Abstract

Purpose

The aim of this study was to investigate the factors that influence the sustainability of disposable baby diapers (nappies) using life cycle assessments (LCAs). Size 4 Pampers® Cruisers (North American name) and ActiveFit (European name) from 2007 are compared to new versions made in 2010 to determine if the design and materials changes intended to improve performance also lead to reductions in the most relevant environmental indicators.

Materials and methods

Cradle-to-grave LCAs, consistent with ISO 14040/14044 Standards, are conducted. The functional unit is “the number of diapers needed to collect excreta over a child’s diapering lifetime.” Input data come from P&G, suppliers, trade association reports, Franklin and ecoinvent databases, and Google. SimaPro 7 is used to model the LCA. Several life cycle impact assessments (LCIA) methods, sensitivity analyses, normalization to annual consumption, and Monte Carlo analysis are used to produce and check results.

Results and discussion

The consumption normalization identified that the diaper’s “environmental footprint” should include the IMPACT2002+ indicators: nonrenewable energy, global warming potential (GWP), respiratory effects from inorganics, total solid waste, and cumulative energy demand (CED). Other indicators are insignificant. Contribution analysis shows that the sourcing and production of diaper materials contribute most to the environmental indicators evaluated, accounting for ∼84% of all non-renewable energy uses and ∼64% of global warming potential. Diaper disposal is a small contributor (1–12%) to potential environmental impacts. Reductions observed for the 2010 US product are: CED—8%, solid waste—12%, non-renewable energy—1%, GWP500—4%, and respiratory inorganics—6%. For the European product, reductions are: CED—11%, solid waste—8%, non-renewable energy—3%, GWP500—5%, and respiratory inorganics—14%.

Conclusions

The new Pampers® diapers sold in the USA and Europe have a reduced environmental footprint versus the previous versions (2007). Significant reductions are achieved in non-renewable energy use and global warming potential, as well as other environmental indicators by optimizing the diaper design and the materials. Although some of the results are single digit reductions, Monte Carlo analysis indicates that there is a high probability that the differences are real. The use of multiple LCIA methods to compare products is helpful to confirm consistency of results. Normalizing the LCIA scores to annual consumption also helps prioritize which environmental indicators can be impactful and affected by changing a product.

Similar content being viewed by others

1 Introduction

To achieve sustainable living, communities must balance the environmental, societal, and financial impacts associated with what we produce, use, and discard. Life cycle assessment (LCA) is the only holistic framework that exists today to help us understand the many ways in which a product or service could impact the environment, because LCA forces a rational examination of many indicators throughout material and product manufacture, use, and end-of-life (EOL).

Procter & Gamble (P&G) is the world’s largest consumer products company, selling about 300 brands of products in >130 countries, touching billions of consumers' lives. Pampers is one of its top-selling products globally.

For decades, P&G has worked collaboratively with government, academic, and other industry scientists to develop the methods and assessments to understand and improve both the environmental safety, and life cycles of products that people use every day (Bradbury et al. 2004; Cowan et al. 1995; Cowan-Ellsberry et al. 2004; de Koning et al. 2010; Fava et al. 1991; Pittinger et al. 1991; Saouter et al. 2002; van de Plassche et al. 1999; Versteeg et al. 1999). Multiple life cycle studies of different diapering systems have been conducted for USA and European conditions between 1974 and 2008, several of which were published in open literature (EDANA Sustainability Reports 2005 and 2007; Fava et al. 1990; Franklin and Ltd 1992; Lentz et al. 1989; MRI Project No. 3746-D 1974; Nylander 1991; Sandgren 1993; Sauer et al. 1994; UK Environment Agency 2005, 2008; Vizcarra et al. 1994). Consecutive LCA studies were conducted because several material and design innovations led to significant compositional changes and weight reductions of disposable diapers and their packaging (Fig. S1). Recent LCAs indicate that several material and design innovations in current diapers result in substantially reduced environmental impacts compared to the disposable products of the 1980s, with better performance and improved skin health (EDANA Sustainability Report 2007; UK. Environment Agency 2008). Despite such improvements, P&G surveys and on-line blogs show that some parents feel confused or guilty about how diapers fit with sustainable living approaches, as they try to balance diaper cost, convenience, hygienic containment, baby’s skin health, and uninterrupted sleep, with potential environmental impacts.

