Abstract

Rheological and mechanical properties of aqueous mono-disperse silica suspensions (Ludox® HS40) are investigated as a function of particle volume fraction (ϕ p ranging from 0.22 to 0.51) and water content, using shear rate tests, oscillatory methods, indentation and an ultrasonic technique. As the samples are progressively dried, four regimes are identified; they are related to the increasing particle content and the existence and behaviour of the electrical double layer (EDL) around each particle. For 0.22 ≤ ϕ p ≤ 0.30), the suspensions are stable due to the strong electrostatic repulsion between particles and show Newtonian behaviour (I). As water is removed, the solution pH decreases and the ionic strength increases. The EDL thickness therefore slowly decreases, and screening of the electrostatic repulsion increases. For 0.31 ≤ ϕ p ≤ 0.35, the suspensions become turbid and exhibit viscoelastic (VE) shear thinning behaviour (II), as they progressively flocculate. For 0.35 ≤ ϕ p ≤ 0.47, the suspensions turn transparent again and paste-like, with VE shear thinning behaviour and high elastic modulus (III). At higher particle concentration, the suspensions undergo a glass transition and behave as an elastic brittle solid (IV, ϕ p = 0.51).

Similar content being viewed by others

References

Ackerson BJ, Pusey PN (1988) Shear-induced order in suspensions of hard-spheres. Phys Rev Lett 61:1033–1036

Allain C, Cloitre M, Lacoste B, Marsone I (1994) Viscosity renormalization in colloidal suspensions. J Chem Phys 100:4537–4542

Aubry T, Largenton B, Moan M (1998) Study of aggregate density in fumed silica suspensions. J Colloid Interface Sci 202:551–553

Ballesta P, Besseling R, Isa L, Petekidis G, Poon WCK (2008) Slip and flow of hard-sphere colloidal glasses. Phys Rev Lett 101:258301

Barnes (1995) A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: its cause, character and cure. J Non-Newton Fluid Mech 56:221–251

Batchelor G (1970) The stress system in a suspension of force-free particles. J Fluid Mech 41:54570

Berli CLA, Deiber JA, Quemada D (2005) On the viscosity of concentrated suspensions of charged colloids. Lat Am Appl Res 35:15–22

Birdi KS (1997) Handbook of surface and colloid chemistry. CRC, Boca Raton

Buscall R, Goodwni JW, Hawkins MW, Ottewill RH (1982) Viscoelastic properties of concentrated latices. J Chem Soc Faraday Trans 1 78:2889–2899

Buscall R (1991) Effect of long-range repulsive forces on the viscosity of concentrated latices: comparison of experimental data with an effective hard-sphere model. J Chem Soc Faraday Trans 1 87:1365–1370

Buscall R, McGowan JI, Morton-Jones AJ (1993) The rheology of concentrated dispersions of weakly-attracting colloidal particles with and without wall slip. J Rheol 37:621–641

Buscall R (2010) Letter to the editor: wall slip in dispersion rheometry. J Rheol 54:1177–1183

Cao XJ, Cummins HZ, Morris JF (2010) Structural and rheological evolution of silica nanoparticle gels. Soft Mater doi:10.1039/c0sm00433b

Channel GM, Zukoski CF (1997) Shear and compressive rheology of aggregated alumina suspensions. AiCHE J 43:1700–1708

Chen H, Ackerson BJ, Zukoski CF (1994) Rheological consequences of microstructural transitions in colloidal crystals. J Rheol 38:193–216

Chen H, Ding Y, Tan C (2007) Rheological behaviour of nanofluids. New J Phys 9:367

Chevalier J, Tillement O, Ayela F (2009) Structure and rheology of SiO2 nanoparticle suspensions under very high shear rate. Phys Rev E 80:051403

Chougnet A, Audibert A, Moan M (2007) Linear and non-linear rheological behaviour of cement and silica suspensions. Effect of polymer addition. Rheol Acta 46:793–802

Dames B, Morrison BR, Willenbacher N (2001) An empirical model predicting the viscosity of highly concentrated, bimodal dispersions with colloidal interactions. Rheol Acta 40:434–440

Dickinson E (1992) An introduction to food colloids. Oxford University Press, New York

