Abstract

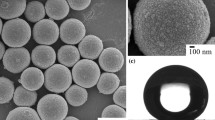

In this article, we demonstrate a newly developed technique for generation of nanoporous polymer materials. Generally, the production processes of polymeric nanostructured materials require high pressure due to the handling of gaseous blowing agents. Our new approach allows to generate nanoporous polymer materials without blowing agent at ambient conditions. Starting from a crosslinked polymer gel swollen with a mixture of at least two specially selected solvents leads to a nanoporous material by sequential evaporation. We varied the pore size of the generated structures between 80 and 800 nm so that the effect of the pore size on the gaseous thermal conductivity could be analyzed. Decreasing the pore size of the materials, the gaseous thermal conductivity could be reduced considerably. Thus, we developed a blowing agent free technique which allows the generation of nanoporous polymer materials—Knudsen materials—at an ambient pressure.

Left: Process of generating a nanoporous polymer by swelling and subsequent evaporation of a polymer with a mixture of a solvent and a non-solvent, right: gaseous thermal conductivity of the generated materials as function of pressure giving proof that our materials are Knudsen materials.

Similar content being viewed by others

References

Jelle BP, Gustavsen A, Baetens R (2010) The path to the high performance thermal building insulation materials and solutions of tomorrow. J Build Phys 34:99–123. doi:10.1177/1744259110372782

Knudsen M (1909) Eine Revision der Gleichgewichtsbedingung der Gase - Thermische Molekularströmung. Ann Phys 336:205–229

Kennard EH (1938) Kinetic theory of gases with an introduction to statistical mechanics. Mc Graw Hill, New York

Lemmon EW, Jacobsen RT (2004) Viscosity and thermal conductivity equations for nitrogen, oxygen, argon, and air. Int J Thermophys 25:21–69. doi:10.1023/B:IJOT.0000022327.04529.f3

Jelle BP (2011) Traditional, state-of-the-art and future thermal building insulation materials and solutions—properties, requirements and possibilities. Energy and Buildings 43:2549–2563. doi:10.1016/j.enbuild.2011.05.015

Jelle BP, Gustavsen A, Baetens R (2012) Innovative high performance thermal building insulation materials - Todays state-of-the-art and beyond tomorrow. Proceedings of the Building Enclosure Science & Technology 2

Jelle BP, Kalnæs SE, Gao T (2015) Low-emissivity materials for building applications: a state-of-the-art review and future research perspectives. Energy and Buildings 96:329–356. doi:10.1016/j.enbuild.2015.03.024

Ihara T, Grynning S, Gao T, et al. (2014) Impact of convection on thermal performance of aerogel granulate glazing systems. Energy and Buildings 88:165–173. doi:10.1016/j.enbuild.2014.12.001

Berge A, Johansson P (2012) Literature review of high performance thermal insulation. Building Physics 2:40

Kistler S (1931) Coherent expanded aerogels and jellies. Nature 127:741

Kistler S (1932) Coherent expanded aerogels. J Chem Phys 36:52–64

Pekala RW (1989) Organic aerogels from the polycondensation of resorcinol with formaldehyde. J Mater Sci 24:3221–3227. doi:10.1007/BF01139044

Wen J, Wilkes GL (1996) Organic/inorganic hybrid network materials by the sol−gel approach. Chem Mater 8:1667–1681. doi:10.1021/cm9601143

Schwan M, Ratke L (2013) Flexibilisation of resorcinol–formaldehyde aerogels. J Mater Chem A 1:13462. doi:10.1039/c3ta13172f

Fricke J, Tillotson TM (1997) Aerogels: production, characterization, and applications. Thin Solid Films 297:212–223. doi:10.1016/S0040-6090(96)09441-2

Mulik S, Sotiriou-Leventis C (2011) Aerogels Handbook. doi: 10.1007/978–1–4419-7589-8_1

Lu X, Caps R, Fricke J, et al. (1995) Correlation between structure and thermal conductivity of organic aerogels. J Non-Cryst Solids 188:226–234. doi:10.1016/0022-3093(95)00191-3