In 2005 and 2008, the UK Environment Agency published results of LCA studies of three diaper types: disposable, home-laundered cloth, and commercially laundered cloth diapers delivered to the home (UK Environment Agency 2005; UK Environment Agency 2008). The studies evaluated the potential environmental impacts associated with an average child wearing diapers during the first 2.5 years of life in the UK. The studies found that the environmental impacts of the diapering systems are different; however, none of the three diapering systems were environmentally preferable. The potential environmental impacts are linked to the energy, water, and detergents needed to clean cloth diapers and to raw material production for disposable diapers. The UK studies indicated that the potential environmental impacts of disposable diapers could be reduced by decreasing material use (i.e., product weight or use frequency) and improvements in materials manufacturing, while the impact of reusable cloth diapers could be minimized by reducing the energy required for washing and drying.

Pampers product developers have consistently worked to optimize material use and design, reducing potential environmental impacts called out in the various LCA studies. For example, in the USA, between 1992 and 2010, Pampers® reduced its average diaper product weight by 45% and average packaging weights by 73%. Between 1988 and 2010 in Europe, the average Pampers® diaper weight was reduced by 57% and average packaging weight by 54%. Through a new product design, the 2010 diapers sold in both continents deliver approximately 10% reduction in product weights and 14% reduction in bag package compared to the previous 2007 formulations.

The primary purpose of developing the current Pampers® LCA was to establish a thorough and reliable in-house model to use for future product and material development, and guide improvements for supply chain sustainability. Questions driving this LCA study are: Does the 10% reduction in raw material use for the 2010 Pampers® with DryMax diapers result in a significantly improved “environmental footprint,” with no negative tradeoffs? Which methods are useful to increase the certainty that results are accurate and meaningful for environmental conservation? Which environmental indicators are actually relevant for disposable diapers? What is scientifically accurate to communicate to disposable diaper users about living more sustainably? This report summarizes the methods and key findings of the LCA study comparing the previous 2007 Pampers® Cruisers and ActiveFit diapers to the new versions with DryMax sold in the USA and Europe in 2010.

2 Materials and methods

The LCAs were conducted in 2008–2009 by P&G. External experts verified that the data included are appropriate, the methods are consistent with ISO 14040/14044 Standards, and the conclusions are supportable based on the results (see Electronic supplementary material for method details).

The goal of the cradle-to-grave LCA studies is to compare the attributes of size 4 Pampers® Cruisers (North American name) and ActiveFit (European name) formulas from 2007 to new versions made in 2010. The life cycle phases included are: Raw Materials, Diaper Manufacture (at representative plants in Cape Girardeau, MO, USA and Euskirchen Germany); Packaging; Distribution; and End-of-Life (EOL). Use of the diapers is excluded.

The functional units for this study are “the number of diapers needed to collect excreta over a child’s diapering lifetime”. In the USA, the functional unit is 4,623 diapers, based on a 2007 Pampers® habits and practices survey of diaper users in the USA and Canada. For Europe, the functional unit is 3,796 diapers, consistent with European industry and government LCAs on diapers (EDANA Sustainability Report 2007; UK Environment Agency 2008).

Primary data on formulations, material compositions, primary suppliers and their locations, and production for the diapers are used to the maximum extent possible. Data are compiled from: P&G, several suppliers, a 1995 EDANA LCA Project report for member companies, the Franklin and ecoinvent commercial inventory databases, and Google maps (http://www.maps.google.com).

Used diaper disposal into municipal solid waste sanitary landfills and incinerators are considered. For the USA, 20% of the waste is assumed to be disposed into incinerators and 80% into sanitary landfills (United States Environmental Protection Agency 2009). For Europe, 32% of the waste is assumed to be disposed into incinerators and 68% into sanitary landfills (The Statistical Office of the European Communities 2009).

The commercial LCA software SimaPro 7 is used to model the LCA (Pré Consultants www.pre.nl). The life cycle impact assessment (LCIA) of CML 2000, Eco-indicator99 and TRACI are used to check consistency of IMPACT 2002+ results and verify the conclusions (Bare et al. 2006, 2003; Goedkoop and Spriensma 2001; Jolliet et al. 2003).

Sensitivity analyses are conducted to check completeness and consistency. These analyses evaluated assumptions regarding the accuracy of different pulp and AGM data, significance of the variations in distribution distances, impacts related to solid waste handling, results for cumulative energy demand (CED) and solid waste, and the most relevant indicators from the LCIA.

