Abstract

The increase disposals of fly ash from solid waste incinerator have becoming a serious environmental problem in China. Levels of PAHs in fly ash from a selected full-scale miscellaneous solid waste incinerator were determined by gas chromatograph/mass spectrometer. Content of trace elements and other major elements of fly ash were studied by inductively coupled plasma-mass spectrometry and X-ray fluorescence spectrometry, respectively. Experimental results showed that a high content of lead occurred in the collected fly ash samples with the value of 35,037.90 µg/kg, but lower contents of total 16 PAHs, which mainly smaller PAHs. This was different from previous studies regarding the levels of PAHs in fly ash collected from the similar hospital waste incinerators. This survey indicated that the emission factors are attributed to combustion temperatures, type of incinerator, and the occurrences of elements in solid wastes. The total toxic equivalent quantities (TEQ) value of PAHs, a potential toxicity risk assessment using index TEQ model, has been reached to 4.00 µg/kg in ash from this study, but may not suitable for the soil amendment. Therefore, a further treatment of discharged ash and assessment of its environmental risk are unavoidable.

Similar content being viewed by others

1 Introduction

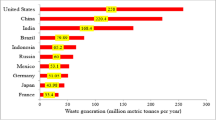

China, one of the fastest developing countries, is the world’s largest solid waste generator due to rapid industrialization and urbanization in the last two decades (Duan et al. 2008; Huang et al. 2006; Zhang et al. 2010). Take the industry solid waste (ISW), for example, the total quantity has increased alarmingly year by year, which increased from 0.8 billion tons in 1998 to 3.2 billion tons in 2011, according to the statistical records of the ISW (China Statistical Yearbook 1998–2011). Statistic quantity of ISW was about 3.3 billion tons in 2012 (Chinese Environmental Yearbook 2012). At present, more than half of total ISW is reused in China (Fig. 1), while there is still vast majority of ISW-treated stock subsequently discharged into the environment. Solid waste crisis is serious in China (Liu et al. 2006; Tian et al. 2013). Due to the limited land available for landfills, incineration is safe and effective option for waste management as it could significantly reduce the volume and weight of waste and destroy pathogens and toxic organic compounds (Liu et al. 2000b). However, fly ash is inevitable during waste incineration, accounting for 10–30 wt% of the original amount of waste (Tian et al. 2012; Zhang et al. 2008). Most of them are characterized by high enrichment of toxic chemicals such as trace elements and organic pollutants (Koukouzas et al. 2011; Tang et al. 2013; Wang et al. 2010). These pollutants are likely to return into the environment and cause secondary pollution and thus into the food web, if improper management (Dolk et al. 1998). For this reason, fly ash is seen as hazardous materials and needs to specially manage in many countries (Haugsten and Gustavson 2000). Polycyclic aromatic hydrocarbons (PAHs), one typical persistent toxic substance, consist of 2–6 condensed aromatic rings (Directive 2000), which are one of the main organic contaminants in fly ash particle that have been added into the list of the priority pollutants and the emission standards by the World Health Organization, as well as America, France, Germany, Japan, Netherlands, Sweden, and Switzerland (Wilson and Jones 1993; OECD 1989; Environment Australia 1999; World Health Organization 1985; WHO 2000; Wilson and Jones 1993). Large amount of study about the PAH characteristics focused on coal, municipal solid wastes (MSW), biomass, industrial hazardous, and medical wastes (Bozlaker et al. 2008; Johansson and van Bavel 2003b; Lee et al. 2002; Liu et al. 2001; McGrath et al. 2001). To the best of authors’ knowledge, however, only limited data are available in the research about the PAHs in the fly ash from the miscellaneous waste combustion. In addition, no official standards have been issued for PAHs in the fly ash and quite few contamination prevention measures have been made for fly ash in China. Therefore, it is necessary to investigate the PAH concentrations in miscellaneous waste combustion to fill this gap. In the present work, we address this aspect by discussing the characteristics of fly ash from a miscellaneous solid waste incinerator in China.

