Abstract

In-reactor blends of polypropylene/poly(ethylene-co-propylene) with complex microstructure, synthesized through different polymerization procedures; two-step (one homopolymerization and one copolymerization under high ethylene concentration) and three-step (with an additional copolymerization step under low ethylene concentration), were characterized by rheological measurements. The effects of a change in the polymerization process on the types and amounts of block copolymers in the blends were evaluated using small amplitude oscillation rheometry in the linear viscoelastic region. The Palierne model in its complete form was employed to model the rheological behavior of the blends. For this analysis the reactor products were separated into xylene cold insoluble (XCI) and xylene cold soluble fractions. Besides, another two copolymer fractions at 80 and 100 °C, which are crystallizable copolymer fractions and contain block copolymers rich in polyethylene and polypropylene, respectively, were separated from XCI fraction by xylene using temperature gradient elution fractionation method. Considering all copolymer fractions as dispersed and the remained fraction (mostly polypropylene) as matrix phase, it was shown that the rheological properties of the blends could not be predicted by Palierne model. It was found that only by considering part of block copolymer fractions having long polypropylene sequences along with polypropylene homopolymer as one phase, the rheological properties of the blends could be predicted by Palierne model. By rheological modeling, it was confirmed that the amounts of copolymers with long polypropylene sequences which are miscible with the matrix are higher in the case of three-step blends and also the elasticity of three-step polymerized blends is higher than two-step polymerized blends.

Similar content being viewed by others

References

Liu G, Qiu G (2013) Study on the mechanical and morphological properties of toughened polypropylene blends for automobile bumpers. Polym Bull 70(3):849–857. doi:10.1007/s00289-012-0880-1

Yokoyama Y, Ricco T (1998) Toughening of polypropylene by different elastomeric systems. Polymer 39(16):3675–3681. doi:10.1016/s0032-3861(97)10358-5

Galli P, Vecellio G (2001) Technology: driving force behind innovation and growth of polyolefins. Prog Polym Sci 26:1287–1336. doi:10.1016/S0079-6700(01)00029-6

Chen Y, Chen Y, Chen W, Yang D (2008) Multilayered core–shell structure of the dispersed phase in high-impact polypropylene. J Appl Polym Sci 108:2379–2385. doi:10.1002/app.25410

Zhang C, Shangguan Y, Chen R, Zheng Q (2011) Study on thermal behavior of impact polypropylene copolymer and its fractions. J Appl Polym Sci 119(3):1560–1566. doi:10.1002/app.32827

Cai H, Luo X, Ma D, Wang J, Tan H (1999) Structure and properties of impact copolymer polypropylene. I. Chain structure. J Appl Polym Sci 71(1):93–101. doi:10.1002/(sici)1097-4628(19990103)71:1<93:aid-app12>3.0.co;2-t

Tong C, Lan Y, Chen Y, Chen Y, Yang D, Yang X (2012) The functions of crystallizable ethylene–propylene copolymers in the formation of multiple phase morphology of high impact polypropylene. J Appl Polym Sci 123(3):1302–1309. doi:10.1002/app.34609

Flaris V, Stachurski ZH (1992) The mechanical-behavior of blends of polyethylene, polypropylene, and an ethylene–propylene block copolymer at −20 °C. J Appl Polym Sci 45:1789–1798. doi:10.1002/app.1992.070451013

Liu YL, Xu JT, Dong Q, Fu ZS, Fan ZQ (2009) Crystallization behavior of the blends of isotactic polypropylene and ethylene–propylene blocky copolymers. Polym Plast Technol Eng 48(4):333–341. doi:10.1080/03602550802675975

Zhang C, Shangguan Y, Chen R, Wu Y, Chen F, Zheng Q, Hu G (2010) Morphology, microstructure and compatibility of impact polypropylene copolymer. Polymer 51(21):4969–4977. doi:10.1016/j.polymer.2010.08.021

Appleby T, Cser F, Moad G, Rizzardo E, Stavropoulos C (1994) Compatibilisation of polystyrene–polyolefin blends. Polym Bull 32(4):479–485. doi:10.1007/BF00587891

Taheri M, Morshedian J, Khonakdar HA (2011) Effect of compatibilizer on interfacial tension of SAN/EPDM blend as measured via relaxation spectrums calculated from Palierne and Choi–Schowalter models. Polym Bull 66(3):363–376. doi:10.1007/s00289-010-0336-4

Bagheri H, Jahani Y, Nekoomanesh Haghighi M, Hakim S, Fan ZQ (2011) Dynamic shear rheological behavior of PP/EPR in-reactor alloys synthesized by multi-stage sequential polymerization process. J Appl Polym Sci 120(6):3635–3641. doi:10.1002/app.33566

