humidity. J Polym Res 20, 229 (2013). https://doi.org/10.1007/s10965-013-0229-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0229-y