Abstract

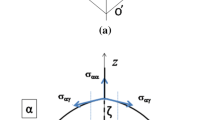

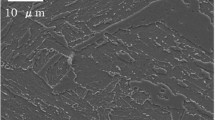

The growth of austenite from martensite or carbon-supersaturated ferrite matrix during continuous heating, which accompanies carbon diffusion in the growing austenite, was studied by DICTRA and linearized gradient approximation extended to include soft impingement of diffusion fields in the matrix. While the austenite growth is controlled by carbon diffusion in ferrite at an early stage, it is controlled by diffusion in austenite at the intermediate and late stages. At a low heating rate, the austenite-finish temperature Af is almost equal to the Ae3 temperature of the alloy, whereas at a high heating rate, Af exceeds the Ae3 to a progressively larger extent with the increasing heating rate and matrix grain size. At a very high heating rate, i.e., 105–106 °C/s, the mobility of α/γ interface is likely to have a significant influence on the growth of austenite, and the untransformed ferrite matrix is transformed in a massive mode. These results are in accordance with the earlier observation of austenite formation during rapid heating in a low carbon iron alloy.

Similar content being viewed by others

References

Takechi H (2008) Transformation hardenability of steel sheet for automotive applications. JOM 60:22–26

Speich GR, Demarest VA, Miller RL (1981) Formation of austenite during intercritical annealing of dual-phase steels. Metall Trans A 12A:1419–1428

Nehrenberg AE (1950) The growth of austenite as related to prior structure. Trans AIME 188:162–188

Zener C (1949) Theory of growth of spherical precipitates from solid solution. J Appl Phys 20:950–953

Hillert M (1975) Diffusion and interface control of reactions in alloys. Metall Trans A 6A:5–19

Hillert M, Höglund L (2006) Mobility of & ∝/γ/phase interfaces in Fe alloys. Scr Mater 54:1259–1263

Gamsjäger E, Militzer M, Fazeli F, Svoboda J, Fisher FD (2006) Interface mobility in case of the austenite-to-ferrite phase transformation. Comput Mater Sci 37:94–100

Enomoto M, Aaronson HI (1980) On the linearized gradient approximation for diffusion-limited growth of a spherical precipitate. J Appl Phys 51:818–819

Jönsson B (1993) Trita-Mac-0514. Royal Institute of Technology, Stockholm 1993

Ågren J (1986) A Revised expression for the diffusivity of carbon in binary Fe-C austenite. Scr Metall. 20:1507–1510

Chen H, Van der Zwaag S (2011) Modeling of soft impingement effect during solid-state partitioning phase transformations in binary alloys. J Mater Sci 46:1328–1336. doi:10.1007/s10853-010-4922-5

Ridley N, Stuart H (1970) Partial molar volumes from high-temperature lattice parameters of iron-carbon austenites. Met Sci. 4:219–222

Sietsma J, Van der Zwaag S (2004) A concise model for mixed-mode phase transformations in the solid state. Acta Mater 52:4143–4152

Faires JD, Burdedn RL (1993) Numerical methods. PWS-KENT, Boston 5

Speich GR, Szirmae A (1969) Formation of austenite from ferrite and ferrite-carbide aggregates. Trans TMS AIME 245:1063–1074

Enomoto M (2002) Simulation of ferrite growth in continuously cooled low-carbon iron alloys. Metall Mater Trans A 33A:2309–2316

Moszner F, Povoden-Karadeniz E, Pogatscher S, Uggowitzer PJ, Estrin Y, Gerstl SSA, Kozeschnik E, Löffler JF (2014) Reverse α′→γ transformation mechanisms of martensitic Fe-Mn and age-hardenable Fe-Mn-Pd alloys upon fast and slow continuous heating. Acta Mater 72:99–109

Wits JJ, Kop TA, Van Leeuwen Y, Sietsma J, Van der Zwaag S (2000) A study on the austenite-to-ferrite phase transformation in binary substitutional iron alloys. Mater Sci Eng A283:234–241

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Enomoto, M., Hayashi, K. Simulation of the growth of austenite during continuous heating in low carbon iron alloys. J Mater Sci 50, 6786–6793 (2015). https://doi.org/10.1007/s10853-015-9234-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9234-3