Abstract

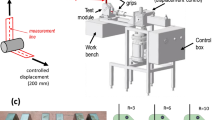

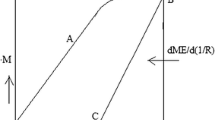

The Bending Under Tension (BUT) machine is used for evaluation of spring back in sheet metal forming. A strip is drawn over a rotating cylindrical die with different restraining forces. The strip is allowed to spring back after drawing and the curvature of the strip is measured. The loading sequence is typical to wall sections of pressed components, side wall curl, where the material has been bent, unbent and finally unloaded. The test was performed on four high and ultra high strength steels with tensile strengths in the range from 800 MPa to 1300 MPa. A clear separation of the data for the four steels was demonstrated. It was analysed to what extent the differences in spring back between the different steels was related to the differences in tensile strengths. A finite element simulation model was used to simulate the strip curvature after BUT testing. The material parameters of the model were fitted to monotonic uniaxial and equibiaxial tests and uniaxial cyclic tests. The model could describe the experimental data in a satisfactory way.

Similar content being viewed by others

References

Pereira MP, Duncan JL, Yan W, Rolfe BF (2009) Contact pressure evolution at the die radius in sheet metal stamping. J Mater Process Technol 209:3532–3541

Chen P, Koc M, Wenner ML (2008) Experimental investigation of spring back variation in forming of high strength steels. J Manuf Sci Eng 130:041006-1-9

Lee MG, Kim SJ, Wagoner RH, Chung K, Kim HY (2009) Constitutive modelling for anisotropic/asymmetric hardening behaviour of magnesium alloy sheets; Application to sheet springback. Int J plasticity 25:70–104

Hilditch TB, Speer JG, Matlock DK (2007) Influence of low-strain deformation characteristics of high strength sheet steel on curl and spring back in bend-under-tension tests. J Mater Process Technol 182:84–94

Chen P, Koc M (2007) Simulation of spring back variation in forming of advanced high strength steels. J Mater Process Technol 190:189–198

Kim HS, Koç M (2008) Numerical investigations on spring back characteristics of aluminum sheet metal alloys in warm forming conditions. J Mater Process Technol 204(1–3):370–383

Wihlborg A, Gunnarsson L (2000) A frictional study of uncoated EBT steel sheets in bending under tension friction test. Wear 237:129–136

Carden WD, Geng LM, Matlock DK, Wagoner RH (2002) Measurement of spring back. Int J Mech Sci 44:79–101

Li KP, Carden WP, Wagoner RH (2002) Simualtion of spring back. Int J Mech Sci 44:103–122

Wagoner RH, Lim H, Lee M-G (2013) Advanced issues in spring back. Int J Plast 45:3–20

Cobo R, Pla M, Hernández R, Benito JA (2009) “Analysis of the decrease of the apparent young’s modulus of advanced high strength steels and its effect in bending simulations”. Proceedings of the iddrg’09, pp.109-117

Cobo R, Hernandez R, Benito JA, Riera MD (2011) “Young’s modulus variation during unloading for a wide range of AHSS steel sheets”: Proceedings of the IDDRG 2011, Bilbao

Melander A, Stenberg N (2013) On the variation of elastic modulus in loading, unloading and reloading, Proceedings of IDDRG 2013, Zurich

Park T, Seok D-Y, Lee C-H, Noma N, Kuwabara T, Stoughton TB, Chung K (2011) Two surface plasticity model and its application to spring back simulation of automotive advanced high strength steel sheets, Proc 8th Int Conf on Numerical simulation of 3D sheet metal forming processes. AIP Conf Proc 1383:1175–1183

Lee J, Lee J-Y, Barlat F, Wagoner RH, Chung K, Lee M-G (2013) Extension of quasi-plastic–elastic approach to incorporate complex plastic flow behaviour—application to spring back of advanced high-strength steel. Int J Plas 45:140–159

Chaboche JL (1991) On some modifications of kinematic hardening to improve the descriptions of racheting effects. Int J Plas 7:661–678

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Chooi SH, Chu E (2003) Plane stress yield function for aluminium alloy sheets – part I:theory. Int J Plas 19:1297–1319

Lee J-W, Lee M-G, Barlat F (2012) Finite element modelling using homogeneous anisotropic hardening and application to spring back prediction. Int J Plas 29:13–41

Li S, Wagoner RH (2011) Complex unloading behavior: nature of the deformation and its consistent constitutive representation. Int J Plas 27:1126–1144

Blumbach, M, Bleck, W, Noll, R, Vrenegor, J, (2005) Online-Fließkurvenermittlung im hydraulischen Tiefungsversuch mit Hilfe des Laserlichtschnittverfarhens, 20th Aachener Stahlkolloquium

Lee J-Y, Xu L, Barlat F, Wagoner RH, Lee M-G (2013) Balanced biaxial testing of advanced high strength steels in warm condition, experimental mechanics. doi:10.1007/s11340-013-9758-x

Lemaitre J, Chaboche J.-L (1990) Mechanics of solid materials. Cambridge University Press

Dassault Systèmes (2010) ABAQUS user manual v 6.10

Wang JF, Wagoner RH, Matlock DK, Barlat F (2005) Anticlastic curvature in draw bend springback. Int J Solids Struct 42:1287–1307

Acknowledgements

The present research was financed by the EU RFCS research programme under the contract SPRINCOM, RFSR-CT-2008-00029, which is gratefully acknowledged. Financial support from The Strategic Research Area in Production Engineering XPRES at KTH is gratefully acknowledged. The authors wish to acknowledge valuable discussions with their partners in the project Centro Sviluppo Materiali, SSAB, Salzgitter Mannesmann, CRF and AMET.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Melander, A., Thoors, H., Stenberg, N. et al. Spring back evaluation for high and ultra high strength sheet steels with the bending under tension machine. Int J Mater Form 8, 137–144 (2015). https://doi.org/10.1007/s12289-013-1155-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1155-6