2 Samples and methods

2.1 Basic information on incinerator and sampling

The investigation was carried out in a rotary kiln incinerator located in the east of China. The incinerator began operation during the outbreak of severe acute respiratory syndrome (SARS) in 2003 with the capacity of 6,000 t/year solid waste (Table 1). Solid waste incinerated is very heterogeneous and mainly consists of hospital waste (HW; 65 %) and industries hazardous waste (35 %). The incinerator is equipped with an air pollution control device of bag filter as shown schematically in Fig. 2. To obtain representative samples, fly ash samples were taken directly from the hopper of the bag filter when the system tuning to a stable condition on five successive days; then, five fly ash samples were kept in vacuum-sealed bags before analysis.

2.2 Methods

All the samples for trace element analysis were crushed and ground to pass a 200-mesh sieve after dried at 105 °C for 24 h. Physicochemical parameters including particle size distribution and specific surface were determined by laser diffraction particle size analyzer (Better BT 2003) and nitrogen adsorption–desorption isotherms, respectively.

Content of trace elements in fly ash was determined by inductively coupled plasma-mass spectrometry (ICP-MS) after digestion by an acid mixture of HNO3:HCl:HF (3:1:1) in closed vessels with microwave oven. The chemical composition was determined by X-ray fluorescence spectrometry (XRF) following the method ASTM D4326-2001. The accuracy of the analytical method was determined by analyzing standard reference material NBS1633b. The recovery rates of the trace element were within the certificate values.

Method for PAH analysis is consistent with the previous analysis process, which has been described previously (Liu et al. 2012). Samples were dried at 30 °C for 24 h, crushed and sieved through a 200-mesh sieve. About 15 g of pretreated sample was extracted in a Soxhlet extractor with 250 mL dichloromethane for 48 h. Two grams of activated copper piece was added to remove sulfur. The extract was preconcentrated to a volume of 1 mL by rotary evaporation, and its solvent was exchanged for hexane. The concentrated solution (~2 mL) was injected to pass through a purifying tube packed with silica gel and neutral alumina. After eluting with 70 mL of the methylene dichloride-hexane (3:7 v/v) mixture, the PAH fractions were concentrated to 1.5 mL under a gentle stream of N2.

Determination of PAHs was conducted on a Shimadzu model 2010 GC–MS instrument equipped with an AOC-20i autoinjector (Shimadzu, Japan), using electron impact mode (70 eV) in the selected ion monitoring mode. The DB-5 column of 60 m × 0.25 mm inner diameter (0.25 μm film thickness) was used. The GC temperature increased from 60 to 200 °C at 5 °C/min, to 250 °C at 2 °C/min, and then to 290 °C at 20 °C/min and further hold for 20 min at 290 °C. The carrier gas Helium (99.9999 % purity) was used as carrier gas at a constant flow rate of 1.0 ml/min.

The quantitative analysis was done by the internal calibration method (five-point calibration), and PAH identification was performed by comparison of their retention time with standards. A mixture of internal standards 2-fluoro-1, 1-biphenyl, p-terhenyl-d14 and dibenzo(a,h)anthracene-d14 was added to the sample just before injection. 2-Fluoro-1 and 1-biphenyl were used for Naph, Acy, Acen, and Flu; p-terhenyl-d14 was used for Phen, Anth, Flan, Pyr, B[a]A, Chry, B[b]F, B[k]F, and B[a]P; dibenzo(a,h)anthracene-d 14 was used for IP, DB[ah]A, and B[ghi]P.

