Abstract

The ultrasonic-assisted drilling (UAD) process is being developed due to its apparent advantages over the conventional drilling (CD) process in terms of thrust force and torque reduction and improvements in surface finish and hole accuracy. However, as with CD, heat generated during UAD might affect tool life, including damage to the cutting edges of the drill. The research reported here has two main objectives: (1) finding the best technique to measure temperatures in UAD, and (2) measure the effect of ultrasonic vibrations in heat generated in UAD. In this paper, two scenarios are used to examine five temperature measurement techniques, these being embedded thermocouples in the material, infrared (IR) sensor, IR camera, and embedding thermocouples in the drill cooling channels and surface thermocouples. It is found that embedding thermocouples in the drill cooling channels is the best and most reliable technique for measuring temperature in UAD. This method is then used to investigate the effects of ultrasonic vibrations on heat generated in UAD of aluminum 6061, alloy steel 4340, and stainless steel 316. The effect of ultrasonic vibrations on thrust force is also studied in this investigation.

Similar content being viewed by others

References

Alam K, Silberschmidt VV (2014) Analysis of temperature in conventional and ultrasonically-assisted drilling of cortical bone with infrared thermography. Technol Health Care 2(22):243–252

Alam K, Hassan E, Bahadur I (2015) Experimental measurements of temperatures in ultrasonically assisted drilling of cortical bone. Biotechnol Biotechnol Equip 4(29):753–757

Shakouri E, Sadeghi MH, Karafi MR, Maerefat M, Farzin M (2015) An in vitro study of thermal necrosis in ultrasonic-assisted drilling of bone. Proc Inst Mech Eng H J Eng Med 2(229):137–149

Gupta A, Barnes, S., McEwen, I., Kourra, N, & Williams, M.A. (2014). Study of cutting speed variation in the ultrasonic assisted drilling of carbon fibre composites. Int Mech Eng Congress Expo, (2B), 160–170. https://doi.org/10.1115/IMECE2014-37046

Pujana J, Rivero A, Celaya A, Lopez De Lacalle LN (2009) Analysis of ultrasonic-assisted drilling of Ti6Al4V. Int J Mach Tool Manu 49:500–508

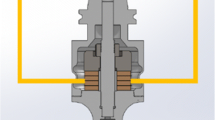

Moghaddas MA, Short MA, Wiley NA, Yi AY, Graff KF (2018) Performance of an ultrasonic-assisted drilling module. Int J Adv Manuf Technol 94:3019–3028

Moghaddas MA, Short MA, Wiley NR, Yi AY, Graff KF (2018) Improving productivity in an ultrasonic-assisted drilling vertical machining center. In: Journal of manufacturing science and engineering, (140)6, vol 140, p 061002

Garr Tool (2016) Catalogue 16-high performance solid carbide cutting tools. 19–71

Acknowledgments

The authors would like to thank Edison Welding Institute (EWI) for providing the funding and equipment for this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moghaddas, M.A., Yi, A.Y. & Graff, K.F. Temperature measurement in the ultrasonic-assisted drilling process. Int J Adv Manuf Technol 103, 187–199 (2019). https://doi.org/10.1007/s00170-019-03487-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03487-7