Abstract

In the mid-latitudes, pigs and poultry are kept predominantly in confined livestock buildings with a mechanical ventilation system. In the last decades, global warming has already been a challenge which causes hat stress for animals in such systems. Heat stress inside livestock buildings was assessed by a simulation model for the indoor climate, which is driven by meteorological parameters. Besides the meteorological conditions, the thermal environment inside the building depends on the sensible and latent energy release of the animals, the thermal properties of the building and the ventilation system and its control unit. For a site in Austria in the north of the Alpine Ridge, which is representative for confined livestock buildings for growing-fattening pigs in Central Europe, meteorological data between 1981 and 2017 were used for the model calculations of heat stress measures. This business-as-usual simulation over these 37 years resulted in an increase of the mean relative annual heat stress parameters in the range between 0.9 and 6.4% per year since 1981. In order to minimise the negative economic impact as the consequence of this positive trend of heat stress, adaptation measures are needed. The calculations for growing-fattening pigs show that such a simulation model for the indoor climate is an appropriate tool to determine the level of heat stress of livestock inside confined livestock buildings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The impact of global warming on livestock husbandry has already been a challenge in the last decades and is a threat for the future. So far, only a few investigations have been undertaken regarding intensive pig and poultry production in confined housing systems, while most of the investigations were performed for grassing animals. This is driven by the fact that grazing animals are immediately impacted by outdoor climate, while confined livestock is kept under artificial climate conditions thought to be less vulnerable to global warming. The majority of pigs and poultry in mid-latitudes are kept in confined livestock buildings (Robinson et al. 2011); at the global level, it is more than half (Niamir-Fuller 2016). Nevertheless, the ability of livestock to tolerate heat stress declines with increasing performance levels, i.e. milk yield in dairy cows, growth rates and proportion of lean meat in pigs or poultry (Dikmen and Hansen 2009; Zumbach et al. 2008; Hoffmann 2013). In pig production, heat stress has been reported to reduce profitability (St-Pierre et al. 2003) but also affects the welfare of the animals (Huynh et al. 2005).

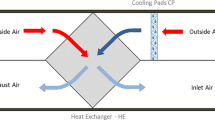

Confined livestock buildings are predominantly mechanically ventilated in Europe. Depending on the season, the mechanical ventilation system fulfils two major goals: (1) to provide sufficient air quality during the cold winter season while still maintaining inside air temperature close to the thermo-neutral zone of the animals and (2) to remove the sensible heat of the animals with high ventilation rates to avoid high indoor air temperatures during the summer season.

The optimum environmental temperature for pigs and poultry lies considerably above the annual outdoor mean temperature, which is ~ 5 °C in Northern Europe (about 60° N) and ~ 15 °C in Southern Europe (about 40° N). The current design of the buildings and the ventilation systems is aligned predominantly to guarantee the lower limit of the thermal neutral zone of the animals (Vitt et al. 2017). Therefore, they are frequently termed warm confinement livestock buildings (Zulovich 1993; Gillespie and Flanders 2009). The geographic distribution of pig density in Europe and the climate classification according to Köppen-Geiger (e.g. Kottek et al. (2006)) shows the highest animal density (Robinson et al. 2014; Robinson et al. 2011) and farm density (Marquer 2010) for the climate classification Cfb temperate oceanic climate (warm temperature, fully humid, warm summers) (Beck et al. 2005). This agreement between climate and animal density can be found for North America and Asia (predominantly China) as well.

The impact of global warming cannot be derived directly from meteorological data as is the case for grazing animals because the indoor climate of buildings differs to quite an extent from the outside situation. Besides the outdoor climate, the thermal environment inside the building depends on the animals as a source of sensible and latent heat and CO2, the thermal properties of the building and the ventilation system and its control unit. Due to this complexity, the use of simulation models is favoured to evaluate and manage the indoor climate. Most of them are based on steady-state sensible and latent heat balances (CIGR 1984; Albright 1990; CIGR 1992, 2002; Blanes and Pedersen 2005; Liberati and Zappavigna 2007; Pedersen et al. 2008; Schauberger et al. 2014). However, the complexities of such models vary with the goal of the models (Fournel et al. 2017), e.g. design applications (DIN 18910; CIGR 2002), the simulation of the indoor climate in a diagnostic mode (Turnpenny et al. 2001; Schauberger et al. 2000) and the impact on airborne emissions (Schauberger et al. 2018). Most of these models are based on the assumption that the inside volume of the livestock building is a box with a spatial homogeneity of the parameters. By the use of computational fluid dynamic models, the spatial structures of various parameters can also be calculated (e.g. Lee et al. 2007; Bjerg et al. 2013). The last group of models cannot be used for long-lasting calculations over 1 year or longer due to the high demand for computing power.