Di Cola E, Moussaïd A, Sztucki M, Narayanan T, Zaccarelli E (2009) Correlation between structure and rheology of a model colloidal glass. J Chem Phys 131:144903

Di Giuseppe E, Davaille A (2010) Initiation of subduction in the laboratory from solutal convection in a complex-rheology fluid. Geophys Res Abstr 23:07954

Drabarek E, Bartlett JR, Hanley HJM, Woolfrey JL, Muzny CD, Butler BD (2000) Shear-induced restructuring of colloidal silica gels. J Sol-Gel Sci Technol 19:279–283

Drabarek E, Bartlett JR, Hanley HJM, Woolfrey JL, Muzny CD (2002) Effects of processing variables on the structural evolution of silica gels. Int J Thermophys 23:145–159

Dufresne ER, Corwin EI, Greenblatt NA, Ashmore J, Wang DY, Dinsmore AD, Cheng JX, Xie XS, Hutchinson JW, Weitz DA (2003) Flow and fracture in drying nanoparticle suspensions. Phys Rev Lett 91:224501

Einstein A (1906) Eine neue bestimmung der molekul-dimension. Ann Phys 28:207–227

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Gauthier G, Lazarus V, Pauchard L (2007) Alternating crack propagation during directional drying. Langmuir 23:4715–4718. doi:10.1021/la063702w

Gauthier G, Lazarus V, Pauchard L (2010) Shrinkage star-shaped cracks: explaining the transition from 90 degrees to 120 degrees. Europhys Lett 89:10.1209/0295–5075/89/26002

Goehring L, Clegg WJ, Routh AF (2010) Solidification and ordering during directional drying of a colloidal dispersion. Langmuir 26:9269–9275

Grant MC, Russel WB (1993) Volume-fraction dependence of elastic moduli and transition temperatures for colloidal silica gels. Phys Rev E 47:2606–2614

Israelachvili JN (1985) Intermolecular and surface forces. Academic, San Diego

Jeffrey DJ, Acrivos A (1976) The rheological properties of suspensions of rigid particles. AIChE J 22:417–432

Jones DQR, Leary B, Boger DV (1991) The rheology of a concentrated colloidal suspension of hard sphere. J Colloid Interface Sci 147:479–495

Krieger IM, Dougherty TJ (1959) A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans Soc Rheol 3:137–152

Larson RG (1999) The structure and rheology of complex fluids. Oxford University Press, New York

Lin MY, Lindsay HM, Weitz DA, Ball RC, Klein R, Meakin P (1989) Universality of colloid aggregation. Nature 339:360–362

Madeline JB, Meireles M, Bourgerette C, Botet R, Schweins R, Cabane B (2007) Restructuring of colloidal cakes during dewatering. Langmuir 23:1645–1658

Malzbender J, Den Toonder JMJ, Balkenende AR, de With G (2002) Measuring mechanical properties of coatings: a methodology applied to nano-particle-filled sol–gel coatings on glass. Mater Sci Eng R 36:47–103

Mason TG, Weitz DA (1995) Linear viscoelasticity of colloidal hard sphere suspensions near the glass transition. Phys Rev Lett 75:2770–2773

Mattsson J, Wyss HM, Fernadez-Nieves A, Miyazaki K, Hu Z, Reichman DR, Weitz DA (2009) Soft colloids make strong glasses. Nature 462:83–86

Meeker SP, Bonnecaze RT, Cloitre M (2004) Slip and flow in soft particle pastes. Phys Rev Lett 92:198302

Mewis J, Frith WJ, Strivens TA, Russel WB (1989) The rheology of suspensions containing polymerically stabilized particles. AIChE J 35:415–422

Mezger TG (2002) The rheology handbook: for users of rotational and oscillatory rheometers. Vincentz Network, Hannover

Olivier OC, Pharr GM (1992) An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–583

Ouglova A, Berthaud Y, Franois M and Foct F (2006) Mechanical properties of an iron oxide formed by corrosion in reinforced concrete structures. Corros Sci 48:3988–4000

Park J, Park SB, Yang SM, Hong WH, Choi CR, Kim JH (2005) Rheological characterization and optimization of gelled electrolyte for sealed lead-acid batteries by small amplitude dynamic oscillation measurement. J Non-Cryst Solids 351:2352–2357

