Abstract

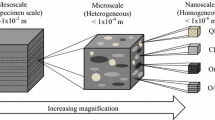

Despite the importance of organic-rich shales, microstructural characterization and theoretical modeling of these rocks are limited due to their highly heterogeneous microstructure, complex chemistry, and multiscale mechanical properties. One of the sources of complexity in organic-rich shales is the intricate interplay between microtextural evolution and kerogen maturity. In this study, a suite of experimental and theoretical microporomechanics methods are developed to associate the mechanical properties of organic-rich shales both to their maturity level and to the organic content at micrometer and sub-micrometer length scales. Recent results from chemomechanical characterization experiments involving grid nanoindentation and energy-dispersive X-ray spectroscopy (EDX) are used in new micromechanical models to isolate the effects of maturity levels and organic content from the inorganic solids. These models enable attribution of the role of organic maturity to the texture of the indented material, with immature systems exhibiting a matrix-inclusion morphology, while mature systems exhibit a polycrystal morphology. Application of these models to the interpretation of nanoindentation results on organic-rich shales allows us to identify unique clay mechanical properties that are consistent with molecular simulation results for illite and independent of the maturity of shale formation and total organic content. The results of this investigation contribute to the design of a multiscale model of the fundamental building blocks of organic-rich shales, which can be used for the design and validation of multiscale predictive poromechanics models.

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm F-J (2016) Nano-chemomechanical signature of organic-rich shales: a coupled indentation-EDX analysis. Acta Geotech 11(3):559–572

Allan AM, Clark AC, Vanorio T (2015) Pyrolysis-induced evolution of the elastic and transport properties of the barnett shale. SEG Annual Meeting, 18–23 October, New Orleans, Louisiana

Beneviste Y (1987) A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech Mater 6:147–157. doi:10.1016/0167-6636(87)90005-6

Bobko CP (2008) Assessing the mechanical microstructure of shale by nanoindentation: the link between mineral composition and mechanical properties. PhD dissertation, Massachusetts Institute of Technology, Cambridge

Bobko C, Ulm J (2008) The nano-mechanical morphology of shale. Mech Mater 40(4–5):318–337

Cariou S, Ulm F-J, Dormieu L (2008) Hardness–packing density scaling relations for cohesive-frictional porous materials. J Mech Phys Sol 56:924–952. doi:10.1016/j.jmps.2007.06.011

Chen JJ, Sorelli L, Vandamme M, Ulm F-J, Chanvillard G (2010) A coupled nanoindentation/SEM-EDS study on low water/cement ratio portland cement paste: evidence for C-S–H/Ca(OH)2 nanocomposites. J Am Ceram Soc 93(5):1484–1493. doi:10.1111/j.1551-2916.2009.03599.x

Constantinides G, Ulm F-J (2007) The nanogranular nature of C–S–H. J Mech Phys Solids 55(1):64–90

Deirieh A, Ortega JA, Ulm F-J, Abousleiman Y (2012) Nanochemomechanical assessment of shale: a coupled WDS-indentation analysis. Acta Geotech 7:271–295. doi:10.1007/s11440-012-0185-4

Delafargue A, Ulm F-J (2004) Explicit approximations of the indentation modulus of elastically orthotropic solids for conical indenters. Int J Sol Struct 41:7351–7360. doi:10.1016/j.ijsolstr.2004.06.019

Dormieux L, Chateau X (2002) Micromechanics of saturated and unsaturated porous media. Int J Numer Anal Meth Geomech 26(8):831–844. doi:10.1002/nag.227

Dormieux L, Molinari A, Kondo D (2002) Micromechanical approach to the behavior of poroelastic materials. J Mech Phys Sol 50(10):2203–2231. doi:10.1016/S0022-5096(02)00008-X

Dormieux L, Kondo D, Ulm F-J (2006) Microporomechanics. Wiley, Chichester. doi:10.1002/0470032006

Ebrahimi D, Pellenq RJ-M, Whittle AJ (2012) Nanoscale elastic properties of montmorillonite upon water adsorption. Langmuir 28(49):16855–16863

Espitalié J, Laporte JL, Madec M, Marquis F, Leplat P, Paulet J, Boutefeu A (1977) Méthode rapide de caractérization des roches mères, de leur potential pétrolier et de leur degré d’évolution. Revue de L’Institut Français du Pétrole 32(1):23–42. doi:10.2516/ogst:1977002

Fitzgerald JJ, Hamza AI, Bronnimann CE, Dec SF (1989) Solid-state 27 Al and 29 Si NMR studies of the reactivity of the aluminum-containing clay mineral kaolinite. Sol State Ionics 32–33(Part 1):378–388

Fritsch A, Dormieux L, Hellmich C, Sanahuja J (2007) Micromechanics of crystal interfaces in polycrystalline solid phases of porous media: fundamentals and application to strength of hydroxyapatite biomaterials. J Mater Sci 42(21):8824–8837. doi:10.1007/s10853-007-1859-4