Reagent blanks, duplicate samples, and the standard additions were analyzed along with samples through the procedures of extraction and cleanup. Reagent blank samples contained no detectable amounts of the monitoring PAHs. Surrogate standards containing five deuterated PAHs (naphthalene-d8, acenaphthene-d10, phenanthrene-d10, chrysene-d12, and perylene-d12) were added to all samples before extraction to determine the recovery rate of the analysis process. The surrogate recoveries were 67.2 ± 4.52 % for naphthalene-d8; 75.4 ± 4.67 % for acenaphthene-d10; 88.1 ± 6.41 % for phenanthrene-d10; 94.8 ± 4.35 % for chrysene-d12; and 98.5 ± 6.59 % for perylene-d12 with fly ash samples. Meanwhile, recoveries of 16 PAHs in the NIST1941 reference sample were between 80 and 120 % of the certified values provided by the NIST.

3 Results and discussion

3.1 Physiochemical properties of collected fly ash

The particle size was determined by laser diffraction particle size analyzer (Better BT 2003), and the result was given in Fig. 3. The particle sizes of most ash were within a range of 0.079–30.67 μm, accounting for more than 90 wt% of the total ash mass. The average particle size was 9.85 μm. Similar ranges of ash particle size have been found in previous studies. For example, Cobo et al. (2009) reported that about 75 wt% of the total mass of fly ash collected from the bag house of a hazardous waste incinerator. Nagib and Inoue (2000) found about 80 wt% of the total mass of fly ash from the MSW incinerator has particle size <20 μm. Moreover, the fly ash is characterized by tri-modal particle size distribution, which includes a smallest ultrafine region centered at approximately 0.2 μm, a fine fragmentation centered at 8 μm, and a bulk fragmentation region for particles of approximately 15 μm diameter. The smallest fly ash particle was formed mainly by solid–vapor–particle processes, including vaporization, nucleation, condensation, and coagulation of inorganic constituents in the waste (Xu et al. 2011). The central mode may attribute to the coagulated fine particles or micrometer-size fuel materials (Yu et al. 2009). Fusion and coalescence of the inorganic material in the fuel should be mainly responsible for the coarse-mode formation.

The nitrogen adsorption–desorption isotherms of this fly ash are shown in Fig. 4. Based on the IUPAC classification, the adsorption isotherms of this ash attribute to the Type II adsorption, indicating a presence of micropores (larger than 2 nm). As presented in Table 2, the SBET of ash particle size was found to be 3.92 m2/g and also suggests the porosity of particles.

The chemical composition of ash samples was analyzed using XRF, and the result was illustrated in Table 3; SiO2 was the most abundant component in ash sample followed by A12O3 and Fe2O3. The least abundant major components were MnO, SO3, and P2O5. Higher content of SiO2 makes a more fixed structure to restrain trace element from leaching (Song et al. 2004).

3.2 Trace element in fly ash

Although trace elements have much less proportions in view of the unit mass of fly ash, the large amount production of fly ash from solid waste incinerator will significantly increase amounts and risks of the released trace elements into the environment. This generally occurs during the landfilling disposal under natural conditions. The mean content of selected 10 trace elements in fly ash is shown in Table 3. Higher contents of volatile trace elements were found to be bound to the collected ash that was consistent with the results reported in previous works (Cobo et al. 2009; Eighmy et al. 1995). Especially, lead is an element with the highest content in all the samples in this study, and its content in the ash reaches 35,037.90 µg/kg. This may due to the different physicochemical properties of elements and their content in the solid waste (Chang et al. 2009). Increasing the combustion temperatures, some low-boiling point trace elements, such as Zn, Pb, Cd, and Cu, preferably volatilized in combustion zone and formed the uniform small particles and then condensed on the fly ash in the decreasing temperature flue gas convective pass to stack (Song et al. 2004). In China, there has not been setup of regulation in trace elements in fly ash from specific HWs. Based on the available standard issued by the California EPA, which is 5,000 µg/kg, the content of Pb in the current fly ash far more exceeds this regulatory thresholds. Therefore, fly ash in the incinerator should be properly disposed to reduce its environmental risks; otherwise, it may affect humans by the food chain.

