Abstract

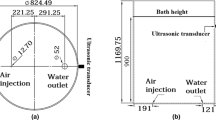

This article reports the results of an investigation of the fluid flow in an agitated quench tank used during heat treatment of superalloy forgings. The flow patterns in a scale model of the system were visualized using a laser light sheet and quantitative velocity measurements were undertaken using laser Doppler anemometry (LDA). The experimental data are compared with numerical predictions obtained by means of a computational fluid dynamics (CFD) computer code. Conclusions are drawn as to the suitability of the CFD code for predicting flows in a complex system of this type.

Similar content being viewed by others

References

R.A. Wallis, P.R. Bhowal, N.M. Bhathena, and E.L. Raymond, Modeling the Heat Treatment of Superalloy Forgings,JOM, Vol 41 (No. 2), Feb 1989, p 35–37

R.A. Wallis, Using Computer Programs to Calculate Heat Transfer,Heat Treating, Vol 21 (No. 12), Dec 1989, p 26, 27, 31

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Garwood, D.R., Lucas, J.D., Wallis, R.A. et al. Modeling of the flow distribution in an oil quench tank. JMEP 1, 781–787 (1992). https://doi.org/10.1007/BF02658261

Issue Date:

DOI: https://doi.org/10.1007/BF02658261