Abstract

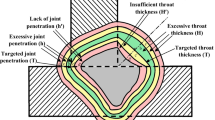

In this paper, a fuzzy pattern recognition technique is applied to classifying aluminium weld quality in tungsten inert gas (TIG) welding. The pattern vector includes three components, that is, the front height, the back height, and the front width of weld. Based on the values of the pattern vector, good, fair, and poor weld qualities can be automatically classified by using the fuzzy pattern recognition technique. Experimental results under different welding parameters are presented to illustrate the proposed method.

Similar content being viewed by others

References

S. T. Bow,Pattern Recognition, Marcel Dekker, New York, 1985.

J. C. Bezdek,Pattern Recognition with Fuzzy Objective Function Algorithms, Plenum Press, New York, 1981.

L. Zadeh, “Fuzzy sets”,Information Control 8, pp. 338–353, 1965.

A. Kandel,Fuzzy Techniques in Pattern Recognition, John Wiley & Sons, New York, 1982.

M. Roubens, “Pattern classification problems and fuzzy sets”,Fuzzy Sets and Systems 1, pp. 239–253, 1978.

T. L. Huntsberger, C. Rangarajan and S. N. Jayaramamurthy, “Representation of uncertainty in computer vision using fuzzy sets”,IEEE Transactions on Computers 35(2), pp. 145–156, 1986.

K. Tanaka and M. Sugeno, “A study on subjective evaluations of printed cloor images”,International Journal of Approximate Reasoning 5(3), pp. 213–222, 1991.

L. Zeng and H. P. Wang, “Machine fault classification: a fuzzy set approach”,International Journal of Advanced Manufacturing Technology 6, pp. 83–94, 1991.

J. K. Tae, D. W. Cho and J. M. Lee, “Fuzzy pattern recognition for tool wear monitoring in diamond turning”,Annals of CIRP 41(1), pp. 125–128, 1992.

H. J. Zimmermann,Fuzzy Set Theory and its Application, Kluwer Academic Publishers, London, 1991.

H. B. Cary,Modern Welding Technology, Prentice Hall, Englewood Cliffs, New Jersey, 1989.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tarng, Y.S., Yeh, S.S. & Juang, S.C. Fuzzy pattern recognition of tungsten inert gas weld quality. Int J Adv Manuf Technol 13, 387–392 (1997). https://doi.org/10.1007/BF01179032

Issue Date:

DOI: https://doi.org/10.1007/BF01179032