3.3 Content of PAHs in fly ash

PAHs are a group of semi-volatile organic compounds that consist of 2–6 condensed aromatic rings (Kong et al. 2011; Sun et al. 2006; Yang et al. 2002). Many of these compounds are known as carcinogenic, mutagenic, and teratogenic. Some PAHs adsorbed on ash can cause serious environmental pollution and can persistent in the environment for months due to their stable structure if they evaporate into the atmosphere (Liu et al. 2000a, 2008). That’s why the US Environmental Protection Agency has issued a list of priority pollutants to be monitored in the environment, including 16 PAHs according to their toxicity (Callahan 1979; Ravindra et al. 2001).

The total content and individual contents of the 16 USEPA priority PAHs found in the fly ash samples are summarized in Table 4. The results showed that the total content of PAHs was 2,444.90 µg/kg, PAHs of five to six rings (Big PAHs) were not detected, and the content of most toxic PAH (B[a]P) was not found. PAHs with two to four rings (small PAHs) have been identified in fly ash samples. Naphthalene is the most abundant PAH present in samples with a content of 1,940.64 µg/kg. The content of the 7 USEPA carcinogenic PAHs (ΣPAHscarc: BaA, CHR, BbF, BkF, BaP, IcdP, and DahA) was 65.28 µg/kg and accounted for 2.7 % of the total PAH content in mass.

Emission of PAHs from solid waste was determined by the combustion conditions of incinerators, mainly referring to temperatures, retention times, and incinerator structures (Singh and Prakash 2007). In a low-temperature stage (below 800 °C), the major pathway for the formation of PAHs is pyrolysis of solid wastes, resulting in the formation of small PAHs. While the large PAHs are produced during the deep degradation and/or combination of small PAHs in a higher temperature (Wheatley and Sadhra 2004; Yan et al. 2004; Zhao et al. 2000), study of Singh and Prakash (2007) acclaimed the highest content of total PAHs in fly ash at 1,000 °C.

As for the current rotary kiln incinerator, lower combustion temperature was applied (850 °C) in the first combustion chamber. This may partly explain better prevention of PAHs during combustion of solid wastes. Studies of Van Caneghem et al. (2010, 2014) were shown that the PCBs (polychlorinated biphenyls) in rotary kiln have been destroyed effectively during incineration by mass balance method. Li et al. (2004) also confirmed the increase of PAHs content, especially small PAHs, upon the increase of combustion temperature. Thus, he suggested two-stage combustion of solid wastes. Temperature in the first combustion chamber was about 800 °C, and it was followed up by the second combustion chamber, controlling the temperature at about 1,000 °C and residence time at 2 s for a complete combustion of the vaporizing PAHs from the first chamber. The basic procedure occurrence of PAHs generated in ash, as shown in Table 4. Small PAHs have higher stability and can travel over a longer distance due to their higher boiling point comparing to large PAHs (Chen et al. 2003; Lai et al. 2007; Liu et al. 2000a; Tsai et al. 2002). Because of this, small PAHs usually cause higher risks than big PAHs although they have little carcinogenicity effect.

Comparing with the earlier study by Wild et al. (1992), it was found the amount of 16 PAHs in fly ash from coal combustion and MSW incinerators was 354 and 227 µg/kg, respectively. Results of similar studies (Chen et al. 2003; Lee et al. 2002; Levendis et al. 2001; Zhao et al. 2008) of PAH contents in fly ash from HW incinerators are shown in Fig. 5. The content of PHAs in fly ash in this study was higher than in coal fly ash and MSW fly ash and much lower than in HW fly ash in other studies. This difference can possible interpreted as the higher calorific value of solid waste in this study with more content of plastic, accounting for 13–18 % in medical waste (Chen et al. 2013; Fang et al. 2005). Another factor that may cause the high PAHs in the ash is the inherently higher PAH content in the waste components (Wheatley and Sadhra 2004). Meanwhile, the presence of Pb in fly ash may facilitate the formation of PAH, which have been discussed by Wey et al. (2000).

