The effect of individual production factors on the heat tolerance of glass containers is studied. It is shown that the use of quartz raw material distinguished by its fineness from the material adopted for a technological process in a given glass-making furnace can result in massive production rejects, consisting in the appearance of seeds and heat intolerance. The phenomenon is explained from the standpoint of oscillations of the heat tolerance index of molten glass.

Similar content being viewed by others

References

K. G. Alekseeva, N. I. Vlasova, L. I. Demkina, and T. I. Mukhina, “Losses of light in glass,” in: Physical-Chemical Principles of Optical Glass Production [in Russian], edited by L. I. Demkina, Khimiya, Leningrad (1976), pp. 135 – 150.

Yu. A. Guloyan, Efficiency of the Technological Processes in the Production of Glass Articles [in Russian], Legkaya Promyshlennost’, Moscow (1982).

Yu. Guloyan and K. S. Kamkova, “Evaluation of the photo-protection and technological properties of container glass,” Steklo Keram., No. 7, 10 – 12 (1974).

H. Bach, F. G. K. Baukke, R. Bruekner, et al., Forms of Rejects in Glass Production [Russian translation], edited by N. N. Rokhlin, Stroiizdat, Moscow (1986).

N. I. Min’ko, “Effect of the oxidation-reduction potential of mix on the glassmaking process and the properties of glass,” in: Selected Works [in Russian], Izd. BGTU im. V. G. Shukhova, Belgorod (2004), pp. 23 – 32.

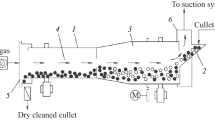

A. P. Sivko, A. I. Kovalenko, and L. P. Smirnova, “Role of glass in making molten glass and mechanized formation of glass articles. Pt. 2,” Glass Russia, No. 10, 16 – 19 (2007).

Yu. A. Guloyan, “Solidification of glass during formation (review),” Steklo Keram., No. 11, 3 – 7 (2004).

V. I. Kiyan and A. B. Atkarskaya, “Experience in using basicity indicators for evaluating the redox potential of molten glass in a continuous process,” Steklo Keram., No. 3, 9 – 13 (2002); V. I. Kiyan and A. B. Atkarskaya, “Experience in the use of basicity indicators to estimate the redox potential of molten glass in a continuous process,” Glass Ceram., 59(3 – 4), 84 – 88 (2002).

V. I. Kiyan, Yu. I. Mashir, and A. B. Atkarskaya, “Change of the redox potential of molten glass with introduction of melting catalyst into the mix,” Steklo Keram., No. 3, 5 – 7 (2000); V. I. Kiyan, Yu. I. Masir, and A. B. Atkarskaya, “Change in the redox potential of a glass melt upon introducing a melting catalyst into the glass batch,” Glass Ceram., 57(3 – 4), 78 – 80 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 10, pp. 13 – 17, October, 2010.

Rights and permissions

About this article

Cite this article

Atkarskaya, A.B., Raspopov, D.A., Chartii, P.V. et al. Heat tolerance of green glass containers. Glass Ceram 67, 307–311 (2011). https://doi.org/10.1007/s10717-011-9285-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-011-9285-0