Abstract

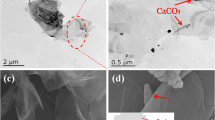

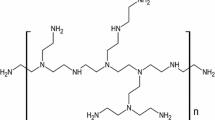

Graphene nanoplatelets (GNPs) are an attractive additive for polymers to provide electrical conductivity to a composite. If the GNP surface and the polymer are incompatible, the interfaces are weak, resulting in a large drop in the flexural strength and toughness of the composite compared to the native polymer. In the present study, we show that adding core–shell rubbery (CSR) nanoparticles, that have a polyisobutadiene (PIB) core and a thin, polystyrene (PS) compatible shell, to a PS–GNP composite enhances the dispersion of the GNP and suppresses their restacking, increasing the electrical conductivity of the composite by several orders of magnitude. In addition, there is complete recovery of the flexural strength and a large increase in toughness compared to PS samples without fillers. The recovery of the mechanical properties is related to a uniform distribution of the CSR and good binding at the interfaces because of the compatibility of the filler surface with the PS matrix, as well as the rubbery nature of the PIB core. This strategy of using a second filler as both a toughening agent as well as a dispersion aid breaks a commonly encountered tradeoff between electrical and mechanical property enhancement by fillers. It can be deployed for applications where both a high electrical conductivity and excellent mechanical properties of polymer composites are desired.

Similar content being viewed by others

References

Geim AK (2009) Graphene: Status and Prospects. Science 324:1530–1534

Geim AK, Novoselov KS (2007) The Rise of Graphene. Nat Mater 6:183–191

Rao CNR, Sood AK, Voggu R, Subrahmanyam KS (2010) Some Novel Attributes of Graphene. J Phys Chem Lett 1(2):572–580

Kytopoulos VN (2013) The elastic modulus and the thermal expansion coefficient in particulate composites by a hexaphase model. J Reinf Plast Compos 32:499–510

Nair ABG (2014) N., Joseph, R. Non-linear Viscoelastic Behaviour of Rubber-Rubber Blend Composites and Nanocomposites: effect of Spherical, Layered and Tubular Fillers. Adv Polym Sci 264:85–134

Zhang Z, Tan Y, Wang X, Tan H, Li J (2015) Mechanical behavior and fracture toughness of epoxy composites reinforced with combination of fibrous and spherical nanofillers. Polym Compos 36:2147–2156

Kim H, Abdala A, Macosko CW (2010) Graphene/Polymer Nanocomposites. Macromolecules 43:6515–6530

Kuilla T, Bhadra S, Yao D, Kim NH, Bose S, Lee JH (2010) Recent advances in graphene based polymer composites. Prog Polym Sci 35(11):1350–1375

Verdejo R, Bernal MM, Romasanta LJ, Lopez-Manchado MA (2011) Graphene Filled Polymer Nanocomposites. J Mater Chem 21:3301–3310. doi:10.1039/C0JM02708A

Singh V, Joung D, Zhai L, Das S, Khondaker SI, Seal S (2011) Graphene based materials: past, present and future. Prog Mater Sci 56(8):1178–1271

Stankovich S, Dikin DA, Dommett GHB, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Nguyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442(7100):282–286

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52(1):5–25

Wang ZP, Nelson JK, Miao JJ, Linhardt RJ, Schadler LS, Hillborg H, Zhao S (2012) Effect of High Aspect Ratio Filler on Dielectric Properties of Polymer Composites: a Study on Barium Titanate Fibers and Graphene Platelets. Ieee T Dielect El In 19(3):960–967

Chakraborty I, Bodurtha KJ, Heeder NJ, Godfrin MP, Tripathi A, Hurt RH, Shukla A, Bose A (2014) Massive Electrical Conductivity Enhancement of Multilayer Graphene/Polystyrene Composites Using a Nonconductive Filler. ACS Appl Mater Inter 6(19):16472–16475

Rafiee MA, Rafiee J, Wang Z, Song H, Yu Z-Z, Koratkar N (2009) Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 3:3884–3890