For this investigation, we selected a steady-state simulation model (Schauberger et al. 2000). The model calculations were performed for a typical livestock building for growing-fattening pigs in Central Europe for 1800 heads, divided into nine sections with 200 animals each. Using such a reference building, the transferability of the results to other countries can be achieved. The model calculation was performed for meteorological data on an hourly basis between 1981 and 2017. The location of the meteorological dataset is in the northeast of the Alpine Ridge in Austria in the climate zone Cfb. On the basis of such model calculations, the multi-decadal temporal trend of the thermal climate inside the livestock building can be used as an indicator for future global warming impacts.

The goal of the paper is to estimate the impact of global warming on the thermal conditions inside confined livestock buildings for growing-fattening pigs. By the use of several heat stress measures for pigs, the temporal trend will be investigated in comparison to the outdoor situation. The results will give an orientation whether adaptation measures should be applied to reduce heat stress for growing-fattening pigs in the future.

Materials and methods

Meteorological data

For the calculation of the indoor air conditions, air temperature and relative humidity, meteorological data are needed on an hourly basis. The Austrian Meteorological Service ZAMG (Zentralanstalt für Meteorologie und Geodynamik) compiled a climatic reference scenario on the basis of representative observational sites around the city of Wels (48.16° N, 14.07° E) for the time period 1981 to 2017 with a temporal resolution of 1 h. Following the climate classification of Köppen and Geiger (c.f. Kottek et al. 2006), the station is located within class Cfb temperate oceanic climate which is representative for large areas in Central Europe excluding the Alps. For the whole area of Upper Austria, in the future, a mean increase of temperature is expected with values of ~ + 1.4 °C (~ ± 0.5°) until the middle of the century. The number of hot days (daily maximum temperature ≥ 30 °C) is expected to increase in this region from a mean value of 3.3 hot days/year in the reference period 1971–2000 to between 4.7 and 5.0 days/year in the middle of the century (Chimani et al. 2016). The relationship between air temperature and humidity for this site can be seen by a Mollier diagram (Fig. 1).

Air temperature T and vapour pressure p for outdoor (inlet air, blue) and indoor (red) in 2003 as hourly data, depicted in a Mollier diagram (a rotated psychrometric chart). The relative humidity is shown by the series of curves in 10% steps. The indoor values are calculated for a constant body mass of fattening pigs of m = 105 kg. The selected thresholds for the four heat stress parameters are depicted as coloured lines (temperature XT = 25 °C, specific enthalpy XH = 55 kJ kg−1, temperature-humidity index XTHI = 75 and the controllable temperature range XTL = ΤC and XTU = ΤC + ΔΤP)

Simulation of the indoor climate

The indoor climate was simulated by a steady-state model which calculates the thermal indoor parameters (air temperature, humidity) and the ventilation flow rate. The thermal environment inside the building depends on the livestock, the thermal properties of the building and the ventilation system and its control unit. The core of the model can be reduced to the sensible heat balance of a livestock building (Schauberger et al. 2001, 2000, 1999). The validation of the simulation model was elaborated for fattening pigs by measurements of Schauberger et al. (1995) and Heber et al. (2001).

The model calculations were performed for a typical livestock building for fattening pigs in Central Europe for 1800 heads, divided into nine sections with 200 animals each. The system parameters, which describe the reference building (properties of the livestock, building and the mechanical ventilation system), are summarised in Table 1.

To adapt the control unit to the needs of the animals during the growing-fattening period, the set point temperature ΤC is modified by the body mass m according to

with the set point temperature at the beginning of the fattening period ΤC,start = 20 °C which decreases in the course of the fattening period (mstart ≤ m ≤ mend) by ΔΤP = 4 K to ΤC,end = 16 °C.

For an all-in-all out production system AIAO, an animal growth model describes the increase of the release of energy and CO2 by the growing of the animal body mass of the herd. The time course of the body mass of growing-fattening pigs behaves like a sawtooth wave with a period of 118 days (about one third of a year). These growth periods are superimposed and interact with the time course of the outdoor temperature. To create statistically valid results, we calculate the body mass on the basis of a Monte Carlo method, called inverse transform sampling, a useful method for environmental sciences (e.g. Schauberger et al. 2013; Wilks 2011). There are many techniques for generating a random sample which is distributed according to a pre-selected cumulative distribution function (CDF).