Vincze-Minya KA, Schausberger A (2007) Characterization of phase morphology of polymer melts (PP/PE blends) via rheology. J Appl Polym Sci 105(4):2294–2298. doi:10.1002/app.26269

Choi SJ, Schowalter WR (1975) Rheological properties of nondilute suspensions of deformable particles. Phys Fluids 18:420–427. doi:10.1063/1.861167

Bousmina M (1999) Rheology of polymer blends: linear model for viscoelastic emulsions. Rheol Acta 38(1):73–83. doi:10.1007/s003970050157

Yu W, Bousmina M, Grmela M (2002) Modeling of oscillatory shear flow of emulsions under small and large deformation fields. J Rheol 46(6):1401–1418. doi:10.1122/1.157303

Yu W, Bousmina M, Grmela M, Palierne JF, zhou C (2002) Quantitative relationship between rheology and morphology in emulsions. J Rheol 46(6):1381–1399. doi:10.1122/1.1517302

Bousmina M, Yu W (2003) Ellipsoidal model for droplet deformation in emulsions. J Rheol 47(4):1011–1039. doi:10.1122/1.1582853

Palierne JF (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta 29:204–214. doi:10.1007/BF01331356

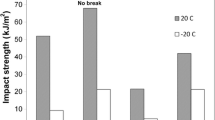

Moballegh L, Hakim S, Morshedian J, Nekoomanesh M (2015) A new approach to increase toughness of synthesized PP/EPR in-reactor blends by introducing a copolymerization step under low ethylene concentration. J Polym Res 22(5):1–11. doi:10.1007/s10965-015-0709-3

Kamdar AR, Hu YS, Ansems P, Chum SP, Hiltner A, Baer E (2006) Miscibility of propylene–ethylene copolymer blends. Macromolecules 39:1496–1506. doi:10.1021/ma052214c

Nitta KH, Shin YW, Hashiguchi H, Tanimoto S, Terano M (2005) Morphology and mechanical properties in the binary blends of isotactic polypropylene and novel propylene-co-olefin random copolymers with isotactic propylene sequence 1. Ethylene–propylene copolymers. Polymer 46:965–975. doi:10.1016/j.polymer.2004.11.033

de Goede E, Mallon P, Pasch H (2010) Fractionation and analysis of an impact poly(propylene) copolymer by TREF and SEC-FTIR. Macromol Mater Eng 295:366–373. doi:10.1002/mame.200900336

Tan H, Li L, Chen Z, Song Y, Zheng Q (2005) Phase morphology and impact toughness of impact polypropylene copolymer. Polymer 46(10):3522–3527. doi:10.1016/j.polymer.2005.02.088

Pires M, Mauler RS, Liberman SA (2004) Structural characterization of reactor blends of polypropylene and ethylene–propylene rubber. J Appl Polym Sci 92(4):2155–2162. doi:10.1002/app.20193

Kossuth M, Morse D, Bates F (1999) Viscoelastic behavior of cubic phases in block copolymer melts. J Rheol 43:167–196. doi:10.1122/1.550981

Riemann RE, Cantow HJ, Friedrich C (1996) Rheological investigation of form relaxation and interface relaxation processes in polymer blends. Polym Bull 36(5):637–643. doi:10.1007/bf00342457

Riemann RE, Cantow HJ, Friedrich C (1997) Interpretation of a new interface-governed relaxation process in compatibilized polymer blends. Macromolecules 30(18):5476–5484. doi:10.1021/ma961814w

Mighri F, Huneault MA, Ajji A, Ko GH, Watanabe F (2001) Rheology of EPR/PP blends. J Appl Polym Sci 82(9):2113–2127. doi:10.1002/app.2057

Fahrländer M, Friedrich C (1999) Rheological properties of polymer blends with sphere-in-sphere morphology. Rheol Acta 38(3):206–213. doi:10.1007/s003970050170

Xu L-Q, Huang H-X, Chen Z-K, Wu X-J (2014) Effects of emulsion parameters on relaxation behaviors for immiscible polymer blends. J Appl Polym Sci 131(1):39690–39706. doi:10.1002/app.39690

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moballegh, L., Hakim, S., Morshedian, J. et al. Rheological characterization of polypropylene/poly(ethylene-co-propylene) in-reactor blends synthesized under different polymerization conditions. Polym. Bull. 74, 1045–1060 (2017). https://doi.org/10.1007/s00289-016-1762-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1762-8