Pauchard L, Parisse F, Allain C (1999) Influence of salt content on crack patterns formed through colloidal suspension desiccation. Phys Rev E 59:3737–3740

Pauchard L (2006) Patterns caused by buckle-driven delamination in desiccated colloidal gels. Europhys Lett 74:188–194

Prasher R, Evans W, Meakin P, Fish J, Phelan P, Keblinski P (2006) Effect of aggregation on thermal conduction in colloidal nanofluids. Appl Phys Lett 89:143119

Quemada D (1977) Rheology of concentrated disperse systems and minimum energy-dissipation principle. 1. Viscosity–concentration relationship. Rheol Acta 16:82–94

Roscoe R (1952) The viscosity of suspensions of rigid spheres. Br J Appl Phys 3:267–269

Royer D, Dieulesaint E (1989) Optical measurements of displacements of amplitude 10–4 to 10–2 angstrom application to elastic-waves. Revue Phys Appl 24:833–846

Rueb CJ, Zukoski CF (1997) Viscoelastic properties of colloidal gels. J Rheol 41:197–217

Russel WB (1978) The rheology of suspensions of charged rigid spheres. J Fluid Mech 85:209–232

Russel WB, Grant MC (2000) Distinguishing between dynamic yielding and wall slip in a weakly flocculated colloidal dispersion. Colloids Surf A 161:271–282

Russel WB (2009) Structure–property relations for the rheology of dispersions of charged colloids. Ind Eng Chem Res 48:2380–2386

Schall P, Cohen I, Weitz DA, Spaepen F (2004) Visualization of dislocation dynamics in colloidal crystals. Science 305:1944–1948

Schneider C, Hanish M, Wedel B, Jusufi A, Ballauff M (2011) Experimental study of electrostatically stabilized colloidal particles: colloid stability and charge reversal. J Colloid Interface Sci 358:62–67

Seth JR, Cloitre M, Bonnecaze RT (2008) Influence of short-range forces on wall-slip in microgel pastes. J Rheol 52:1241–1268

Sherwood JD (1980) The primary electroviscous effect in a suspension of spheres. J Fluid Mech 101:609–629

Shih WH, Shih WY, Kim SI, Liu J, Aksay IA (1990)5 Scaling behavior of the elastic properties of colloidal gels. Phys Rev A 42:4772–4779

Sollich P (1998) Rheological constitutive equation for a model of soft glassy materials. Phys Rev E 58:738–459

Stickel JJ, Powell RL (2005) Fluid mechanics and rheology of dense suspensions. Annu Rev Fluid Mech 37:129–149

Tabor D (1951) Hardness of metals. Oxford Academic, Oxford

Trompette JL, Meireles M (2003) Ion-specific effect on the gelation kinetics of concentrated colloidal silica suspensions. J Colloid Interface Sci 263:522–527

Trompette JL, Clifton MJ (2004) Influence of ionic specificity on the microstructure and the strength of gelled colloid silica suspensions. J Colloid Interface Sci 276:475–482

Tsenoglou C (1990) Scaling concepts in suspension rheology. J Rheol 34:15–23

van de Ven TGM (1989) Colloidal hydrodynamics. Academic, San Diego

Walls et al.(2003) Yield stress and wall slip phenomena in colloidal silica gels. J Rheol 47:847–868

Yanez JA, Laarz E, Bergstrm L (1999) Viscoelastic properties of particle gels. J Colloid Interface Sci 209:162–172

Yang MC, Scriven LE, Macosko CW (1986) Some rheological measurements on magnetic iron oxide suspensions in silicone oil. J Rheol 30:1015–1029

Zarzycki J (1988) Critical stress intensity factors of wet gels. J Non-Cryst Solids 100:359–363

Acknowledgements

This work benefited from discussions with Ludovic Pauchard, Véronique Lazarus, Georges Gauthier, Mourad Chekchaki, Fabien Mahaut, Neil Ribe, John Sherwood, Jérome Martin, Thomas Schweizer and Ching Hsueh. The manuscript was improved thanks to the very thorough comments of three anonymous reviewers. E. Di Giuseppe was funded by a joint fellowship from the Swiss National Science Foundation (Subside nr. PBEXP2-122908) and the French Agence Nationale de la Recherche (PTECTO NT09-604042). Eric Mittelstaedt was supported by the International Research Fellowship Program of the U.S. National Science Foundation (OISE-0757920). The rheometer was supported by the Triangle de la Physique and the indenter by the French Agence Nationale de la Recherche ( “Morphologies” JCJC-05-0029).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: DLVO calculations