We used the Gompertz model with a constant average daily gain of the body mass m (kg) as a function of time t (days). The body mass values at the beginning and end of the growing-fattening period were selected to be mstart = 30 kg for t = 0 days and mend = 120 kg for tA = 108 days. The duration between two consecutive production cycles, when cleaning and disinfection is performed in the livestock building, is assumed as tS = 10 days. Hence, the overall duration of a growing-fattening period is given by tFP = tA + tS which results in tFP = 108 days + 10 days with a duration of tFP = 118 days, i.e. about 17 weeks.

The inverse sampling technique uses a pseudo-random number RN from a uniform distribution in the interval [0, 1], which is transformed to define the time of the growing-fattening period t in the interval [0 d; 118 d]. The body mass mt (kg) is then calculated by the Gompertz model according to

with the maximum body mass mmax = 208.6 kg, the exponent bm = 1.939 and the growing factor Km = 0.001168 days−1.

Heat stress measures for growing-fattening pigs

Heat stress for pigs can be quantified by the following parameters and related threshold values (Vitt et al. 2017): (1) air temperature (dry bulb) T, (2) temperature-humidity index (THI) and (3) specific enthalpy H, which is equivalent to the apparent equivalent temperature (Mitchell and Kettlewell 1998). For all these parameters, a related threshold value X has to be defined (Table 2). To adapt the heat stress measure to the growth of the pigs between 30 and 120 kg, the exceedance of the controllable temperature range was used with the lower limit XTL = ΤC between 16 and 20 °C as a linear function of the body mass m and the upper limit with XTU = ΤC + ΔΤC. At these two thresholds, the minimum and the maximum ventilation flow rate in relation to the body mass is transported by the ventilation system. The last heat stress measure XTU is defined according to Turnpenny et al. (2001).

For a time series with the length t and n equidistant observations of a selected parameter x, the exceedance frequency PX = prob{x| x > X} can be defined, given in hours per year (h a−1). The second one describes the exceedance area (area under the curve) AX was calculated according to Thiers and Peuportier (2008) by

The area above the threshold X is defined analogously to the degree days (Gosling et al. 2013), but with the selected parameter x used on an hourly basis instead of daily mean values. All measures describing heat stress for pigs are calculated as annual sums over the 37-year period (1981–2017).

Model calculations

The model calculations were performed for the entire growing-fattening period for a body mass between 30 and 120 kg. The calculations were done for 1981 to 2017 to determine the trend for the 37-year period. Additionally, we selected the years 1984 and 2003, as one of the coldest and warmest years, respectively, for summertime measured in the last decades, to show specific results outside of the trend calculations. The trend is estimated with a linear function xtrend = b x + a for the period 1981 to 2017. The starting point of the linear trend is calculated for 1981 as a reference value.

Results and discussion

The results of the simulation of the indoor climate are presented for the hygrothermal parameters (heat stress), the air quality (via the CO2 concentration), the ventilation volume and the related electrical energy demand. In combination with threshold values X for these parameters, the exceedance frequency PX, given as an annual mean value (h/a), and the exceedance area AX, which can be interpreted as the area under the curve, are presented. Using these parameters, the results are focused predominantly on the occurrence of heat stress, whereas cold stress is mostly omitted (Table 3). The exceedance frequency PX (Turnpenny et al. 2001; Haskell et al. 2011) and the exceedance area AX (St-Pierre et al. 2003; Thiers and Peuportier 2008; Gosling et al. 2013) are used widely as measures for heat stress.

The model calculations of the indoor climate were performed for a dataset of more than three decades between 1981 and 2017. The length of the dataset has the advantage that the results are not sensitive to erratic artefacts. Further on, the length gives the opportunity to calculate trends over more than three decades which is unfeasible for shorter datasets as it was performed by St-Pierre et al. (2003). They generated synthetic data, which are not able to include extreme weather episodes like heat waves (e.g. for the year 2013). The distribution of air temperature T and vapour pressure p is shown in Fig. 1 for outdoor (inlet air) and indoor situations for 2003. The occurrence of heat stress is shown by the selected heat stress measures and the related thresholds X (Table 2). The exceedance frequency PX is determined by the number of data points (hourly values) above the related threshold line Xi. The exceedance area AX is given by the sum of the distances of these data points and the threshold line.

The time course of the calculated parameters is shown in Fig. 2a for the exceedance frequency PX and in Fig. 2b for the exceedance area AX. The outdoor and the corresponding indoor parameters are shown in the same colour with different brightness. The temporal trend is assessed by a linear regression over the 37 years. The expected heat stress in the near future can be assessed by a short time extrapolation. Comparing the mean annual trend of the observed heat stress measures outdoor and indoor, the vulnerability of traditional livestock buildings can be determined (Table 3).