To evaluate the relevance of the potential environmental impacts from diapers, the contribution of each potential impact is normalized to annual consumption by an average European (reference year 1995) using Simapro. There is no equivalent method to represent US consumption habits.

Parameters indicating the diaper’s environmental footprint include the most relevant IMPACT2002+ indicators identified through the normalization, total solid waste flows, and total energy flows.

As a ‘rule of thumb,’ it is assumed for many LCAs that a 10% difference between the test case and the baseline case qualifies as significant. To provide a more robust assessment for these LCAs, however, the uncertainty of results associated with variability in input data was assessed with 1,000 Monte Carlo iterations.

3 Results

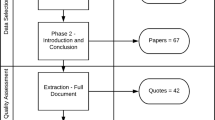

For the new 2010 formulations, there is no significant increase (+10%) for any environmental indicator. Additionally, for almost all indicators, the 2010 case has lower scores than the 2007 baseline case. Figure 1 shows the “rule of thumb” comparison for all IMPACT2002+ midpoint categories for the 2010 vs. 2007 in Western Europe. Results for the US case are very similar (see Fig. S2). Results are similar for the other LCIA methods, including EcoIndicator 99, CML 2000, and TRACI (see Figs. S3, S4). Note that the land occupation indicator is significantly lower for the 2010 case since the pulp content was reduced.

Normalization indicates that non-renewable energy, global warming, and respiratory effects from inorganics are the most relevant of the potential environmental impacts for the diapers. Figure 2 shows the IMPACT2002+ midpoint category results per US functional unit normalized to average consumption habits for Europe. (At the time of this study, average US consumption data were not available, so European values were assumed to be similar and used for both regions.) A result of 0.08 for nonrenewable energy means that the chosen amount of diapers could contribute about 8% of all non-renewable energies consumed by an American citizen during 1 year. In contrast, the diapers contribute <0.5% to the land used to support an American citizen’s annual consumption. Results for the Western European case are very similar (see Fig. S5).

Normalized Impact2002+ midpoint categories for the 2010 (green) vs. 2007 (red) diapers in the USA. Asterisks indicate that the potential impact is associated with power generation, not directly related to product manufacture or use. The diapers have potentially relevant contributions to three of 15 environmental impact indicators estimated by this LCIA method

The three most relevant indicators are highly correlated to energy use throughout the life cycle. Non-renewable energy measures the amount of energy extracted from the earth contained in the fossil energy carrier (coal, oil, and natural gas) or uranium ore. Electricity, heat and fuel production and consumption are the main consumer of fossil fuels and uranium ore. Global warming covers a range of potential impacts resulting from a change in the global climate. It is the measured heat-trapping effect of a greenhouse gas (GHG) released in the atmosphere. CO2 emitted by fossil fuel combustion is the main GHG. Respiratory effects from inorganics are air pollutants such as fine particles that affect human lungs. These pollutants are released by heavy industries and road traffic.

Monte Carlo simulations for the Western Europe case are shown in Fig. 3. Results for the US case are similar (see Fig. S6). In some instances, the difference between the 2007 and 2010 cases are small; however, taking into account uncertainty, there is a high probability that the difference is real. Results indicate that the new 2010 diaper is better in 60–100% of the iterations for the three most relevant indicators (non-renewable energy, global warming, and respiratory effects from inorganics), so the indicator scores appear to be largely certain. Both for the US and Western Europe cases, the 95% confidence interval for the difference between the 2007 and 2010 case is always positive for respiratory inorganic effects; there is a 2.5% chance of a type I error. For global warming and non-renewable energy, the probabilities of a better score for the 2010 case are 95% and 86%, respectively.

Monte Carlo analysis comparing 2007 (green) with 2010 (red) diapers in the Western Europe shows the percentage of the iterations when the difference between the two formulations is negative (i.e., the 2007 diaper is better) and positive (i.e., the 2010 diaper is better). The bold boxes indicate the most relevant midpoint categories identified in Fig. 2. Asterisks indicate that the potential impact is associated with power generation, not directly related to product manufacture or use

Sourcing and production of raw materials is the key contributing life cycle stage to the environmental impact indicators for both diaper formulations. Figure 4 shows the relative contributions of the different life cycle stages to the most relevant IMPACT2002+ midpoint categories. Raw materials (blue section) represent 63–92% of the total. Of the raw materials, polypropylene and the absorbent gelling material (AGM) are the primary contributors to the three most relevant impact indicators (chart not shown).

