Abstract

In spite of the classic approaches of solution of dynamic facility layout problem, which only material handling and rearrangement costs are considered as objective function, these problems are the multi-objective problems. In this paper, a mixed integer linear programming formulation is presented for multi-objective dynamic facility layout problem concerning flexible bay structure. In addition, three current objectives in dynamic facility layout problems including minimizing material handling and rearrangement costs, maximizing adjacency rate, and minimizing shape ratio difference have been considered. Also, for solving this problem, two methods including the GAMS software and proposed parallel variable neighborhood search (PVNS) algorithm are used. So, it is worth mentioning that four test problems are solved by them, and the results show that the proposed PVNS algorithm is more efficient than the GAMS software.

Similar content being viewed by others

References

Balakrishnan J, Cheng CH (1998) Dynamic layout algorithms: a state of the art survey. Omega 26(4):507–521

Montreuil B, Venkatadri U (1991) Strategic interpolative design of dynamic manufacturing systems layouts. Manag Sci 37(6):682–694

Montreuil B, Laforge A (1992) Dynamic layout design given a scenario tree of probable futures. Eur J Oper Res 63(2):271–286

Lacksonen TA (1994) Static and dynamic layout problems with varying areas. J Oper Res Soc 45(1):59–69

Dunker T, Radons G, Westkamper E (2005) Combining evolutionary computation and dynamic programming for solving a dynamic facility layout problem. Eur J Oper Res 165(1):55–69

DongM WuC, Hou F (2009) Shortest path based simulated annealing algorithm for dynamic facility layout problem under dynamic business environment. Expert Syst Appl 36:11221–11232

McKendallJr AR, Hakobyan A (2010) Heuristics for the dynamic facility layout problem with unequal-area departments. Eur J Oper Res 201:171–182

Singh SP, Sharma RRK (2006) A review of different approaches to the facility layout problems. Int J Adv Manuf Technol 30:425–433

Armour GC, Buffa ES (1963) A heuristic algorithm and simulation approach to relative allocation of facilities. Manag Sci 9:294–309

Buffa ES, Armour GC, Vollmann TE (1964) Allocating facilities with CRAFT. Harv Bus Rev 42:136–158

Muther R (1974) Systematic layout planning (SLP), 2nd edn. Cahners Books, Boston

Malakooti B (1989) Multiple objective facility layout: a heuristic to generate efficient alternatives. Int J Prod Res 27(7):1225–1238

Rosenblatt MJ (1979) The facility layout problem: a multi-goal approach. Int J Prod Res 17(4):323–332

Harmonosky CM, Tothero GK (1992) A multi-factor plant layout methodology. Int J Prod Res 30(8):1773–1789

Lin LC, Sharp GP (1999) Application of the integrated framework for the plant layout evaluation problem. Eur J Oper Res 116:118–138

Deb KS, Bhattacharyya B (2005) Fuzzy decision support system for manufacturing layout planning. Decision Support Syst 40:305–314

Aiello G, Enea M, Galante G (2006) A multi-objective approach to facility layout problem by genetic search algorithm and Electre method. Robot Comput Integr Manuf 22:447–455

Christu Paul R, AsokanP PVI (2006) A solution to the facility layout problem having passages and inner structure walls using particle swarm optimization. Int J Adv Manuf Technol 29:766–771

Şahin R, Türkbey O (2009) A simulated annealing algorithm to find approximate Pareto optimal solutions for the multi-objective facility layout problem. Int J Adv Manuf Technol 41:1003–1018

Ramkumar AS, Ponnambalam SG, Jawahar N (2009) A population-based hybrid ant system for quadratic assignment formulations in facility layout design. Int J Adv Manuf Technol 44:548–558

Konak A, Kulturel-Konak S, Norman BA, Smith AE (2006) A new mixed integer programming formulation for facility layout design using flexible bays. Oper Res Lett 34:660–672

Ardestani Jaafari A, Krishnan K, Hashemi Doulabi SH, Davoudpour H (2009) A multi-objective formulation for facility layout problem. In: Proceedings of the World Congress on Engineering and Computer Science, San Francisco, USA, vol II

Tong X (1991) SECOT: a sequential construction technique for facility design. Ph.D. thesis, University of Pittsburgh

Tate DM, Smith AE (1995) Unequal-area facility layout by genetic search. IIE Trans 27(2):465–472

Arapoglu RA, Norman BA, Smith AE (2001) Locating input and output points in facilities design—a comparison of constructive, evolutionary, and exact methods. IEEE Trans Evol Comput 5(2):192–203

Kulturel-Konak S, Norman BA, Coit DW, Smith AE (2004) Exploiting tabu search memory in constrained problems. INFORMS J Comput 16(2):241–254

Kulturel-Konak S, Smith AE, Norman BA (2007) Bi-objective facility expansion and relayout considering monuments. IIE Trans 39(2):747–761

Kulturel-Konak S, Konak A (2010) Unequal area flexible bay facility layout using ant colony optimization. Int J Prod Res 49:1877–1902

Enea M, Galante G, Panascia E (2005) The facility layout problem approached using a fuzzy model and a genetic search. J Intell Manuf 16(2):303–316

