ABSTRACT

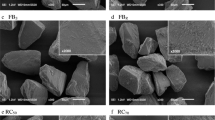

This study investigated the structural relaxation of micronized fluticasone propionate (FP) under different lagering conditions and its influence on aerodynamic particle size distribution (APSD) of binary and tertiary carrier-based dry powder inhaler (DPI) formulations. Micronized FP was lagered under low humidity (LH 25 C, 33% RH [relative humidity]), high humidity (HH 25°C, 75% RH) for 30, 60, and 90 days, respectively, and high temperature (HT 60°C, 44% RH) for 14 days. Physicochemical, surface interfacial properties via cohesive-adhesive balance (CAB) measurements and amorphous disorder levels of the FP samples were characterized. Particle size, surface area, and rugosity suggested minimal morphological changes of the lagered FP samples, with the exception of the 90-day HH (HH90) sample. HH90 FP samples appeared to undergo surface reconstruction with a reduction in surface rugosity. LH and HH lagering reduced the levels of amorphous content over 90-day exposure, which influenced the CAB measurements with lactose monohydrate and salmeterol xinafoate (SX). CAB analysis suggested that LH and HH lagering led to different interfacial interactions with lactose monohydrate but an increasing adhesive affinity with SX. HT lagering led to no detectable levels of the amorphous disorder, resulting in an increase in the adhesive interaction with lactose monohydrate. APSD analysis suggested that the fine particle mass of FP and SX was affected by the lagering of the FP. In conclusion, environmental conditions during the lagering of FP may have a profound effect on physicochemical and interfacial properties as well as product performance of binary and tertiary carrier-based DPI formulations.

Similar content being viewed by others

REFERENCES

Kubavat HA, Shur J, Ruecroft G, Hipkiss D, Price R. Investigation into the influence of primary crystallization conditions on the mechanical properties and secondary processing behaviour of fluticasone propionate for carrier based dry powder inhaler formulations. Pharm Res. 2012;29:994–1006.

Ward GH, Schultz RK. Process-induced crystallinity changes in albuterol sulfate and its effect on powder physical stability. Pharm Res. 1995;12:773–9.

Joshi V, Dwivedi S, Ward GH. Increase in the specific surface area of budesonide during storage postmicronization. Pharm Res. 2002;19:7–12.

Huttenrauch R, Fricke S, Zielke P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985;2:302–6.

Brodka-Pfeiffer K, Langguth P, Grass P, Häusler H. Influence of mechanical activation on the physical stability of salbutamol sulphate. Eur J Pharm Biopharm. 2003;56:393–400.

Shur J, Pitchayajittipong C, Rogueda P, Price R. Effect of processing history on the surface interfacial properties of budesonide in carrier-based dry-powder inhalers. Ther Deliv. 2013;4:925–37.

Wildfong PLD, Hancock BC, Moore MD, Morri KR. Towards an understanding of the structurally based potential for mechanically activated disordering of small molecule organic crystals. J Pharm Sci. 2006;95:2645–56.

Colombo I, Grassi G, Grassi M. Drug mechanochemical activation. J Pharm Sci. 2009;98:3961–86.

Brodka-Pfeiffer K, Häusler H, Grass P, Langguth P. Conditioning following powder micronization: influence on particle growth of salbutamol sulfate. Drug Dev Ind Pharm. 2003;29:1077–84.

Bender H, Graebner H, Schindler K, Trunk M, Watz M.; Boehringer Ingelheim Pharma Gmbh & Co. Kg. Crystalline micronisate, process for the manufacture thereof and use thereof for the preparation of a medicament. US 20040002510 A1. 2004 Jan 1.

Riebe MT, Dwivedi SK, Li-Bovet L.; Smithkline Beecham Corporation. Aerosols containing annealed particulate salbutamol and tetrafluoroethane. US6558651 B1. 2003 May 6.

Muhrer G, Rasenack N.; Novartis AG. Process for reducing the tendency of a glycopyyronium salt to aggregate during storage. EP2234595 B1. 2012 Nov 28.

Begat P, Morton DAV, Staniforth JN, Price R. The cohesive-adhesive balances in dry powder inhaler formulations I: direct quantification by atomic force microscopy. Pharm Res. 2004;21:1591–7.

Pitchayajittipong C, Shur J, Price R. Engineering of crystalline combination inhalation particles of a long-acting beta2-agonist and a corticosteroid. Pharm Res. 2009;26:2657–66.

Shur J, Kaerger JS, Price R. Effect of surface amorphous content of active pharmaceutical ingredients on the performance of dry powder inhaler formulations. RDD Europe 2007; Dalby RN, Byron PR, Peart J, Suman J, editors, Davis Healthcare, Rover Grove, Illinois, Vol 1, pp. 341–4.

Jones MD, Harris H, Hooton JC, Shur J, King GS, Mathoulin CA, et al. An investigation into the relationship between carrier-based dry powder inhalation performance and formulation cohesive-adhesive force balances. Eur J Pharm Biopharm. 2008;69:496–507.

Shur J, Harris H, Jones MD, Kaerger JS, Price R. The role of fines in the modification of the fluidization and dispersion mechanism within dry powder inhaler formulations. Pharm Res. 2008;25:1631–40.

Begat P, Morton DAV, Staniforth JN, Price R. The cohesive-adhesive balances in dry powder inhaler formulations II: influence on fine particle delivery characteristics. Pharm Res. 2004;21:1826–33.

Jones MD, Hooton JC, Dawson ML, Ferrie AR, Price R. An investigation into the dispersion mechanisms of ternary dry powder inhaler formulations by the quantification of interparticulate forces. Pharm Res. 2008;25:337–48.

Rogueda PGA, Price R, Smith T, Young PM, Traini D. Particle synergy and aerosol performance in non-aqueous liquid of two combinations metered dose inhalation formulations: an AFM and Raman investigation. J Colloid Interface Sci. 2011;361:649–55.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Depasquale, R., Lee, S.L., Saluja, B. et al. The Influence of Secondary Processing on the Structural Relaxation Dynamics of Fluticasone Propionate. AAPS PharmSciTech 16, 589–600 (2015). https://doi.org/10.1208/s12249-014-0222-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-014-0222-8