Although contributing significantly less impact than raw material production, the other life cycle phases (manufacturing, packaging, distribution, and end-of-life) present opportunities for improvement. P&G manufacturing is the second most important driver for respiratory effects from inorganics and non-renewable energy. This is related to the electricity use in the plant for which both WE and the USA highly rely on fossil fuels. Packaging contributions are mostly associated with its raw material production, but since overall packaging weight per diaper is a small fraction relative to diaper weight, its proportional contribution is lower. Impacts from transport (both from raw materials to the P&G plant and transport associated with distribution to retailers) are also small. This is largely because energy requirements for raw material production are far larger than for truck and ship fuel. Finally, in contrast to public perceptions, the disposal (end-of-life) of the used diapers (orange section) contributes just 1–12% to the relevant environmental impact indicators. The greater contribution of disposal is to global warming potential (GWP or “carbon footprint”) in relation to the biodegradation of the pulp in the diapers and to (non-recycled) packaging in a sanitary landfill.

Although solid waste is not a significant contributor to environmental impacts, used diaper waste causes caregivers concern because they see much of it; consumer use of the product contributes about 60% (59–60% NA, 67–70% WE) to the total waste generated throughout the life cycle of Pampers diapers. Figure 5 shows that the 2010 formulations leads to less solid waste generated (−12% in NA and −8% in WE) than the previous 2007 versions.

For the US functional unit (4,623 diapers), the used diapers themselves are estimated to contribute 153 kg from the 2007 diapers compared to 133 kg from the 2010 diapers. Diaper raw material production generates the next largest amount of waste for the 2007 and 2010 diapers (23% for both), then packaging (10% for both), P&G manufacturing (7% and 8%, respectively), and distribution (<1%).

For the European functional unit (3,796 diapers), the largest waste flow is the used diapers, estimated at 138 kg for the previous 2007 product and 115 kg for the 2010 diapers. Diaper component production generates the next largest amount of waste for the 2007 and 2010 diapers (21% and 20%, respectively), then packaging (4% and 6%), P&G manufacturing (4% and 5%), and distribution (1% for both). Solid waste associated with raw material production is primarily driven by waste from energy usage by suppliers, such as mining waste and treatment of combustion ashes from coal combustion processes in electricity production.

On average, baby diapers comprise about 1.6% in the USA and up to 3% in European Union of municipal solid waste (MSW) streams (Colon et al. 2011; EDANA Sustainability Report 2007; United States Environmental Protection Agency 2009). The statistics for diaper disposal within each state or country is not available in published government data. For comparison to another waste stream, food scraps, and yard wastes contribute about 25% and 27% in USA and Western Europe MSW streams, respectively (Eurostat 2003; United States Environmental Protection Agency 2009).

The method to calculate CED was developed in Germany and further developed for the ecoinvent database (Ecoinvent Report No. 3 2007). Energy production processes are classified into: non-renewable fossil energy (e.g., oil, natural gas, coal), non-renewable nuclear energy flows (e.g., uranium), renewable biomass energy flows (e.g., wood), renewable wind, solar and geothermal energy flows, and renewable hydro energy flows. CED is obtained by converting each type of energy into the same unit (megajoule), based on their inherent energy content (i.e., heat content in megajoules per kilogram) for the mass quantified flows.

Figure 6 shows that the reduction in CED for the 2010 diaper is essentially due to the reduction in pulp used and the associated biomass energy used in its production in the supply chain. The new optimized design and new AGM has a neutral effect, in that they do not lead to any change in energy use.

For the US 2010 formulation, there is a reduction by −1,319 MJ CED (−8%) compared to the previous 2007 Cruisers version on a functional unit basis. Sourcing and production of raw materials contribute 83% of the total energy for both the 2007 and 2010 diapers, and is the only life cycle stage that shows a significant change between the two cases, due to the reduced pulp usage.

For the European formulation, CED is reduced by −1,454 MJ (−11%) for the 2010 diaper compared to the previous 2007 ActiveFit diaper. Similar to the US product, this reduction in the European version is due to the pulp reduction, which accounts for the biomass energy flows (−1,063 MJ or 73% of the total reduction). The raw materials production and components manufacturing stage contributes 84% and 81% of the total energy demand for the 2007 and 2010 diapers, respectively. The diapers manufacturing and packaging contribute 9% and 5%, respectively.