Mu D, Liu ZS, Huang C, Djilali N (2008) Determination of the effective diffusion coefficient in porous media including Knudsen effects. Microfluid Nanofluid 4:257–260

Nait-ali B, Haberko K, Vesteghem H, et al. (2006) Thermal conductivity of highly porous zirconia. J Eur Ceram Soc 26:3567–3574. doi:10.1016/j.jeurceramsoc.2005.11.011

Reichenauer G, Heinemann U, Ebert H (2007) Relationship between pore size and the gas pressure dependence of the gaseous thermal conductivity. Colloids and Surfaces A: Physicochem Eng Aspects 300:204–210. doi:10.1016/j.colsurfa.2007.01.020

Lee OJ, Lee KH, Yim TJ, Yoo KP (2002) Determination of mesopore size of aerogels from thermal conductivity measurements. J Non-Cryst Solids 298:287–292

Notario B, Pinto J, Solorzano E, et al. (2015) Experimental validation of the Knudsen effect in nanocellular polymeric foams. Polymer 56:57–67. doi:10.1016/j.polymer.2014.10.006

Kaiser W (2007) Kunststoffe für Ingenieure. Hanser Verlag, ISBN:3446430474

Rossmy G (1968) Foaming process for polyurethane in the presence of pore regulators

Rossmy GR, Kollmeier HJ, Lidy W, et al. (1977) Cell-opening in one-shot flexible polyether based polyurethane foams. The Role of Silicone Surfactant and its Foundation in the Chemistry of Foam Formation. Journal of Cellular Plastics 13:26–35. doi:10.1177/0021955X7701300102

Saechtling H (1995) Kunststoff Taschenbuch. Carl Hanser Verlag, ISBN:978–3446403529

Uhlig K (2001) Polyurethan Taschenbuch. Carl Hanser Verlag, ISBN: 3–446–40307-8

Park CB, Behravesh AH, Venter RD (1998) Low density microcellular foam processing in extrusion using CO2. Polym Eng Sci 38:1812–1823

Baldwin DF (1996) An extrusion system for the processing of microcellular polymer sheets: shaping and cell growth control. Polym Eng Sci 36:1425–1435. doi:10.1002/pen.10537

Baldwin DF, George T, Woodru W, et al. (1998) Microcellular sheet extrusion system process design models for shaping and cell growth control. Polym Eng Sci 38:674–688

Kiran E (2010) Foaming strategies for bioabsorbable polymers in supercritical fluid mixtures. Part II. Foaming of poly(caprolactone-co-lactide) in carbon dioxide and carbon dioxide + acetone fluid mixtures and formation of tubular foams via solution extrusion. J Supercrit Fluids 54:308–319. doi:10.1016/j.supflu.2010.05.004

Kiran E (2010) Foaming strategies for bioabsorbable polymers in supercritical fluid mixtures. Part I. Miscibility and foaming of poly(L-lactic acid) in carbon dioxide + acetone binary fluid mixtures. J Supercrit Fluids 54:296–307

Marrazzo C, Maio ED, Iannace S (2007) Foaming of synthetic and natural biodegradable polymers. J Cell Plast 43:123–133. doi:10.1177/0021955X06073214

Handa YP, Zhang Z (2000) A new technique for measuring retrograde Vitrification in polymer–gas systems and for making Ultramicrocellular. J Polym Sci B Polym Phys 38:716–725

Colton JS, Suh NP (1987) Nucleation of microcellular foam: theory and practice. Polym Eng Sci 27:500–503

Colton JS, Suh NP (1987) Nucleation of microcellular thermoplastic foam with additives: part I: theoretical considerations. Polym Eng Sci 27:485–492. doi:10.1002/pen.760270702

Goel SK, Beckman EJ (1994) Generation of microcellular polymeric foams using supercritical carbon dioxide. II: Cell growth and skin formation Polymer Engineering & Science 34:1148–1156. doi:10.1002/pen.760341408

Satish K, Eric J, Goel SK, Beckman EJ (1994) Generation of microcellular polymeric foams using supercritical carbon dioxid. II: cell growth and skin formation. Polym Eng Sci 34:1148–1156