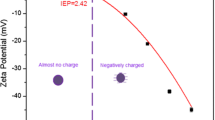

In the DLVO theory of colloidal interactions, the potential U between two identical spherical particles of diameter a and surface separation x is the sum of the attractive van der Waals potential, U vdW, and the electrostatic repulsion potential, U rep, which are written when κa/2 > > 1:

where A = 0.8 × 10 − 20 J is the Hamaker constant for silica in water (e.g. Larson 2002), ϵ is the permittivity of the liquid dispersant, e is the charge of an electron and T = 293 K is the temperature. Figure 9a presents the different contributions and the potential as κ − 1 decreases for our samples. U is characterized by one stable attractive minimum (“p” on Fig. 9a), a metastable secondary minimum (“s”) and a barrier potential in between. Aggregation will occur when the particles fall into “p”.

One important parameter entering Eq. 10 is the surface potential, ψ D. Unfortunately, we were unable to measure it for the different samples. For the Newtonian samples, U has been calculated taking the value ψ D = −30 mV measured at ϕ p = 0.22 by Trompette and Clifton (2004). However, we expect ψ D to vary with the ionic strength; it usually increases with increasing I (e.g. Schneider et al. 2011). For the non-Newtonian samples, the DLVO model allows an estimate of ψ D from the shear modulus (Buscall et al. 1982):

where α = 0.833 and \(R = a(0.74 / \phi_{\rm p})^{1/3}\) for particles arranged in a face-centered cubic lattice. Figure 12 shows the measured shear modulus as a function of the calculated \(G_{\rm o}^{\rm th} / \psi_{\rm D}^2\). Despite the uncertainty on the G o measurements (cf. “Rheological measurements” section), the data points are aligned for 0.32 ≤ ϕ p ≤ 0.38 and the slope gives a value ψ D = −22 mV. This is the value that we took to estimate the interaction potential for the non-Newtonian samples in Fig. 9a.

Experimental limiting shear modulus G o as a function of the theoretical \(G_{\rm o}^{\rm th}/\psi_{\rm D}^2\) (Buscall et al. 1982). The data points are aligned for 0.32 ≤ ϕ p ≤ 0.38, with a slope giving ψ D = −22 mV (labelled 0.0005) and quite different from the 0.0009 slope expected if ψ D = −30 mV. On the other hand, the two very pasty samples (ϕ p > 0.38) do not follow either trends

Appendix 2: Thixotropy

We investigated thixotropy in samples with ϕ p = 0.31 and ϕ p = 0.36, i.e. a sample with fluid VE behaviour and another with solid VE behaviour, respectively. We performed the test under a constant shear load in each single test interval. The sample with ϕ p = 0.31 still displays a very low degree of structural decomposition during the shear phase, and a complete structural regeneration occurs quickly during the rest phase (Fig. 13a). On the contrary, the sample with ϕ p = 0.36 exhibits an irreversible structural change; the initial structural strength is not recovered during the rest phase (Fig. 13b). This may originate from the increasing presence of aggregates in the samples as ϕ p increases and their destruction during the application of shear. The process is irreversible as the samples undergo failure. The difference between the two samples is coherent with the fact that the ϕ p = 0.31 sample is the first one presenting non-Newtonian behaviour (Fig. 3), while the ϕ p = 0.36 is already paste-like.

Thixotropic behaviour determined for a ϕ p = 0.31 and b ϕ p = 0.36. Three intervals are preset for the measurements: the rest phase, Δt 1, under low shear-rate, \(\dot{\gamma}=\) 0.1 s − 1; the load phase, Δt 2, under high shear-rate, \(\dot{\gamma}=\) 1,000 s − 1 and the removing load phase, Δt 3, in which the same conditions of the first phase are applied

Rights and permissions

About this article

Cite this article

Di Giuseppe, E., Davaille, A., Mittelstaedt, E. et al. Rheological and mechanical properties of silica colloids: from Newtonian liquid to brittle behaviour. Rheol Acta 51, 451–465 (2012). https://doi.org/10.1007/s00397-011-0611-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-011-0611-9