4 Discussion

-

Which environmental indicators are actually relevant for disposable diapers? Does the 10% reduction in raw material use for the 2010 Pampers® with DryMax diapers result in a significantly improved “environmental footprint,” with no negative tradeoffs?

The diaper’s “environmental footprint” includes the most relevant IMPACT2002+ indicators identified in Fig. 2 (non-renewable energy, GWP, and respiratory effects from inorganics), total solid waste, and CED. Only reductions were observed in these footprint factors with the 2010 products. Although some of the results are single digit reductions, the Monte Carlo analysis (Fig. 3) indicates that there is a high probability that the differences are real.

Several reductions were calculated in the LCA for the 2010 US product (having the 10% reduced material usage): CED—8%, solid waste—12%, non-renewable energy—1%, GWP500—4%, and respiratory inorganics—6%. Although not reported as part of the environmental footprint factors, the formulation changes also lead to about 23% improvement in transportation efficiency due to improved pallet fit of diaper packs on trucks. Fewer trucks (2,278) per year were estimated to be needed to transport the products (equal to approx. 683,400 gal (2.6 million liters) of diesel fuel).

For Europe, the reductions associated with the 2010 product are: CED—11%, solid waste—8%, non-renewable energy—3%, GWP500—5%, and respiratory inorganics—14%. Unlike in the US case, there is no significant reduction related to distribution.

With regard to climate change and greenhouse gases, the 2007 and 2010 European products are similar within the accurateness achievable with LCAs. Although there is a −3% reduction in GWP500 for the 2010 vs. 2007 diaper, which is statistically significant according to MonteCarlo, the GWP100 (results not shown) is increased by +3%. There is no external expert resolution on which time scale is best to use, and the differences are small (<10%). The GWP500 value is reported in this study simply because that is the timeframe included in the IMPACT2002+ LCIA method.

Both for Europe and the USA, the changes in non-renewable energy between the 2007 and 2010 cases are small. This is because with the reformulation, there was a tradeoff between further light-weighting diapers (decreasing the use of non-woven fabrics mostly sourced from petroleum), on the one hand, and the reduction of pulp with a more absorbent AGM (fossil fuel-derived) on the other hand.

“Respiratory effects from inorganics” are one of the examples in LCA where it is important to not only understand relevance of potential impacts, but the practicality of them. This indicator is the result of a time and space integrated model, whereby such emissions from energy production that could have an effect on human health (in this case, on the respiratory tract) are tallied for an exposure estimate. Although “respiratory effects from inorganics” is a relevant indicator based on normalized consumption, the emissions driving this are regulated and permitted, so the actual release of these substances is not considered a true hazard for how the electricity is produced that is used to make diapers. For decades, all P&G diaper products and operations have been regularly assessed by internal and external experts and found to be safe for humans and the environment. At P&G manufacturing sites, exposures and releases are measured, carefully controlled for permit compliance, and assessed by several engineering and safety science departments.

-

Which methods are useful to increase the certainty that results are accurate and meaningful for environmental conservation?

Three methods were used to assess the accuracy and meaning of the LCA results:

-

1.

The consistency of results was checked against three LCIA methods and the most meaningful endpoints were identified with normalized consumption habits. It is reassuring that three different LCIA methods, varying in underlying exposure model and geographical scope, lead to similar conclusions when both diapers are compared.

-

2.

Uncertainty due to data variability was assessed with Monte Carlo analyses and showed that even though differences between both diapers are small, they are probably real.

-

3.

Finally, uncertainty in the model due to lack of information (assumptions) was assessed by sensitivity analyses, evaluating if alternative assumptions lead to different conclusions. This assessment showed that the scale of the differences may change, but not the direction of the difference. The main conclusions are the same.

A previous study of detergents helped our understanding of the sources of uncertainty and how uncertainty varies with the comparison one wishes to make (de Koning et al. 2010). That analysis showed that the uncertainty margins of GWP broaden as the assessment of several detergents moves from a comparison conducted within a company and its product forms, to a comparison with data from third parties (e.g., competitors). The uncertainty margins are larger when more data assumptions are necessary due to the confidential nature of competitors’ processes, ingredients, etc. The within-company comparisons can clearly distinguish GWP differences between products, whereas due to greater uncertainty, distinguishing among competitive products is not possible with high resolution.

-

What is scientifically accurate to communicate to disposable diaper users about living more sustainably?