3.4 Potential toxicity risk assessment for PAHs in fly ash

Since no environmental standards for PAHs in ash are established in China, standards developed in Swedish and Dutch were adopted to evaluate the PAH contamination. Guidelines for PAHs in land-use limit have been developed by Swedish EPA, Netherland EPA, and Canada EPA, and for sensitive land use, the limits are set to 300, 120, and 500 µg/kg, respectively (Johansson and van Bavel 2003a; Canada EPA 2003; Swedish EPA 2002). Also, a standard carried out by Dutch shows the target value as 1,000 µg/kg for 10 PAHs (naphthalene, anthracene, phenanthrene, fluoranthene, benzo(a)anthracene, chrysene, benzo(a)pyrene, benzo(g,h,i)perylene, benzo(k)fluoranthene, and indeno(1,2,3-c,d)pyrene) of unaffected soil and 4,000 µg/kg for soil that required restore (Van Brummelen et al. 1996). Thus, the content of PAHs for fly ash in this study has not exceeded the limits of sensitive land use, but exceeded the limit of Dutch EPA for about 2 times. Therefore, integrated utilization of the fly ash in this study should be performed with caution.

Index toxic equivalent quantities (TEQ) associated with PAHs are used to evaluate the potential health risk of PAHs to ecosystems and human beings. Value of TEQi was calculated for each PAH according to the content in the sample and its toxic equivalency factor from the literature (Nisbet and LaGoy 1992). The total TEQ value was calculated by \({\text{TEQ}} = \mathop \sum \nolimits ({\text{TEQ}}_{\text{i}} ) = \mathop \sum \nolimits ({\text{C PAH}}_{\text{i}} \times {\text{TEF PAH}}_{\text{i}} )\), and the results are listed in Table 4. From the study of Nisbet and Lagoy, benzo(a)pyrene and Dibenz(a,h)anthracene are the two most potent carcinogenic PAHs, although they were not detected in the current study. The total TEQ value was 4.00 µg/kg, which is lower than the value of 15 µg/kg for soil by USEPA (2012).

4 Conclusion

The average particle size of discharged fly ash from the incinerator is 9.85 μm, ranging from 0.079 to 30.67 μm, which accounting for more than 90 wt% of the total ash mass. The collected fly ash has only a minimal specific surface area of 3.92 m2/g and a negligible porosity. Chemical characteristics, using XRF and ICP-MS, revealed the most abundant component is SiO2 and Pb is a trace element in the highest content with the value of 35,037.90 µg/kg. Fly ash in this study presented a different levels and patterns of PAHs, for having lower content of total 16 PAHs, and mainly consists of small PAHs, comparing with HW ash. These differences would contribute to the combustion temperature and the high content of lead in solid waste. The amount of PAHs in fly ash did not exceed the guidelines for sensitive land use. However, the ash should be regulated carefully before disposition for the high content of lead.

References

Bozlaker A, Muezzinoglu A, Odabasi M (2008) Atmospheric concentrations, dry deposition and air–soil exchange of polycyclic aromatic hydrocarbons (PAHs) in an industrial region in Turkey. J Hazard Mater 153:1093–1102

Callahan MA (1979) Water-related environmental fate of 129 priority pollutants, vol 1. Office of Water Planning and Standards, Office of Water and Waste Management, US Environmental Protection Agency

Canada EPA (2003) Canadian soil quality guidelines. Environment Canada, Canada

Chang C-Y, Wang C-F, Mui D, Cheng M-T, Chiang H-L (2009) Characteristics of elements in waste ashes from a solid waste incinerator in Taiwan. J Hazard Mater 165:766–773

Chen S-J, Hsieh L-T, Chiu S-C (2003) Characteristics of the PAH emissions from the incineration of livestock wastes with/without APCD. Environ Int 28:659–668