The shift of all the outside parameters for heat stress to higher values inside is caused by the sensible and latent heat production of the animals. Two outstanding years are accentuated by light blue for the cold year 1984 and light red for 2003 as a hot year in this period. According to Schär et al. (2004), the summer of 2003 was statistically extremely unlikely at its time, but it can be used as a typical warm year for the middle of the twenty-first century. The cold year of 1984 shows the highest frequency of minimum values for heat stress (6 of 8) as well as the hot year of 2003 with 6 of 8 maximum values.

The mean linear trend of the exceedance parameters PX and AX is positive for all heat stress measures (exceedance of the threshold values XT, XH, XTHI and XTU), showing a mean relative annual change for the indoor climate of about 0.9% (PTU) to 3.0% (PTHI) per year for the exceedance frequency PX and 1.5% (ATU) to 6.4% (ATHI) for the exceedance area AX. The lowest values are found for the temperature threshold XTU and the highest values for XTHI with more than a tripled relative trend. This shows that the heat stress is not only caused by the temperature increase but is also due to the increase of the humidity inside the livestock building. Even if stationarity cannot be assumed for global warming (Hendry and Pretis 2016), the trend can be used as an educated guess for the near future.

The exceedance frequency of the upper limit of the controllable range PTU was calculated between PTU = 921 h/a (minimum in 1984) and PTU = 1747 h/a (maximum in 2003). Turnpenny et al. (2001) found for 1997 a value of PTU = 1018 h/a, calculated for Southeast England.

The slope of the linear annual temporal trend is distinctly steeper for the indoor values as compared to the outside situation. The increase lies in the range of 28 to 70% for PX and 75 to 162% for AX. Therefore, the indoor climate is more vulnerable for global warming than the outdoor situation. This means that the direct use of meteorological data—i.e. without the use of a simulation model for the indoor climate—underestimates the likelihood of the occurrence of heat stress in animals inside confined livestock buildings.

The fact that the relative increase of heat stress shows higher values as the reduction of cold stress shows that global warming will result not only in a shift of the mean value but also in an increase of the variability of thermal parameters (Klein Tank and Können 2003).

Indoor CO2 is mainly selected as a key parameter to evaluate the indoor air quality in relation to animals (CIGR 1984; DIN 18910). Therefore, the maximum recommended CO2 concentration of 3000 ppm is used as a criterion for poor air quality instead of 5000 ppm as the threshold for a human workspace. The exceedance frequency of this threshold (XCO = 3000 ppm) is decreasing from about PCO2 = 283 h/a for 1981 by about − 1.4% per year. The mean indoor air quality is getting better over the years due to the increase of the ventilation flow rate V by about 0.24% per year which is caused by the reduction of the cold stress in the range for PTL by − 0.7%/a and for ATL by − 1.2%/a (Fig. 2).

The specific energy demand of fans depends not only on the fan itself but also on the resistance of the entire ventilation system (e.g. ducts, restrictions). Typical values are in the range between 35 and 66 W per 1000 m3/h (Büscher 2011). We used a value of 47 W per 1000 m3/h. The energy demand of the ventilation system was determined as 16 kWh/a per animal place for the reference year 1981 (Table 3) which is a typical value for growing-fattening pigs (Krommweh et al. 2014; Schmitt-Pauksztat et al. 2006; Lammers et al. 2010; Turnpenny et al. 2001). The mean relative change lies in the range of about 0.24% per year due to the increase in the annual ventilation volume. Turnpenny et al. (2001) found a relative increase of 0.9% per year for the energy demand between 1997 and 2015 (baseline scenario IS92a of the IPCC (1992)).

To manage the distinct temporal trend of the heat stress parameters, adaptive measures have to be applied in the future. The management of livestock offers a wide range of control measures which shall allow for adaptation, such as feeding strategies (Le Bellego et al. 2002; Renaudeau et al. 2012), adaptation of the animal density (reduction of the slaughter live mass and/or the number of animals), measures to increase the heat release of animals (evaporation (Hoff 2013), increased air velocity, cooling of drinking water (Huynh et al. 2006), floor cooling (Wagenberg et al. 2006; Huynh et al. 2004)), modification of the design values when planning livestock buildings (maximum and minimum ventilation flow rate, insulation of the building (Åby et al. 2014)), inverting the diurnal pattern (resting during daytime, feeding during night time) and selecting more adapted genotypes. Certain adaptation measures are part of the ventilation system. These can include energy-saving devices for cooling of the inlet air in order to concomitantly reduce running costs (Vitt et al. 2017). Some measures are applied inside the building, like evaporative cooling (high-pressure fogging (Haeussermann et al. 2007b; Haeussermann et al. 2007a) or evaporative cooling pads (Valiño et al. 2010)). While these measures are likely effective to reduce biomass growth losses and to increase animal welfare under global warming, they will increase production costs in most cases. An assessment of costs and benefits of adaptation shall be subject to further research. It needs to tackle both gains—during the cold season such as for air quality shown in this study—and losses from biomass growth and adaptation during the hot summer season (cf. Mader et al. 2009). The calculated heat stress effects show an essential impact on the performance, health and welfare status of livestock. As stated by Parsons et al. (2000), it is difficult to find suitable experimental data to derive models to quantify the performance depression.