Communicate of improvements related to the top three impact indicators—GWP, energy, and respiratory effects from inorganics—because these indicators are actually relevant for disposable diapers based on normalized consumption. Statements about environmental improvements coming from factors that less or irrelevant indicators (e.g., land occupation) could be misleading to consumers and not actually benefit the conservation of resources or environmental protection.

Results shown in Fig. 4 are consistent with the UK Environmental Agency’s studies (UK Environment Agency 2005; UK Environment Agency 2008) finding that environmental impacts are linked to raw material production for (general) disposable diapers. For the sustainable development of disposable diapers, the LCA results lead to the basic guidance to: “Use less raw materials and/or optimize resources used within the supply chains.”

Although it is hard to make a small diaper smaller, Pampers plans to continue find ways to optimize raw material use and balance product performance with a reduced product weight and environmental footprint.

In May 2010, P&G launched an Environmental Sustainable Supplier Scorecard to its top 400+ suppliers; results will be used in 2011/12 to help rank supplier performance, and used to set future buying contracts. This effort appears to be one of the first (and very large) attempts to systematize the inclusion of sustainability with cost, quality, and reliability in business decision making. The scorecard effort is also intended to encourage companies to build their capabilities to track several metrics involved with sustainable operations (e.g., energy use, water use, emissions, waste). Without tracking or building such capabilities, companies do not know what improvements to make to optimize resource use. Ultimately, the expanded tracking capability should benefit the development of material specific life cycle inventories. For products with LCA profiles like disposable diapers, designing more effective products and influencing behaviors in the supply chain are the most impactful things that a corporation can do to achieve sustainable product development and enable more sustainable living.

Almost all human activities, with the many processes and products involved, have some environmental impact. Making comparative assertions about competing diapering systems may be very difficult from a practical and statistical standpoint. Such assertions may also not be helpful for baby caregivers trying to balance diaper cost, convenience, hygienic containment, baby’s skin health and uninterrupted sleep, with potential environmental impacts. Different diapering systems exist because consumers have different needs across those areas, and they will use what works best for their children and lifestyle.

References

Bare J, Gloria T, Norris G (2006) Development of the method and US Normalization Database for life cycle impact assessment and sustainability metrics. Environ Sci Technol 40(16):5108–5115

Bradbury SP, Feijtel TCJ, Van Leeuwen CJ (2004) Meeting the scientific needs of ecological risk assessment in a regulatory context. Environ Sci Technol 38:463–470

Colon J, Ruggieri L, Sánchez A, González A, Puig I (2011) Possibilities of composting disposable diapers with municipal solid wastes. Waste Manag Res 29:249–259

Cowan CE, Versteeg DJ, Larson RJ, Kloepper-Sams PJ (1995) Integrated approach for environmental assessment of new and existing chemicals. Regul Toxicol Pharmacol 21:3–31

Cowan-Ellsberry CE, Belanger SE, Versteeg DJ, Boeije G, Feijtel TCJ (2004) The application of environmental risk assessment to detergent ingredients in consumer products. In: Zoeller U (ed) Handbook of Detergents, Part F, Environmental Impact. Marcel Dekker, New York, pp 347–372

de Koning A, Schowanek D, Dewaele J, Weisbrod AV, Guinée J (2010) Uncertainties in a carbon footprint model for detergents; quantifying the confidence in a comparative result. Int J Life Cycle Assess 15:79–89

Ecoinvent Report No. 3 (2007) Implementation of Life Cycle Impact Assessment methods, Data v2 2007; Ecoinvent Centre, Dübendorf, Switzerland, 2007; http://www.ecoinvent.org/fileadmin/documents/en/03_LCIA-Implementation.pdf

EDANA Sustainability Report (2007) Absorbent hygiene products. Brussels, Belgium

EDANA Sustainability Report (2005) LCA trend analysis on adult incontinence products. Brussels, Belgium

Eurostat (2003) Waste generated and treated in Europe. Report 2003

Fava JA, Curran MA, Boustead I, Parrish R (1990) Energy and environmental profile analysis of children’s disposable and cloth diapers, Peer Review Panel. Comments on Franklin Associates, Ltd. Report. Kansas

Fava JA, Denison B, Jones B, Curran MA, Vigon B, Selke S, Barnum J (1991) A technical framework for life-cycle assessments. SETAC Foundation for Environmental Education, Washington, DC

Franklin Associates, Ltd. (1992) Report. Energy and Environmental Profile Analysis of Children’s Disposable and Cloth Diapers, Revised Report. Kansas