Chen Y, Zhao R, Xue J, Li J (2013) Generation and distribution of PAHs in the process of medical waste incineration. Waste Manag 33:1165–1173

China Statistical Yearbook 1998–2011 http://www.mep.gov.cn/zwgk/hjtj/

Chinese Environmental Yearbook Compiling Committee (2012) Chinese Environment Yearbook of 2012, SEPA, June 2012 http://jcs.mep.gov.cn/hjzl/zkgb/2012zkgb/ (in Chinese)

Cobo M, Gálvez A, Conesa JA, Montes de Correa C (2009) Characterization of fly ash from a hazardous waste incinerator in Medellin, Colombia. J Hazard Mater 168:1223–1232

Directive Council (2000) 76/EC of the European parliament and of the council of 4 December 2000 on the incineration of waste. Off J Eur Communities 28:91–111

Dolk H et al (1998) Risk of congenital anomalies near hazardous-waste landfill sites in Europe: the EUROHAZCON study. Lancet 352:423–427

Duan H, Huang Q, Wang Q, Zhou B, Li J (2008) Hazardous waste generation and management in China: a review. J Hazard Mater 158:221–227

Eighmy TT, Eusden JD, Krzanowski JE, Domingo DS, Staempfli D, Martin JR, Erickson PM (1995) Comprehensive approach toward understanding element speciation and leaching behavior in municipal solid waste incineration electrostatic precipitator ash. Environ Sci Technol 29:629–646

Environment Australia (1999) Polycyclic aromatic hydrocarbons (PAHs) in Australia. Technical report No. 2. http://www.environment.gov.au/atmosphere/airquality/publications/report2/pubs/report2.pdf

Fang L, Jihua C, Danli X, Jialu S (2005) Research on output, composition and disposal countermeasures of municipal domestic waste in Shanghai City. Environ Sanit Eng 2:012

Haugsten KE, Gustavson B (2000) Environmental properties of vitrified fly ash from hazardous and municipal waste incineration. Waste Manag 20:167–176

Huang Q, Wang Q, Dong L, Xi B, Zhou B (2006) The current situation of solid waste management in China. J Mater Cycles Waste Manag 8:63–69

Johansson I, van Bavel B (2003a) Levels and patterns of polycyclic aromatic hydrocarbons in incineration ashes. Sci Total Environ 311:221–231

Johansson I, van Bavel B (2003b) Polycyclic aromatic hydrocarbons in weathered bottom ash from incineration of municipal solid waste. Chemosphere 53:123–128

Kong S et al (2011) Characterization of PAHs within PM10 fraction for ashes from coke production, iron smelt, heating station and power plant stacks in Liaoning Province, China. Atmos Environ 45:3777–3785

Koukouza N, Ketikidis C, Itskos G (2011) Heavy metal characterization of CFB-derived coal fly ash. Fuel Process Technol 92(3):441–446

Lai Y-C, Lee W-J, Huang K-L, Huang H-H (2007) Emissions of polycyclic aromatic hydrocarbons from thermal pre-treatment of waste hydrodesulfurization catalysts. Chemosphere 69:200–208

Lee W-J, Liow M-C, Tsai P-J, Hsieh L-T (2002) Emission of polycyclic aromatic hydrocarbons from medical waste incinerators. Atmos Environ 36:781–790

Levendis YA, Atal A, Carlson JB, del Mar Esperanza Quintana M (2001) PAH and soot emissions from burning components of medical waste: examination/surgical gloves and cotton pads. Chemosphere 42:775–783

Li S-Q, Yao Q, Chi Y, Yan J-H, Cen K-F (2004) Pilot-scale pyrolysis of scrap tires in a continuous rotary kiln reactor. Ind Eng Chem Res 43:5133–5145

Liu K, Xie W, Zhao Z-B, Pan W-P, Riley JT (2000a) Investigation of polycyclic aromatic hydrocarbons in fly ash from fluidized bed combustion systems. Environ Sci Technol 34:2273–2279

