Abstract

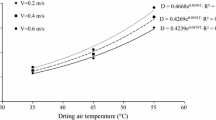

Drying of apple pomace representing by-products from apple juice processing was studied. The results obtained show that moisture content of the pomace decreases with time and temperature. The Midilli et al. model was selected as the best mathematical model for describing the drying kinetics of the apple pomace. The effective moisture diffusivity varied from 1.73 × 10−10 to 4.40 × 10−10 m2/s and the activation energy was calculated to be 29.65 kJ/mol.

Similar content being viewed by others

References

FAO (2013) http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor. Updated: August 08, 2013

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 43:1233–1238

Bosse AK, Fraatz MA, Zorn H (2013) Formation of complex natural flavours by biotransformation of apple pomace with basidiomycetes. Food Chem 141:2952–2959

Shalini R, Gupta DK (2010) Utilization of pomace from apple processing industries: a review. J Food Sci Technol 47:365–371

Sun J, Hu X, Zhao G, Wu J, Wang Z, Chen F, Liao X (2007) Characteristics of thin-layer infrared drying of apple pomace with and without hot air pre-drying. Food Sci Technol Int 13:91–97

Zielinska M, Markowski M (2010) Air drying characteristics and moisture diffusivity of carrots. Chem Eng Process 49:212–218

Chen H, Zhang M, Fang Z, Wang Y (2013) Effects of different drying methods on the quality of squid cubes. Dry Technol 31:1911–1918

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007) Effects of pretreatments and drying air temperature on drying behavior of peach slice. Int J Food Sci Technol 42:65–69

Adedeji AA, Gachovska TK, Ngadi MO, Raghavan GSV (2008) Effect of pretreatments on drying characteristics of okra. Dry Technol 26:1251–1256

Celma AR, Francisco C, Fernando LR, Aida R (2013) Thin layer drying behaviour of industrial tomato bye-products in a convective dryer at low temperatures. Res J Biotechnol 8(2):50–60

McMinn WAM (2006) Thin-layer modelling of the convective, microwave, microwave-convective and microwave-vacuum drying of lactose powder. J Food Eng 72:113–123

Celma AR, López-Rodríguez F, Cuadros Blázquez F (2009) Experimental modelling of infrared drying of industrial grape by-product. Food Bioprod Process 87:247–253

Al-Muhtaseb AH, Al-Harahsheh M, Hararah M, Magee TRA (2010) Drying characteristics and quality change of unutilized-protein rich-tomato pomace with and without osmotic pre-treatment. Ind Crop Prod 31:171–177

Kumar N, Sarkar BC, Sharma HK (2012) Mathematical modelling of thin layer hot air drying of carrot pomace. J Food Sci Technol 49:33–41

Meziane S (2011) Drying kinetics of olive pomace in a fluidized bed dryer. Energ Conv Manag 52:1644–1649

Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K (2010) Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour Technol 101:7265–7270

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modelling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46

Doymaz I (2004) Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst Eng 89:281–287

Karaaslan S, Erdem T, Oztekin S (2013) Mathematical modelling and color characteristics of purslane (Portulace oleraceae L.) leaves using different drying methods. Philip Agric Sci 96:267–274

Crank J (1975) The mathematics of diffusion, 2nd edn. Clarendon Press, Oxford

Chayjan RA, Kaveh M (2014) Physical parameters and kinetic modeling of fix and fluid bed drying of terebinth seeds. J Food Process Preserva 38:1307–1320

da Costa SantosD, de Melo QueirozJ, de Figueiredo RMF, de Oliveira ENA (2013) Mathematical modeling for the annatto (Bixa orellana L.) seed drying process. Chil J Agric Res 73:320–326

Mazutti MA, Zabot G, Boni G, Skovronski A, de Oliveira D, Di Luccio M, Oliveira JV, Rodrigues MI, Treichal H, Maugeri F (2010) Mathematical modeling of thin-layer drying of fermented and non-fermented sugarcane bagasse. Biomass Bioenerg 34:780–786

Xiao HW, Pang CL, Wang LH, Bai JW, Yang WX, Gao ZJ (2010) Drying kinetics and quality of Monukka seedless grapes dried in an air-impingement jet dryer. Biosyst Eng 105:233–240

Roberts JS, Kidd DR, Padilla-Zakour O (2008) Drying kinetics of grape seeds. J Food Eng 89:460–465

Sharma SR, Arora S, Chand T (2011) Air drying kinetics of pomegranate seeds. Int J Food Eng 7(2):Article 7

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuffs. Dry Technol 14:2225–2253

Ghodake HM, Goswami TK, Chakraverty A (2006) Mathematical modeling of withering characteristics of tea leaves. Dry Technol 24:159–164

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Sobukola OP, Dairo OU, Odunewu VA (2008) Convective hot air drying of blanched yam slices. Int J Food Sci Technol 43:1233–1238

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE, St. Joseph

Corzo O, Bracho N, Pereira A, Vásquez A (2008) Weibull distribution for modelling air drying of coroba slices. LWT-Food Sci Technol 41:2023–2028

Celma AR, Rojas S, López F, Montero I, Miranda T (2007) Thin-layer drying behaviour of sludge of olive oil extraction. J Food Eng 80:1261–1271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kara, C., Doymaz, İ. Effective moisture diffusivity determination and mathematical modelling of drying curves of apple pomace. Heat Mass Transfer 51, 983–989 (2015). https://doi.org/10.1007/s00231-014-1470-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1470-6