Long-term (seasonal) climate forecasts would be essential for decision-making tools aiming at the mitigation of heat stress for livestock inside confined buildings. Such seasonal climate forecasts for agricultural producers are well established (Klemm and McPherson 2017), but the special needs of livestock keeping are not considered yet, particularly for confined livestock buildings.

Conclusions

The simulation of the indoor climate of confined livestock buildings shows a lower resilience for global warming compared to the outside situation. The mean relative annual trend for heat stress parameters between 1981 and 2017 lies in the range between 0.9 and 6.4% per year, relative to the year 1981. The more frequently and more distinctly occurring heat stress situations have an essential influence on the performance, health and welfare status of livestock. Future impacts of global warming will be even more severe. To reduce animal health and welfare problems as well as the economic impact of these changes, appropriate adaptation measures are needed. The selection has to focus on adaptation measures with low investment and operating costs. Long-term (seasonal) climate forecasts similar to those offered for crop producers would be essential for decision-making tools aiming at mitigating heat stress for livestock inside confined buildings. The calculations for growing-fattening pigs show that such a simulation model for the indoor climate of confined livestock buildings is an appropriate tool to determine conditions of heat stress for livestock.

Abbreviations

- m :

-

body mass of the pigs (kg)

- m start :

-

body mass at the beginning of the fattening period (kg)

- m end :

-

body mass at the end of the fattening period (kg)

- U :

-

mean thermal transmission coefficient of walls and ceiling (W m−2 K−1)

- Τ c :

-

set point temperature of the ventilation control unit (°C)

- ΔΤ P :

-

proportional range (bandwidth) of the control unit (K)

- V min :

-

minimum volume flow rate of the ventilation system (m3 h−1)

- V max :

-

maximum volume flow rate of the ventilation system (m3 h−1)

- Τ C,start :

-

set point temperature at the beginning of the fattening period

- t A :

-

duration of the fattening period (days)

- t S :

-

duration between two consecutive production cycles (days)

- t FP :

-

overall duration of a growing-fattening period (days)

- b m :

-

exponent of the Gompertz model (−)

- K m :

-

growing factor of the Gompertz model (days−1)

- T :

-

air temperature (°C)

- THI:

-

temperature-humidity index (−)

- H :

-

specific enthalpy (kJ kg−1)

- T TU :

-

upper temperature limits for the controllable range (°C)

- T TL :

-

lower temperature limits for the controllable range (°C)

- X T :

-

threshold value for air temperature T (°C)

- X H :

-

threshold value for specific enthalpy H (kJ kg−1)

- X THI :

-

threshold value for temperature-humidity index THI (−)

- X CO2 :

-

threshold value for CO2 concentrations THI (−)

- P X :

-

exceedance frequency for a certain threshold X (h/a)

- A X :

-

exceedance area for a certain threshold X

- V :

-

ventilation rate per year (103 m3 a−1)

- E :

-

energy demand per year (kWh a−1)

References

Åby B, Kantanen J, Aass L, Meuwissen T (2014) Current status of livestock production in the Nordic countries and future challenges with a changing climate and human population growth. Acta Agric Scand Sect A Anim Sci 64:73–97

Albright LD (1990) Environment control for animals and plants. American Society of Agricultural Engineers, St Joseph, Michigan

Beck C, Grieser J, Kottek M, Rubel F, Rudolf B (2005) Characterizing global climate change by means of Köppen climate classification. Klimastatusbericht 51:139–149

Bjerg B, Cascone G, Lee IB, Bartzanas T, Norton T, Hong SW, Seo IH, Banhazi T, Liberati P, Marucci A, Zhang G (2013) Modelling of ammonia emissions from naturally ventilated livestock buildings. Part 3: CFD modelling. Biosyst Eng 116(3):259–275. https://doi.org/10.1016/j.biosystemseng.2013.06.012

Blanes V, Pedersen S (2005) Ventilation flow in pig houses measured and calculated by carbon dioxide, moisture and heat balance equations. Biosyst Eng 92(4):483–493

Büscher W (2011) Abluftführung in der Schweine-und Geflügelhaltung im Hinblick auf die Anrainersituation–Stand der Technik. Proceedings of the Bautagung Raumberg-Gumpenstein 2011. Lehrund Forschungungszentrum für Landwirtschaft, Raumberg-Gumpenstein, Austria, pp. 63–68

Chimani B, Heinrich G, Hofstätter M, Kerschbaumer M, Kienberger S, Leuprecht A, Lexer A, Peßenteiner S, Poetsch MS, Salzmann M, Spiekermann R, Switanek M, Truhetz H (2016) ÖKS15 - Klimaszenarien für Österreich. Daten, Methoden und Klimaanalyse, Report, Vienna.

