Abstract

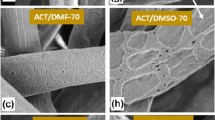

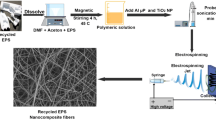

Electrospinning is used to prepare hydrophobic and self-cleaning polysulfone (PSf) surfaces. The effects of PSf concentration in Dimethylformamide (DMF) solvent and electrospinning process parameters on the surface structure and hydrophobicity are investigated. The experimental results show that depending on PSf concentration, three types of morphologies are obtained: beads, beads-on-strings, and free-beads fibers. The surface hydrophobicity depends mainly on the resultant surface morphology, and the existence of beads increases hydrophobicity. The contact angle (CA) is found to increase from 73° for smooth PSf surface to more than 160° for surfaces formed by electrospinning. Moreover, the contact angle hysteresis (CAH) was generally less than 10° for all the chemistries. It is noted that increasing the PSf concentration leads to the formation of beads-on-string and free-beads fiber structures; this morphological change is accompanied by a reduction in the contact angle. Surface structures are found to be more sensitive to electrospinning feed rate than to electrospinning voltage; however, these two parameters have a negligible influence on the hydrophobicity. Porosity measurements of different chemistries show an average pore size in the range 3–8 microns. The thickness of PSf mats was variable, from as low as 10 μm to as high as 70 μm.

Similar content being viewed by others

References

Zhang X, Shi F, Niu J, Jiang Y, Wang Z (2008) Superhydrophobic surfaces: from structural control to functional application. J Mater Chem 18:621–633

Zheng J, He A, Li J, Xu J, Han CC (2006) Studies on the controlled morphology and wettability of polystyrene surfaces by electrospinning or electrospraying. Polymer 47:7095–7102

Wang L, Yang S, Wang J, Wang C, Chen L (2011) Fabrication of superhydrophobic TPU film for oil–water separation based on electrospinning route. Mater Lett 65:869–872

Neinhuis C, Barthlott W (1997) Characterization and distribution of water-repellent, self-cleaning plant surfaces Ann. Bot 79:667–677

Zhan N, Li Y, Zhang C, Song Y, Wang H, Sun L, Yang Q, Hong X (2010) A novel multinozzle electrospinning process for preparing superhydrophobic PS films with controllable bead-on-string/microfiber morphology. J Colloid Interface Sci 345:491–495

Jiang L, Zhao Y, Zhai J (2004) A Lotus-Leaf-like Superhydrophobic Surface: A Porous Microsphere/Nanofiber Composite Film Prepared by Electrohydrodynamics. Angew Chem Int Ed 43:4338–4341

Chen Y, Kim H (2009) Preparation of superhydrophobic membranes by electrospinning of fluorinated silane functionalized poly(vinylidene fluoride). Appl Surf Sci 255:7073–7077

Lim J-M, Yi G-R, Moon JH, Heo C-J, Yang S-M (2007) Superhydrophobic Films of Electrospun Fibers with Multiple-Scale Surface Morphology. Langmuir 23:7981–7989

Wang H-S, Fu G-D, Li X-S (2009) Functional Polymeric Nanofibers from Electrospinning. Recent Pat Nanotechnol 3:21–31

Zhang L, Liu L, Pan FL, Wang D, Pan Z, Effects of Heat Treatment on the Morphology and Performance of PSf Electrospun Nanofibrous Membrane, J. Engr. Fibers & Fabrics 16, SPECIAL ISSUE - July 2012

Khan Z, Kafiah FM (2013) “Preparation of Polysulfone Electrospun Nanofibers: Effect of Electrospinning and Solution Parameters”, Conference on Membrane Science & Technology MST, Aug. 27–29, Kaula Lumpur, Malaysia

Jalili R, Hosseini SA, Morshed M (2005) The Effects of Operating Parameters on the Morphology of Electrospun Polyacrilonitrile Nanofibres. Iran Polym J 14:1074

Fong H, Chun I, Reneker DH (1999) Beaded nanofibers formed during electrospinning. Polymer 40:4585

Chang KH, Lin HL (2009) Nano hydroxyapatite–polysulfone coating on Ti-6Al-4V substrate by electrospinning. J Polym Res 16:611

Dhakate SR, Singla B, Uppal M, Mathur RB (2010) Effect of Processing Parameters on Morphology and Thermal Properties Of Electrospun Polycarbonate Nanofibers. Adv Mat Lett 1:200

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

K. Acatay, E. Simsek, C.O.-Yang, Y.Z. Menceloglu, Tunable superhydrophobically stable polymeric surfaces by electrospinning, Angew. Chem. Int. Ed. 43 (2004) 5210–5213

Chen W, Fadeev AY, Hsieh MC, Oner D, Youngblood J, McCarthy TJ (1999) Ultrahydrophobic and Ultralyophobic Surfaces: Some Comments and Examples. Langmuir 15(10):3395–3399

Öner D, McCarthy TJ (2000) Ultrahydrophobic Surfaces. Effects of Topography Length Scales on Wettability. Langmuir 16(20):7777–7782

Yabu H, Shimomura M (2005) Single-Step Fabrication of Transparent Superhydrophobic Porous Polymer Films. Chem Mater 17:5231

Gu G, Dang H, Zhang Z, Wu Z (2006) Fabrication and characterization of transparent superhydrophobic thin films based on silica nanoparticles. Appl Phys A 83:131

Hozumi A, Takai O (1998) Preparation of silicon oxide films having a water-repellent layer by multiple-step microwave plasma-enhanced chemical vapor deposition. Thin Solid Films 334:54

Feng L, Zhang Y, Xi J, Zhu Y, Wang N, Xia F, Jiang L (2008) Petal effect: A superhydrophobic state with high adhesive force. Langmuir 24:4114

Duparré A, Flemming M, Steinert J, Reihs K (2002) Optical coatings with enhanced roughness for ultrahydrophobic, low-scatter applications, Appl. Opt. 41 3294

Tadanaga K, Kitamuro K, Matsuda A, Minami TJ (2003) Formation of Superhydrophobic Alumina Coating Films with High Transparency on Polymer Substrates by the Sol–gel Method, Sol–Gel Sci. Technol 26:705

Rao AV, Latthe SS, Nadargi DY, Hirashima H, Ganesan V (2009) Preparation of MTMS based superhydrophobic silica films by sol–gel method. J Colloid Interface Sci 332:484

Quere D, Lafuma A, Bico J (2003) Slippy and sticky microtextured solids. Nanotechnology 14:1109

Lafuma A, Quere D (2003) Superhydrophobic states. Nat Mater 2:457

Acknowledgments

The authors acknowledge the financial support of King Fahd University of Petroleum and Minerals (KFUPM) through KFUPM-MIT Project No. R16-DMN-11, and King Abdulaziz City for Science and Technology (KACST) through Project No. 11-ADV2134-04. In addition, the following personnel at KFUPM are acknowledged for their assistance with specimen preparation and characterization: Feras Kafiah for sample preparation, Prof Tahar Laoui (ME dept.) for permission to use his Nanotechnology Lab and relevant consumables, and Faheem Patel for assisting with the porosity measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Qadhi, M., Merah, N., Matin, A. et al. Preparation of superhydrophobic and self-cleaning polysulfone non-wovens by electrospinning: influence of process parameters on morphology and hydrophobicity. J Polym Res 22, 207 (2015). https://doi.org/10.1007/s10965-015-0844-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0844-x