Abstract

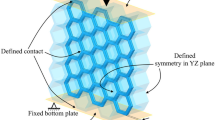

The effect of the helical wood fiber structure on in-plane composite properties has been analyzed. The used analytical concentric cylinder model is valid for an arbitrary number of phases with monoclinic material properties in a global coordinate system. The wood fiber was modeled as a three concentric cylinder assembly with lumen in the middle followed by the S3, S2 and S1 layers. Due to its helical structure the fiber tends to rotate upon loading in axial direction. In most studies on the mechanical behavior of wood fiber composites this extension-twist coupling is overlooked since it is assumed that the fiber will be restricted from rotation within the composite. Therefore, two extreme cases, first modeling fiber then modeling composite were examined: (i) free rotation and (ii) no rotation of the cylinder assembly. It was found that longitudinal fiber modulus depending on the microfibril angle in S2 layer is very sensitive with respect to restrictions for fiber rotation. In-plane Poisson’s ratio was also shown to be greatly influenced. The results were compared to a model representing the fiber by its cell wall and using classical laminate theory to model the fiber. It was found that longitudinal fiber modulus correlates quite well with results obtained with the concentric cylinder model, whereas Poisson’s ratio gave unsatisfactory matching. Finally using typical thermoset resin properties the longitudinal modulus and Poisson’s ratio of an aligned softwood fiber composite with varying fiber content were calculated for various microfibril angles in the S2 layer.

Similar content being viewed by others

References

Mueller, D.H., Krobjilowski, A.: New Discovery in the Properties of Composites Reinforced with Natural Fibers. J. Ind. Text. 33, 111–129 (2003)

Lilholt H., Lawther J.M.: Natural Organic Fibers. In Kelly A., Zweben C. (eds.-in-chief) Comprehensive Composite Materials, ch 1.10. Elsevier Ltd, (2000)

Bledzki, A.K., Faruk, O.: Wood Fibre Reinforced Polypropylene Composites: Effect of Fibre Geometry and Coupling Agent on Physico-Mechanical Properties. Appl. Compos. Mater. 10, 365–379 (2003)

Mahlberg, R., Paajanen, L., Nurmi, A., Kivistö, A., Koskela, K., Rowell, R.M.: Effect of chemical modification of wood on the mechanical and adhesion properties of wood fiber/polypropylene fiber and polypropylene/veneer composites. Holz als Roh- und Werkstoff 59, 319–326 (2001)

Brändström, J.: Micro- and ultrastructural aspects of Norway spruce tracheids: a review. IAWA J. 22, 333–353 (2001)

Stöckmann, V.: Effect of pulping on cellulose structure. Part I. A hypothesis of transformation of fibrils. TAPPI. 54, 2033–2037 (1971)

Stöckmann, V.: Effect of pulping on cellulose structure. Part II. Fibrils contract longitudinally. TAPPI. 54, 2038–2045 (1971)

Nyström, B., Joffe, R., Långström, R.: Microstructure and strength of injection molded natural fiber composites. J. Reinf. Plast. Compos. 26, 579–599 (2007)

Marklund, E., Varna, J., Neagu, R.C., Gamstedt, E.K.: Stiffness of aligned wood fiber composites: Effect of microstructure and phase properties. J. Compos. Mater. 42, 2377–2405 (2008)

Marklund, E., Varna, J.: Modeling the Hygroexpansion of Aligned Wood Fiber Composites. Compos. Sci. Technol. 69, 1108–1114 (2009)

Lekhnitskii, S.G.: Theory of Elasticity of an Anisotropic Body. Mir Publishers, Moscow (1981)

Tarn, J.-Q., Wang, Y.-M.: Laminated composite tubes under extension, torsion, bending, shearing and pressuring: a state space approach. Int. J. Sol. Struct. 38, 9053–9075 (2001)

Tang, R.C.: Three-Dimensional Analysis of Elastic Behavior of Wood Fiber. Wood Fib. Sci. 3, 210–219 (1972)

Davies, G.C., Bruce, D.M.: A stress analysis model for composite coaxial cylinders. J. Mater. Sci. 32, 5425–5437 (1997)