CIGR (1984) Climatization of animal houses. Commission International du Genié Rural, Scottish Farm buildings Investigation Unit, Aberdeen, Scottland

CIGR (1992) Climatization of animal houses. 2nd Report. Commission International du Genié Rural, Centre for Climatization of Animal Houses Advisory Services, Faculty of Agricultural Sciences, State University of Ghent, Ghent

CIGR (2002) Climatization of Animal Houses. Heat and moisture production at animal and house levels. In: Pedersen S, Sällvik K (eds) International Commission of Agricultural Engineering, Section II. Research Centre Bygholm, Danish Institute of Agricultural Sciences, Horsens

Dikmen S, Hansen P (2009) Is the temperature-humidity index the best indicator of heat stress in lactating dairy cows in a subtropical environment? J Dairy Sci 92(1):109–116

DIN 18910 (2017) Thermal insulation for closed livestock buildings – Thermal insulation and ventilation – principles for planning and design for closed ventilated livestock buildings. In: Deutsches Institut für Normung (ed) Beuth, Berlin, p 43

Fournel S, Rousseau AN, Laberge B (2017) Rethinking environment control strategy of confined animal housing systems through precision livestock farming. Biosyst Eng 155(Supplement C):96–123. https://doi.org/10.1016/j.biosystemseng.2016.12.005

Gillespie J, Flanders F (2009) Modern livestock and poultry production. 9th edn. Cengage Learning

Gosling SN, Bryce EK, Dixon PG, Gabriel KMA, Gosling EY, Hanes JM, Hondula DM, Liang L, Bustos Mac Lean PA, Muthers S, Nascimento ST, Petralli M, Vanos JK, Wanka ER (2013) A glossary for biometeorology. Int J Biometeorol 58:1–32. https://doi.org/10.1007/s00484-013-0729-9

Haeussermann A, Hartung E, Jungbluth T, Vranken E, Aerts JM, Berckmans D (2007a) Cooling effects and evaporation characteristics of fogging systems in an experimental piggery. Biosyst Eng 97(3):395–405

Haeussermann A, Vranken E, Aerts JM, Hartung E, Jungbluth T, Berckmans D (2007b) Evaluation of control strategies for fogging systems in pig facilities. Trans ASABE 50(1):265–274

Haskell M, Kettlewell P, McCloskey E, Wall E, Fox N, Mitchell M (2011) Animal welfare and climate change: impacts, adaptations, mitigation and risks. In: Scottish agricultural college. SAC, Edinburgh

Heber AJ, Ni JQ, Haymore BL, Duggirala RK, Keener KM (2001) Air quality and emission measurement methodology at swine finishing buildings. Trans ASAE 44(6):1765–1778

Hendry DF, Pretis F (2016) All change! The implications of non-stationarity for empirical modelling, Forecasting and policy, Oxford Martin School Policy Paper Series, Forthcoming. Available at SSRN: https://ssrn.com/abstract=2898761. Accessed 13 Dec 2018

Hoff S (2013) 11. The impact of ventilation and thermal environment on animal health, welfare and performance. In: Aland AB, Thomas (ed) Livestock housing: modern management to ensure optimal health and welfare of farm animals, vol 1. Wageningen academic publishers, Wageningen, Netherlands, p 209

Hoffmann I (2013) Adaptation to climate change - exploring the potential of locally adapted breeds. Animal 7(Suppl 2):346–362. https://doi.org/10.1017/S1751731113000815

Huynh TTT, Aarnink AJA, Gerrits WJJ, Heetkamp MJH, Canh TT, Spoolder HAM, Kemp B, Verstegen MWA (2005) Thermal behaviour of growing pigs in response to high temperature and humidity. Appl Anim Behav Sci 91:1–2):1-16. https://doi.org/10.1016/j.applanim.2004.10.020

Huynh TTT, Aarnink AJA, Spoolder HAM, Verstegen MWA, Kemp B (2004) Effects of floor cooling during high ambient temperatures on the lying behavior and productivity of growing finishing pigs. Trans Am Soc Agric Eng 47(5):1773–1782