Martini-Vvedensky JE, Suh NP, Waldman FA (1982) Microcellular closed cell foams and their method of manufacture

Krause B (2001) Polymer nanofoams. PrintPartners Ipskamp B.V., ISBN:9036516471, Twente

Krause B, Sijbesma HJP, Mu P (2001) Bicontinuous nanoporous polymers by carbon dioxide foaming. Macromolecules 34:8792–8801

Krause B, Mettinkhof R, Van Der Vegt NFA, Wessling M (2001) Microcellular foaming of amorphous high-Tg polymers using carbon dioxide. Macromolecules 34:874–884

Krause B, Diekmann K, van der Vegt NF a, Wessling M (2002) Open nanoporous morphologies from polymeric blends by carbon dioxide foaming. Macromolecules 35:1738–1745. doi:10.1021/ma011672s

Siripurapu S, Coughlan J a, Spontak RJ, Khan S a (2004) Surface-constrained foaming of polymer thin films with supercritical carbon dioxide. Macromolecules 37:9872–9879. doi:10.1021/ma0484983

Zhang H, Cooper AI (2002) Synthesis of Monodisperse emulsion-Templated polymer beads by oil-in-water-in-oil (O/W/O) sedimentation polymerization. Chem Mater 14:4017–4020

Butler R, Hopkinson I, Cooper I (2003) Synthesis of porous emulsion-templated polymers using high internal phase CO2-in-water emulsions. Journal of the American Chemical Society 14473–14481

Butler R, Davies CM, Cooper I (2001) Emulsion Templating using high internal phase supercritical fluid emulsions. Adv Mater 13:1459–1463

Cooper AI (2003) Porous materials and supercritical fluids. Adv Mater 15:1049–1059. doi:10.1002/adma.200300380

Strey R, Sottmann T, Schwan M (2008) Aufgeschäumtes Material und Herstellungsverfahren für das aufgeschäumte Material. doi: No. DE10260815B4

Schwan M, Kramer L, Sottmann T, Strey R (2010) Phase behaviour of propane- and SCCO2-microemulsions and their prominent role for the recently proposed foaming procedure POSME (Principle of Supercritical Microemulsion Expansion). Phys Chem Chem Phys 12:6247–6252

Strey R, Müller A (2010) Erzeugung nanodisperser Einschlüsse in einer hochviskosen Matrix. DE102010053064A1

Müller A (2013) Preperation of polymer nano-foams: templates, challenges, and kinetics. (PhD-Thesis, University of Cologne), Cuvillier Verlag, ISBN:978–3–95404-566-2, Cologne

Strey R, Oberhoffer R, Müller A (2015) Herstellung von porösen Materialien durch Expansion von Polymergelen. DE102013223391A1

Oberhoffer R (2015) Nachhaltige Erzeugung von mikro- und nanoporösen Materialien mit nahekritischem CO2. (PhD-Thesis, University of Cologne), Cuvillier Verlag, ISBN:978–3–7369-9044-9

Daoud M, Bouchaud E, Jannink G (1986) Swelling of polymer gels. Macromolecules 19:1955–1960

Tanaka T, Fillmore DJ (1979) Kinetics of swelling of gels kinetics of swelling of gels. J Chem Phys 70:1214–1218. doi:10.1063/1.437602

Flory P, Rehner J (1943) Statistical machanics of cross-linked polymer networks. II. Swelling. J Chem Phys 11:521–526

Tipler PA, Mosca G (2015) Physik für Wissenschaftler und Ingenieure, 7. Edition. Wagner, J., Springer, ISBN:978–3–642-54165-0

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Funding

Funding was done completely based on our inhouse budget.

Rights and permissions

About this article

Cite this article

Grassberger, L., Koch, K., Oberhoffer, R. et al. Blowing agent free generation of nanoporous poly(methylmethacrylate) materials. Colloid Polym Sci 295, 379–389 (2017). https://doi.org/10.1007/s00396-017-4012-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4012-1