Alagoz O, Norman BA, Smith AE (2008) Determining aisle structures for facility designs. IIE Trans 40(2):1019–1031

Yang CL, Chuang SP, Hsu TS (2011) A genetic algorithm for dynamic facility planning in job shop manufacturing. Int J Adv Manuf Technol 52:303–309

Wong KY, Komarudin (2010) Solving facility layout problems using flexible bay structure representation and ant system algorithm. Expert Syst Appl 37:5523–5527

Meller RD, Narayanan V, Vance PH (1998) Optimal facility layout design. Oper Res Lett 23:117–127

Sherali HD, Fraticelli BMP, Meller RD (2003) Enhanced model formulations for optimal facility layout. Oper Res 51:629–644

Kuafman A, Gupta MM (1991) Introduction to fuzzy arithmetic: theory and applications. Van Nostrand Reinhold, New York

Bellman RE, Zadeh LA (1970) Decision making in a fuzzy environment. Manag Sci 17:B141–B164

Hwang CL, Lai YJ, KKo MD (1993) ISGP-II for multiobjective optimization with imprecise objective coefficients. Comput Oper Res 20(5):503–514

Letamonphong J, Fang SC, Young RE (2002) Multi objective optimization problems with fuzzy relation equation constraints. Fuzzy Set Syst 127:141–164

Sakawa M, Kato K (2003) An interactive fuzzy satisfying method for multi objective nonlinear integer programming problems through genetic algorithms. Lect Notes Comput Sci 2715:710–717

Zimmermann HJ (1978) Fuzzy programming and linear programming with several objective functions. Fuzzy Set Syst 1:45–55

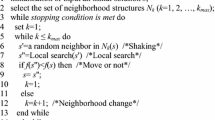

Mladenovic N (1995) A variable neighborhood algorithm—a new metaheuristic for combinatorial optimization. Abstracts of papers presented at Optimization Days, Montréal, pp 112–112

Hansen P, Mladenovic N, Urosevic D (2006) Variable neighborhood search and local branching. Comput Oper Res 33(10):3034–3045

Ye M, Zhou G (2007) A local genetic approach to multi objective, facility layout problems with fixed aisles. Int J Prod Res 45:5243–5264

Mecklenburgh JC (1985) Process plant layout. Longman, New York

Francis RL, McGinnis LF, White JA (1992) Facility layout and location: an analytical approach. Prentice Hall, Englewood Cliffs

Askin RG, Standridge CR (1993) Modelling and analysis of manufacturing systems. Wiley, New York

Fu MC, Kaku BK (1997) Minimizing work-in-process and material handling in the facilities layout problem. IIE Trans 29:29–36

Montreuil B (1990) A modeling framework for integrating layout design and flow network design. In: Proceedings of the material handling research colloquium, Hebron, KY, pp 43–58

Heragu S, Kusiak A (1991) Efficient models for the facility layout problems. Eur J Oper Res 5:1–13

Kim JY, Kim YD (1999) A branch-and-bound algorithm for locating input and output points of departments on the block layout. J Oper Res Soc 50:517–525

Barbosa-Povoa AP, Mateus R, Novais AQ (2001) Optimal two dimensional layout of industrial facilities. Int J Prod Res 39(12):2567–2593

Meller RD, Gau KY (1996) The facility layout problem: recent and emerging trends and perspectives. J Manuf Syst 15:351–366

Tsuchiya K, Bharitkar S, Takefuji Y (1996) A neural network approach to facility layout problems. Int J Prod Res 89:556–563

Malakooti B, Tsurushima A (1989) An expert system using priorities for solving multiple-criteria facility layout problems. Int J Prod Res 27(5):793–808

Kumar SRT, Kashyap RL, Moodie CL (1988) Application of expert systems and pattern recognition methodologies to facilities layout planning. Int J Prod Res 26(5):905–930

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Data set and optimum layout plan obtained for FBS-DFLP-1

-

Width of the plant floor along the x-axis is 11, and length of the plant floor along the y-axis is 6.

-

Number of periods is 3 (i.e., T = 3).

-

Number of departments is 4 (i.e., N = 4).

-

Expected ratio is 4 for all departments in all periods.

-

Maximum number of the parallel bays is 3 in all period.

-

Rearrangement fixed cost is 8 for all departments in all periods.

-

Rearrangement variable cost is 1 for all departments in all periods.

Appendix 2: Data set and optimum layout plan obtained for FBS-DFLP-2

-

Width of the plant floor along the x-axis is 15, and length of the plant floor along the y-axis is 8.

-

Number of periods is 2 (i.e., T = 2).

-

Number of departments is 5 (i.e., N = 5).

-

Expected ratio is 4 for all departments in all periods.

-

Maximum number of the parallel bays is 3 in all period.

-

Rearrangement fixed cost is 12 for all departments in all periods.

-

Rearrangement variable cost is 1 for all departments in all periods.

Rights and permissions

About this article

Cite this article

Abedzadeh, M., Mazinani, M., Moradinasab, N. et al. Parallel variable neighborhood search for solving fuzzy multi-objective dynamic facility layout problem. Int J Adv Manuf Technol 65, 197–211 (2013). https://doi.org/10.1007/s00170-012-4160-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4160-x