Liu Z-q, Li J-h, Nie Y-f (2000b) Development trend and policy analysis on prevention and control technology of hazardous waste pollution in China [J]. China Environ Prot Ind 6:15–17

Liu K, Han W, Pan W-P, Riley JT (2001) Polycyclic aromatic hydrocarbon (PAH) emissions from a coal-fired pilot FBC system. J Hazard Mater 84:175–188

Liu Z, Liu Z, Li X (2006) Status and prospect of the application of municipal solid waste incineration in China. Appl Therm Eng 26:1193–1197

Liu G, Niu Z, Van Niekerk D, Xue J, Zheng L (2008) Polycyclic aromatic hydrocarbons (PAHs) from coal combustion: emissions, analysis, and toxicology. Reviews of environmental contamination and toxicology. Springer, New York, pp 1–28

Liu J, Liu G, Zhang J, Yin H, Wang R (2012) Occurrence and risk assessment of polycyclic aromatic hydrocarbons in soil from the Tiefa coal mine district Liaoning, China. J Environ Monit 14:2634–2642

McGrath T, Sharma R, Hajaligol M (2001) An experimental investigation into the formation of polycyclic-aromatic hydrocarbons (PAH) from pyrolysis of biomass materials. Fuel 80:1787–1797

Nagib S, Inoue K (2000) Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching. Hydrometallurgy 56:269–292

Nisbet IC, LaGoy PK (1992) Toxic equivalency factors (TEFs) for polycyclic aromatic hydrocarbons (PAHs). Regul Toxicol Pharmacol 16:290–300

Organisation for Economic Co-operation and Development (OECD) (1989) Economic instruments for environmental protection. OECD, Paris, pp 14

Ravindra K, Mittal AK, Van Grieken R (2001) Health risk assessment of urban suspended particulate matter with special reference to polycyclic aromatic hydrocarbons: a review. Rev Environ Health 16:169–189

Singh S, Prakash V (2007) The effect of temperature on PAHs emission from incineration of acrylic waste. Environ Monit Assess 127:73–77

Song G-J, Kim K-H, Seo Y-C, Kim S-C (2004) Characteristics of ashes from different locations at the MSW incinerator equipped with various air pollution control devices. Waste Manag 24:99–106

Sun P, Weavers LK, Taerakul P, Walker HW (2006) Characterization of polycyclic aromatic hydrocarbons (PAHs) on lime spray dryer (LSD) ash using different extraction methods. Chemosphere 62:265–274

Swedish EPA (2002) Assessment of contamination level. www.internat.naturvardsverket.se/

Tang XJ, Qiao JN, Chen C, Chen LT, Yu CN, Shen CF, Chen YX (2013) Bacterial communities of polychlorinated biphenyls polluted soil around an E-waste recycling workshop. Soil Sediment Contam Int J 55(5):562–573

Tian H, Gao J, Lu L, Zhao D, Cheng K, Qiu P (2012) Temporal trends and spatial variation characteristics of hazardous air pollutant emission inventory from municipal solid waste incineration in China. Environ Sci Technol 46:10364–10371

Tian H, Gao J, Hao J, Lu L, Zhu C, Qiu P (2013) Atmospheric pollution problems and control proposals associated with solid waste management in China: a review. J Hazard Mater 252:142–154

Tsai P-J, Shieh H-Y, Lee W-J, Lai S-O (2002) Characterization of PAHs in the atmosphere of carbon black manufacturing workplaces. J Hazard Mater 91:25–42

USEPA (2012) Mid-atlantic risk assessment screening level (SL) tables http://www.epa.gov/reg3hwmd/risk/human/rbconcentration_table/Generic_Tables/index.htm

Van Brummelen T, Verweij R, Wedzinga S, Van Gestel C (1996) Enrichment of polycyclic aromatic hydrocarbons in forest soils near a blast furnace plant. Chemosphere 32:293–314