Zaeri MM, Ziaei-Rad S, Vahedi A, Karimzadeh F (2010) Mechanical modelling of carbon nanomaterials from nanotubes to buckypaper. Carbon 48(13):3916–3930

Rahman R (2013) The role of graphene in enhancing the stiffness of polymeric material: a molecular modeling approach. J Appl Phys 113(24):243503

Martin-Gallego M, Bernal MM, Hernandez M, Verdejo R, Lopez-Manchado MA (2013) Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur Polym J 49(6):1347–1353

Li WK, Dichiara A, Bai JB (2013) Carbon nanotube-graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos Sci Technol 74:221–227

Kuvardina EV, Novokshonova LA, Lomakin SM, Timan SA, Tchmutin IA (2013) Effect of the graphite nanoplatelet size on the mechanical, thermal, and electrical properties of polypropylene/exfoliated graphite nanocomposites. J Appl Polym Sci 128(3):1417–1424

Khan U, O’Connor I, Gun’ko YK, Coleman JN (2010) The preparation of hybrid films of carbon nanotubes and nano-graphite/graphene with excellent mechanical and electrical properties. Carbon 48(10):2825–2830

Chen P, Wang Y, Wei T, Meng Z, Jia X, Xi K (2013) Greatly enhanced mechanical properties and heat distortion resistance of poly(l-lactic acid) upon compositing with functionalized reduced graphene oxide. J Mater Chem A 1(32):9028–9032. doi:10.1039/C3TA12060K

Satti A, Larpent P, Gun’ko Y (2010) Improvement of mechanical properties of graphene oxide/poly(allylamine) composites by chemical crosslinking. Carbon 48(12):3376–3381

Sengupta R, Bhattacharya M, Bandyopadhyay S, Bhowmick AK (2011) A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog Polym Sci 36(5):638–670

Ruoff RS (2009) Graphene-based materials. Abstracts of Papers, 237th ACS National Meeting, Salt Lake City, UT, United States, March 22-26, 2009 PMSE-011

Gouda PSS, Kulkarni R, Kurbet SN, Jawali D (2013) Effects of multi walled carbon nanotubes and graphene on the mechanical properties of hybrid polymer composites. Adv Mater Lett 4(4):261–270 10 pp

Dai J, Lang M (2012) Preparation and mechanical properties of graphene oxide/PMMA and surface-functionalized graphene/PMMA composites. Huaxue Xuebao 70(11):1237–1244

Layek RK, Das AK, Park MJ, Kim NH, Lee JH (2015) Enhancement of physical, mechanical, and gas barrier properties in noncovalently functionalized graphene oxide/poly(vinylidene fluoride) composites. Carbon 81:329–338

Kuila T, Khanra P, Mishra AK, Kim NH, Lee JH (2012) Functionalized-graphene/ethylene vinyl acetate co-polymer composites for improved mechanical and thermal properties. Polym Test 31(2):282–289

Yan N, Buonocore G, Lavorgna M, Kaciulis S, Balijepalli SK, Zhan Y, Xia H, Ambrosio L (2014) The role of reduced graphene oxide on chemical, mechanical and barrier properties of natural rubber composites. Compos Sci Technol 102:74–81

Qi X-Y, Yan D, Jiang Z-G, Cao Y-K, Yu Z-Z, Yavari F, Koratkar N (2011) Enhanced Electrical Conductivity in Polystyrene Nanocomposites at Ultra-Low Graphene Content. ACS Appl Mater Inter 3(8):3130–3133

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26:98–100

Parameswaran V, Shukla A (2000) Processing and Characterization of a Model Functionally Gradient Material. J Mater Sci 30:21–29. doi:10.1023/A:1004767910762

Acknowledgements

We acknowledge support from the Rhode Island Science and Technology Advisory Council.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chakraborty, I., Shukla, A. & Bose, A. Core–shell rubbery fillers for massive electrical conductivity enhancement and toughening of polystyrene–graphene nanoplatelet composites. J Mater Sci 51, 10555–10560 (2016). https://doi.org/10.1007/s10853-016-0275-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0275-z