Huynh TTT, Aarnink AJA, Truong CT, Kemp B, Verstegen MWA (2006) Effects of tropical climate and water cooling methods on growing pigs' responses. Livest Sci 104(3):278–291. https://doi.org/10.1016/j.livsci.2006.04.029

IPCC (1992) Climate change 1992: the supplementary report to the IPCC scientific assessment. Intergovernmental Panel on Climate Change, Cambridge University Press, New York,

Klein Tank AMG, Können GP (2003) Trends in indices of daily temperature and precipitation extremes in Europe, 1946-99. J Clim 16(22):3665–3680. https://doi.org/10.1175/1520-0442(2003)016<3665:TIIODT>2.0.CO;2

Klemm T, McPherson RA (2017) The development of seasonal climate forecasting for agricultural producers. Agric For Meteorol 232:384–399. https://doi.org/10.1016/j.agrformet.2016.09.005

Kottek M, Grieser J, Beck C, Rudolf B, Rubel F (2006) World map of the Köppen-Geiger climate classification updated. Meteorol Z 15(3):259–263

Krommweh MS, Rösmann P, Büscher W (2014) Investigation of heating and cooling potential of a modular housing system for fattening pigs with integrated geothermal heat exchanger. Biosyst Eng 121(0):118–129. https://doi.org/10.1016/j.biosystemseng.2014.02.008

Lammers P, Honeyman M, Harmon J, Helmers M (2010) Energy and carbon inventory of Iowa swine production facilities. Agric Syst 103(8):551–561

Le Bellego L, Van Milgen J, Noblet J (2002) Effect of high temperature and low-protein diets on the performance of growing-finishing pigs. J Anim Sci 80(3):691–701

Lee IB, Sase S, Sung SH (2007) Evaluation of CFD accuracy for the ventilation study of a naturally ventilated broiler house. Jpn Agric Res Q 41(1):53–64

Liberati P, Zappavigna P (2007) A dynamic computer model for optimization of the internal climate in swine housing design. Trans ASABE 50(6):2179–2188

Mader TL, Frank KL, Harrington JAJ, Hahn GL, Nienaber JA (2009) Potential climate change effects on warm-season livestock production in the Great Plains. Clim Chang 97(3–4):529–541. https://doi.org/10.1007/s10584-009-9615-1

Marquer P (2010) Pig farming in the EU, a changing sector. Statistics in focus Eurostat 1–12

Mitchell MA, Kettlewell PJ (1998) Physiological stress and welfare of broiler chickens in transit: solutions not problems! Poult Sci 77(12):1803–1814

Niamir-Fuller M (2016) Towards sustainability in the extensive and intensive livestock sectors. OIE Rev Sci Tech 35(2):371–387. https://doi.org/10.20506/rst.35.2.2531

Parsons DJ, Armstrong AC, Turnpenny JR, Matthews AM, Cooper K, Clark JA (2001) Integrated models of livestock systems for climate change studies. 1. Grazing systems. Glob Chang Biol 7:93-112

Pedersen S, Blanes-Vidal V, Jørgensen H, Chwalibog A, Haeussermann A, Heetkamp M, Aarnink A (2008) Carbon dioxide production in animal houses: a literature review. Agricultural Engineering International: CIGR Journal

Renaudeau D, Collin A, Yahav S, De Basilio V, Gourdine JL, Collier RJ (2012) Adaptation to hot climate and strategies to alleviate heat stress in livestock production. Animal 6(5):707–728. https://doi.org/10.1017/S1751731111002448

Robinson T, Thornton P, Franceschini G, Kruska R, Chiozza F, Notenbaert A, Cecchi G, Herrero M, Epprecht M, Fritz S (2011) Global livestock production systems. Food and Agriculture Organization of the United Nations (FAO),a

Robinson TP, Wint GRW, Conchedda G, Van Boeckel TP, Ercoli V, Palamara E, Cinardi G, D'Aietti L, Hay SI, Gilbert M (2014) Mapping the global distribution of livestock. PLoS One 9(5):e96084. https://doi.org/10.1371/journal.pone.0096084

Schär C, Vidale PL, Lüthi D, Frei C, Häberli C, Liniger MA, Appenzeller C (2004) The role of increasing temperature variability in European summer heatwaves. Nature 427(6972):332–336

Schauberger G, Große Beilage E, Große Beilage T, Pilati P, Rubel F (1995) Stallklimaüberwachung- ein Beitrag zur Bestandsbetreuung (Monitoring of the indoor climate in animal houses as part of herd management). Wiener Tierarztliche Monatsschrift 82(10):299–308