Gathier B (2008) Multiscale strength homogenization: application to shale nanoindentation. S. M. dissertation, Massachusetts Institute of Technology, Cambridge

Gayer J, Prasad M, Batzle M (2015) Comparison of anhydrous to hydrous pyrolysis effects on oil shale core samples from the Iratì Formation in the Paraná Basin, Brazil. SEG Annual Meeting, 18–23 October, New Orleans, Louisiana

Hantal G, Brochard L, Laubie H, Ebrahimi D, Pellenq R, Ulm F-J, Coasne B (2014) Atomic-scale modelling of elastic and failure properties of clays. Mol Phys, 112(9–10). doi: 10.1080/00268976.2014.897393

Hellmich C, Barthelemy J-F, Dormieux L (2004) Mineral–collagen interactions in elasticity of bone ultrastructure—a continuum micromechanics approach. Eur J Mech A Sol 23(5):783–810. doi:10.1016/j.euromechsol.2004.05.004

Kuila U, McCarty DK, Derkowski A, Fischer TB, Topór T, Prasad M (2014) Nano-scale texture and porosity of organic matter and clay minerals in organic-rich mudrocks. Fuel 135:359–373. doi:10.1016/j.fuel.2014.06.036

Mavko G, Mukerji T, Dvorkin J (2009) Rock physics handbook: tools for seismic analysis in porous media. Cambridge University Press, Cambridge

Monfared S, Ulm F-J (2016) A molecular informed poroelastic model for organic-rich, naturally occurring porous geocomposites. J Mech Phys Sol (in press)

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metallurgic 21(5):571–574. doi:10.1016/0001-6160(73)90064-3

Okiongbo KR, Aplin AC, Larter SR (2005) Changes in type II kerogen density as a function of maturity: evidence from the Kimmeridge Clay Formation. Energ Fuels 19(6):2495–2499

Ortega JA, Ulm F-J, Abousleiman Y (2009) The nanogranular acoustic signature of shale. Geophysics 74(3):D65–D84. doi:10.1190/1.3097887

Prasad M, Mukerji T (2003) Analysis of microstructural textures and wave propagation characteristics. In: Shales SEG Annual Meeting, 26–31 October, Dallas, Texas

Prasad M, Mukerji T, Reinstaedler M, Arnold W (2009a) Acoustic signatures, impedance microstructure, textural scales, and anisotropy of Kerogen-Rich shales. SPE Annual Technical Conference and Exhibition, 4–7 October, New Orleans, Louisiana, doi: 10.2118/124840-MS

Prasad M, Mba KC, McEvoy E, Batzle ML (2009b) Maturity and impedance analysis of organic-rich shales. Society of Petroleum Engineers. SPE 123531. doi:10.2118/123531-MS

Sone H, Zoback MD (2013) Mechanical properties of shale gas reservoir rocks—Part 1: Static and dynamic elastic properties and anisotropy. Geophysics 78. doi: 10.1190/geo2013-0050.1

Ulm F-J, Vandamme M, Bobko C, Ortega JA (2007) Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J Am Ceram Soc 90(9):2677–2692. doi:10.1111/j.1551-2916.2007.02012.x

Vernik L, Kachanov M (2010) Modeling elastic properties of siliciclastic rocks. Geophysics 75(6):E171–E182

Vernik L, Landis C (1996) Elastic anisotropy of source rocks: implications for hydrocarbon generation and primary migration. AAPG Bulletin 80(4):531–544

Vernik L, Nur A (1992) Ultrasonic velocity and anisotropy of hydrocarbon source rocks. Geophysics 57:727–735

Zaoui A (2002) Contiuum micromechanics: a survey. J Eng Mech 128:808–816. doi:10.1061/(ASCE)0733-9399(2002)128:8(808)

Zargari S, Prasad M, Mba KC, Mattson ED (2013) Organic maturity, elastic properties, and textural characteristics of self resourcing reservoirs. Geophysics 78(4):D223–D235. doi:10.1190/GEO2012-0431.1

Zhang G, Wei Z, Ferrell RE (2009) Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl Clay Sci 43(2):271–281

Acknowledgments

This work was conducted as part of the X-Shale Project, an industry-academia partnership between MIT, Shell and Schlumberger enabled through MIT’s Energy Initiative. Shell and Schlumberger provided all the samples used in this study. The experimental results were obtained in the X-Hub laboratory at MIT: https://cshub.mit.edu.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abedi, S., Slim, M. & Ulm, FJ. Nanomechanics of organic-rich shales: the role of thermal maturity and organic matter content on texture. Acta Geotech. 11, 775–787 (2016). https://doi.org/10.1007/s11440-016-0476-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-016-0476-2