Abstract

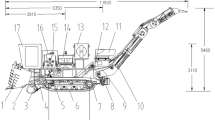

A power operated detrasher was developed for removal of green top as well as dry trash from the harvested sugarcane stalks. It consisted of mechanisms for cane feeding, detrashing and delivery. It separates the top from the cane by breaking it from the natural weak point at the joint of immature top with mature cane stalks. It can be transported on three point linkage of the tractor and operated by an electric motor, diesel engine or tractor PTO. Performance of the equipment was evaluated by feeding different varieties of harvested canes, with their tops first, to the detrashing rollers through the feeding chute. The trash left on the cane after passing through the detrasher varied from 1.5 to 6.6 %. Trash removal efficiency varied from 77.5 to 94.5 % depending upon the variety. The output of the detrasher was 2.4 t/h. There was a saving of about 17 % in cost of operation and 84 % in labour requirement using the detrasher as compared to manual method.

Similar content being viewed by others

References

Anon, 1979. Guide for estimating cost of farm machinery operation (IS: 9164–1979). New Delhi: Indian Standard Institution.

Anon, 2013. Statement showing figures of area under sugarcane, yield of sugarcane, production of sugarcane, number of factories, working capacity, cane crushed, recovery, sugar production, duration and molasses production from 1930–31 to 2011–12. Indian Sugar 63(3): 48–49.

Boast, M.M. 1994. Evaluation of detrashing components for a green cane harvester. Proceedings of the South African Sugar Technologists Association 68: 51–54.

Kojima, S.M.A.Y.M., and S. Kashiwagi. 1986. On the pulling force of leaf stripping roll for sugarcane. Bulletin of the Faculty of Kagoshima University, Japan 26: 215–219.

Sandhar, N.S., L.N. Shukla, and V.K. Sharma. 1999. Studies on mechanical properties of sugarcane and their relevance to cleaning. In Souvenir-34th ISAE Annual Convention of ISAE held at CCS Haryana Agricultural University, Hisar on Dec. 16–18, FMP 20.

Shukla, L.N., I. Singh, and N.S. Sandhar. 1991. Design development and testing of sugarcane cleaner. Agricultural Mechanization in Asia, Africa and Latin America 22(3): 55–58.

Singh, A.K., and M.P. Sharma. 2009. Equipment to remove trash from harvested cane stalks for cleaning. In Souvenir-43rd Annual Convention of ISAE & Symposium organized at Birsa Agricultural University on Feb. 15–17, 123.

Singh, A.K., P.R. Singh, and R. Gupta. 2012. Mechanization of sugarcane harvesting in India. Journal of Sugarcane Research 2(2): 9–14.

Srivastava, A.C., and K. Singh. 1990. Development of a power driven sugarcane detrasher. Agricultural Mechanization in Asia, Africa and Latin America 21(2): 49–52.

Tambosco, N., J.P.B. Teixeira, L.G. Filho, E.J. Ustulin, J.L.P. Henrique, O. Alonso, W.J. Correa, R.N.G. Franceschi, J.C. Salata, and G.E. Serra. 1977. Trash in mechanical and manual harvesting of sugarcane. Proceedings of the Congress of the International Society of Sugarcane Technologists 16: 1975–1979.

Acknowledgments

Authors are thankful to the technicians of Division of Agricultural Engineering, Indian Institute of Sugarcane Research, Lucknow for their help and support in fabrication and testing of the prototype.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.K., Solomon, S. Development of a Sugarcane Detrasher. Sugar Tech 17, 189–194 (2015). https://doi.org/10.1007/s12355-014-0306-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-014-0306-5