Schauberger G, Piringer M, Baumann-Stanzer K, Knauder W, Petz E (2013) Use of a Monte Carlo technique to complete a fragmented set of H2S emission rates from a waste water treatment plant. J Hazard Mater 263:694–701

Schauberger G, Piringer M, Heber AJ (2014) Odour emission scenarios for fattening pigs as input for dispersion models: a step from an annual mean value to time series. Agric Ecosyst Environ 193:108–116. https://doi.org/10.1016/j.agee.2014.04.030

Schauberger G, Piringer M, Mikovits C, Zollitsch W, Hörtenhuber SJ, Baumgartner J, Niebuhr K, Anders I, Andre K, Hennig-Pauka I, Schönhart M (2018) Impact of global warming on the odour and ammonia emissions of livestock buildings used for fattening pigs. Biosyst Eng 175:106–114. https://doi.org/10.1016/j.biosystemseng.2018.09.001

Schauberger G, Piringer M, Petz E (1999) Diurnal and annual variation of odour emission from animal houses: a model calculation for fattening pigs. J Agric Eng Res 74(3):251–259

Schauberger G, Piringer M, Petz E (2000) Steady-state balance model to calculate the indoor climate of livestock buildings demonstrated for fattening pigs. Int J Biometeorol 43(4):154–162

Schauberger G, Piringer M, Petz E (2001) Separation distance to avoid odour nuisance due to livestock calculated by the Austrian odour dispersion model (AODM). Agric Ecosyst Environ 87(1):13–28

Schmitt-Pauksztat G, Buscher W, Kamper H (2006) Planungsdaten zum Elektroenergie-Verbrauch in der Schweinehaltung. In: KTBL (ed) Energieversorgung in Geflügel- und Schweineställen, vol 445. Kuratorium für Technik und Bauwesen in der Landwirtschaft e. V. (KTBL), Darmstadt, Germany, pp 43–52

St-Pierre NR, Cobanov B, Schnitkey G (2003) Economic losses from heat stress by US livestock industries. J Dairy Sci 86:E52–E77. https://doi.org/10.3168/jds.S0022-0302(03)74040-5

Thiers S, Peuportier B (2008) Thermal and environmental assessment of a passive building equipped with an earth-to-air heat exchanger in France. Sol Energy 82(9):820–831. https://doi.org/10.1016/j.solener.2008.02.014

Turnpenny JR, Parsons DJ, Armstrong AC, Clark JA, Cooper K, Matthews AM (2001) Integrated models of livestock systems for climate change studies. 2. Intensive systems. Glob Chang Biol 7(2):163–170

Valiño V, Perdigones A, Iglesias A, García JL (2010) Effect of temperature increase on cooling systems in livestock farms. Clim Res 44(1):107–114

Vitt R, Weber L, Zollitsch W, Hörtenhuber SJ, Baumgartner J, Niebuhr K, Piringer M, Anders I, Andre K, Hennig-Pauka I, Schönhart M, Schauberger G (2017) Modelled performance of energy saving air treatment devices to mitigate heat stress for confined livestock buildings in Central Europe. Biosyst Eng 164:85–97

Wagenberg AV, Peet-Schwering CMC, Binnendijk GP, Claessen PJPW (2006) Effect of floor cooling on farrowing sow and litter performance: field experiment under Dutch conditions. Trans ASABE 49(5):1521–1527. https://doi.org/10.13031/2013.22044

Wilks DS (2011) Statistical methods in the atmospheric sciences, vol 100. International Geophysics Series. Academic press, San Diego, CA

Zulovich JM (1993) Ventilation for warm confinement livestock buildings. Extension publications G1107. University of Missouri, Columbia

Zumbach B, Misztal I, Tsuruta S, Sanchez JP, Azain M, Herring W, Holl J, Long T, Culbertson M (2008) Genetic components of heat stress in finishing pigs: development of a heat load function. J Anim Sci 86(9):2082–2088. https://doi.org/10.2527/jas.2007-0523

Acknowledgements

Open access funding provided by University of Veterinary Medicine Vienna. The project PiPoCooL Climate change and future pig and poultry production: implications for animal health, welfare, performance, environment and economic consequences was funded by the Austrian Climate and Energy Fund within the frame work of the Austrian Climate Research Program (ACRP8—PiPoCooL—KR15AC8K12646).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mikovits, C., Zollitsch, W., Hörtenhuber, S.J. et al. Impacts of global warming on confined livestock systems for growing-fattening pigs: simulation of heat stress for 1981 to 2017 in Central Europe. Int J Biometeorol 63, 221–230 (2019). https://doi.org/10.1007/s00484-018-01655-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00484-018-01655-0