Abstract

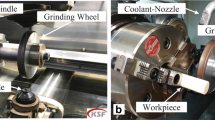

This paper presents selected results of the grinding of silicon nitride and cemented carbide materials with diamond grinding wheels, which will in later research be extended to the grinding of ceramic-cemented carbide compound drill tools. In these fundamental experiments four different types of diamond grinding wheels were used in face grinding processes. The diamond grinding wheels vary by the grain size, the grain concentration and the bonding material. The relevant influencing variables such as the cutting and feed speed and the coolant supply method were varied to investigate the effect on grinding of the two different workpiece materials, the brittle silicon nitride workpiece material and the ductile cemented carbide workpiece material. Some factors, which have significant effects, like the radial wear of the grinding wheel, the components of the grinding forces, the normal and the tangential grinding force, and the surface quality of the ground workpieces are discussed in detail.

Similar content being viewed by others

References

Friemuth T, Hessel D, Reichstein M, Meer M (2006) Bearbeitung keramischer Werkstoffe. Tribologie und Schmierungstechnik 53:29–36

Weinert K, Bach FW, Deißer TA, Peters C (2004) Development of an active brazed ceramic-cemented carbide compound drill. Adv Eng Mater 6:153–157

Peters C (2005) Herstellung und Einsatzverhalten von Keramik-Hartmetall-Verbundbohrwerkzeugen. Dissertation, Universität Dortmund

Li K, Liao TW (1997) Modelling of ceramic grinding processes. Part 1. Number of cutting points and grinding forces per grit. J Mater Process Technol 65:1–10

Zhang LC, Suto T, Noguchi H, Waida T (1995) A study of creep-feed grinding of metallic and ceramic materials. J Mater Process Technol 48:267–274

Biermann D, Würz E (2008) Schleifbearbeitung von Hart-Weich-Verbunden—Finite-Elemente-Simulation des Schleifprozesses von hybriden Schichtverbunden. Materialwissenschaft und Werkstofftechnik. doi:10.1002/mawe.200800335

Tönshoff HK, Denkena B, Friemuth T, Glatzel T, Stahl M (2003) Grinding of a ceramic steel compound. Prod Eng 10:1–4

Weinert K, Hesterberg S, Buschka M (2004) Hochharte Schneidstoffe für die spanende Bearbeitung pulvermetallurgischer Hartlegierungen—Teil 1: Drehen. Industrie Diamanten Rundschau 38:122–129

Uhlmann E (1998) Surface formation in creep feed grinding of advanced ceramics with and without ultrasonic assistance. CIRP Ann—Manuf Technol 47:249–251

Denkena B, Reichstein M, Karyazin A (2005) Schleifbearbeitung von Verbundwerkstoffen aus Stahl und Keramik mit Diamantwerkzeugen. Industrie Diamanten Rundschau 39:332–338

Schneider M (1999) Auswirkungen thermomechanischer Vorgänge beim Werkzeugschleifen. Dissertation, Universität Dortmund

Biermann D, Würz E (2009) Schleifbearbeitung von Keramik und Hartmetall mit Diamantschleifscheiben. Diamond Bus 29:44–52

Clausen R, Brevern P (1996) Tiefschleifen von Hartmetall mit Diamantschleifscheiben. Teil 1—Tiefschleifen mit Emulsion. Industrie Diamanten Rundschau 30:185–189

Brevern P (2008) Deep grinding of different grades of tungsten carbide with oil as lubricating coolant. Ind Diamond Rev 68:47–48

Tönshoff HK, Friemuth T, Hessel D, Lierse T (1999) Mechanical and thermal effects in grinding of advanced ceramics. Int J Jpn Soc Precis Eng 33:32–36

Schulte M (2004) Profilschleifen von Hartlegierungen und Hartverbundwerkstoffen mit konventionellen Schleifmitteln. Dissertation, Universität Dortmund

Brinksmeier E, Heinzel C, Wittmann M (1999) Friction, cooling and lubrication in grinding. Ann of the CIRP 48:581–598

Brücher T, Spur G, Laufer J (1998) Kühlschmierung beim Schleifen keramischer Werkstoffe. Int Colloq Tribol 11:141–150

Acknowledgments

This research project TP 8 “Grinding of ceramic–metal compounds” as a part of the Research Training Group (Graduiertenkolleg GRK 1378/1) “Manufacture, machining and qualification of hybrid material systems” is kindly supported by the German Research Foundation (Deutsche Forschungsgemeinschaft DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biermann, D., Würz, E. A study of grinding silicon nitride and cemented carbide materials with diamond grinding wheels. Prod. Eng. Res. Devel. 3, 411 (2009). https://doi.org/10.1007/s11740-009-0183-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11740-009-0183-z