Van Caneghem J, Block C, Van Brecht A, Wauters G, Vandecasteele C (2010) Mass balance for POPs in hazardous and municipal solid waste incinerators. Chemosphere 78:701–708

Van Caneghem J, Block C, Vandecasteele C (2014) Destruction and formation of dioxin-like PCBs in dedicated full scale waste incinerators. Chemosphere 94:42–47

Wang LC, Hsi HC, Wang YF, Lin SL, Chang-Chien GP (2010) Distribution of polybrominated diphenyl ethers (PBDEs) and polybrominated dibenzo-p-dioxins and dibenzofurans (PBDD/Fs) in municipal solid waste incinerators. Environ Pollut 158(5):1595–1602

Wey M-Y, Chao C-Y, Wei M-C, Yu L-J, Liu Z-S (2000) The influence of heavy metals on partitioning of PAHs during incineration. J Hazard Mater 77:77–87

Wheatley A, Sadhra S (2004) Polycyclic aromatic hydrocarbons in solid residues from waste incineration. Chemosphere 55:743–749

WHO (2000) Air quality guidelines for Europe, 2nd ed? WHO Regional Publications, European Series, no. 91. World Health Organization Regional Office for Europe, Copenhagen

Wild S, Mitcheill D, Yelland C, Jones K (1992) Municipal solid waste incinerator fly ash as a source of polynuclear aromatic hydrocarbons (PAHs) to the environment. Waste Manag Res 10:99–111

Wilson SC, Jones KC (1993) Bioremediation of soil contaminated with polynuclear aromatic hydrocarbons (PAHs): a review. Environ Pollut 81:229–249

World Health Organization (1985) Regional Office for Europe. Health Promotion Programme. Health promotion: a discussion document on the concept and principles. Health Promotion Programme, World Health Organization, Regional Office for Europe

Xu M, Yu D, Yao H, Liu X, Qiao Y (2011) Coal combustion-generated aerosols: formation and properties. Proc Combust Inst 33:1681–1697

Yan J-h, You X-f, Li X-d, Ni M-j, Yin X-f, Cen K-f (2004) Performance of PAHs emission from bituminous coal combustion. J Zhejiang Univ Sci 5:1554–1564

Yang H-H, Lai S-O, Hsieh L-T, Hsueh H-J, Chi T-W (2002) Profiles of PAH emission from steel and iron industries. Chemosphere 48:1061–1074

Yu D, Xu M, Yao H, Liu X, Zhou K, Li L, Wen C (2009) Mechanisms of the central mode particle formation during pulverized coal combustion. Proc Combust Inst 32:2075–2082

Zhang H, He P-J, Shao L-M (2008) Fate of heavy metals during municipal solid waste incineration in Shanghai. J Hazard Mater 156:365–373

Zhang DQ, Tan SK, Gersberg RM (2010) Municipal solid waste management in China: status, problems and challenges. J Environ Manag 91:1623–1633

Zhao Z-B, Liu K, Xie W, Pan W-P, Riley JT (2000) Soluble polycyclic aromatic hydrocarbons in raw coals. J Hazard Mater 73:77–85

Zhao L, Zhang F-S, Hao Z, Wang H (2008) Levels of polycyclic aromatic hydrocarbons in different types of hospital waste incinerator ashes. Sci Total Environ 397:24–30

Acknowledgments

This work was supported by the National Basic Research Program of China (973 Program, 2014CB238900), the National Natural Science Foundation of China (Nos. 41173032 and 41373110). We acknowledge editors and reviewers for polishing the language of the paper and for in-depth discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Liu, G. & Cao, Y. Levels and environmental impact of PAHs and trace element in fly ash from a miscellaneous solid waste by rotary kiln incinerator, China. Nat Hazards 76, 811–822 (2015). https://doi.org/10.1007/s11069-014-1520-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-014-1520-x