Goedkoop M, Spriensma R (2001) PRé Consultants BV. The Eco-indicator 99. A damage oriented method for Life Cycle Impact Assessment. Methodology Report. 2001; Amersfoort, the Netherlands; http://teclim.ufba.br/jsf/indicadores/holan%20ecoindicator%2099.pdf

Jolliet O, Margni M, Charles R, Humbert S, Payet J, Rebitzer G, Rosenbaum R (2003) Impact 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assessment 8(6):324–330

Lentz R, Franke M, Thomé-Kozmiensky KJ (1989) Vergleichende Umweltbilanzen für Produkte am Beispiel von Höschen- und Baumwollwindeln. In: Thomé-Kozmiensky KJ (ed) Schenkel W. Konzepte in der Abfallwirtschaft; EF Verlag für Energie- und Umwelttechnik GmbH, Germany

MRI Project No. 3746-D (1974) Resource and environmental impacts of pampers disposable diapers and cloth diapers. Final Report to the Procter & Gamble Company, Midwest Research Institute, Kansas City, Missouri

Nylander G (1991) Disposable diapers—cloth diapers: a comparison. STFI, Stockholm, Sweden

Pittinger CA, Rothgeb TM, Hunnicutt ML (1991) Environmental lifecycle analyses of surfactants and surfactant precursors. International News on Fats, Oils and Related Materials 2:343–344

Sandgren J (1993) Screening life cycle assessment for comparison of cloth and disposable diapers used in Norway. Technical Report to the Norwegian State Pollution Control Authority, Det Norske Veritas Industri Norge AS, Project No.92302019. Hovik, Norway

Saouter E, Van Hoof G, Feijtel TCJ, Owens JW (2002) The effect of compact formulations on the environmental profile of Northern European granular laundry detergents—Part II: life cycle assessment. Int J Life Cycle Assess 7:27–38

Sauer BJ, Hildebrandt CC, Franklin WE, Hunt RG (1994) Resource and environmental profile analysis of children’s diaper systems. Environ Toxicol Chem 13(6):1003–1009

The Statistical Office of the European Communities (2009) Half a ton of municipal waste generated per person in the EU27 in 2007. Almost 40% of this waste was recycled or composted. Brussels Belgium, 2009. Stat/09/31

Environment Agency UK (2005) Science Project reference: P1481. Life Cycle Assessment of Disposable and Reusable Nappies in the U.K, Bristol, UK

U.K. Environment Agency (2008) Science Report: SC010018/SR2. An updated lifecycle assessment study for disposable and reusable nappies. Bristol, UK. http://publications.environment-agency.gov.uk/pdf/SCHO0808BOIR-e-e.pdf

United States Environmental Protection Agency (2009) Municipal solid waste generation, recycling, and disposal in the United States: facts and figures for 2008. Washington, DC, 2009. EPA-530-F-009-021

van de Plassche EJ, de Bruijn JHM, Stephenson RR, Marshall SJ, Feijtel TCJ, Belanger SE (1999) Predicted no-effect concentrations and risk characterization of four surfactants: linear alkyl benzene sulfonate, alcohol ethoxylates, alcohol ethoxylated sulfates, and soap. Environ Toxicol Chem 18:2653–2663

Versteeg DJ, Belanger SE, Carr GJ (1999) Understanding single species and model ecosystem sensitivity: data-based comparison. Environ Toxicol Chem 18:1329–1346

Vizcarra AT, Liao PH, Lo KV (1994) A life-cycle inventory of baby diapers subject to Canadian conditions. Environ Toxicol Chem 13(10):1707–1716

Acknowledgments

We thank Jessica Brill for the editorial assistance and Prof. Dr. Walter Kloepffer (editor-in-chief, International Journal of Life Cycle Assessment) and Dr. Mary Ann Curran (LCA research program leader, Sustainable Technology, U.S. EPA) for their expert review of the LCAs in accordance with ISO 14040/14044 Guidelines. Both acted as consultants in this capacity and do not represent their employers.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

Supporting information paragraph: supporting information available on material and methods and additional figures. (DOC 1627 kb)

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Weisbrod, A.V., Van Hoof, G. LCA-measured environmental improvements in Pampers® diapers. Int J Life Cycle Assess 17, 145–153 (2012). https://doi.org/10.1007/s11367-011-0343-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-011-0343-1