Jolicoeur, C., Cardou, A.: Analytical solution for bending of coaxial orthotropic cylinders. J. Eng. Mech. 120, 2556–2574 (1994)

Neagu, R.C., Gamstedt, E.K.: Modelling of effects of ultrastructural morphology on the hygroelastic properties of wood fibres. J. Mater. Sci. 42, 10254–10274 (2007)

Salmén, L.: Micromechanical understanding of the cell-wall structure. Comptes Rendus Biologies 327, 873–880 (2004)

Cousins, W.J.: Elastic modulus of lignin as related to moisture content. Wood Sci. Technol. 10, 9–17 (1976)

Cousins, W.J.: Young’s modulus of hemicellulose as related to moisture content. Wood Sci. Technol. 12, 161–167 (1978)

Cave, I.D.: Modelling moisture-related mechanical properties of wood Part II: Computation of Properties of a Model of Wood and Comparison with Experimental Data. Wood Sci. Technol. 12, 127–139 (1978)

Page, D.H., El-Hosseiny, F., Winkler, K., Bain, R.: The mechanical properties of single wood pulp fibres Part I: A new approach. Pulp Paper Mag. Can. 73, 72–77 (1972)

Page, D.H., El-Hosseiny, F., Winkler, K., Lancaster, A.P.S.: Elastic modulus of single wood pulp fibres. TAPPI. 60, 114–117 (1977)

Acknowledgements

Financial support from VINNOVA in collaboration with STFI-Packforsk AB via the NFNM III program is gratefully acknowledged. Dr. Cristian Neagu at EPFL and Associate Professor Kristofer Gamstedt at KTH are acknowledged and very much appreciated for their insightful comments during this work.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

Stiffness transformation equations

The cell wall layer in the symmetry axes (L,T,r) is an unidirectional composite described as an orthotropic material with the stiffness matrix

The stiffness matrix of this material in the global (z, φ, r)-system is given by (1). The stress components in the global system can be expressed through stresses in the local (L,T,r)-system using the well known tensor transformation expressions with rotation around the r-axis

\( {\left[ \sigma \right]_{z,\varphi, r}} \) and \( {\left[ \sigma \right]_{L,T,r}} \) is the stress component matrix in the global and local coordinates respectively, \( \left[ \alpha \right] \) is the matrix of orientation cosines with elements defined as \( {\alpha_{ik}} = \cos \left( {x_i^\prime, {x_k}} \right) \) for i,k = 1,2,3, where \( x_i^\prime \)is the coordinate axis in the local system and \( {x_k} \)is the axis in the global system. It can be shown that using notation \( m = \cos \theta \), \( n = \sin \theta \), see Fig. 1, we have the following expression

Using (A3) in (A2) we obtain the following transformation matrix in vector form

Stiffness transformation expressions relating material stiffness matrix in the global (z, φ, r)-system with the stiffness in the local (L,T,r)-system can be obtained using a formal chain of rearrangements

The strain transformation in the last step in (A5) is slightly different because we are transforming engineering and not tensorial strains. Since (A5) establishes a relationship between stresses and strains in the global system, the matrix product linking them is the stiffness matrix of the material in these coordinates

Appendix B

Strain –displacement relationships and stress equilibrium equations

The relationships between strain and displacement components in a cylindrical system of coordinates are

In the following we consider loading cases where stress and strain components are z and φ independent, εz = ε0 and the tangential tractions on the internal boundary r = r 0 and also on the external boundary r = r N of the sub-cylinder assembly are zero. The expressions for displacements and strains become

The fiber in the composite (and even without the composite) is considered as infinitely long which means that there are no end effects and hence physical characteristics like strains and stresses cannot depend on the z-coordinate. Under such condition the stress equilibrium equations are

The applied load in this study is independent on the φ-coordinate. Hence, we can expect that stresses will not have this dependence either since there is no prioritised direction and even if the fiber is rotating, the response can not be φ-dependent. Under this assumption (B4) turns into

The conditions of zero tangential tractions on the internal boundary and on the external boundary of the sub-cylinder assembly give (in any sub-cylinder) \( {\sigma_{zr}} \equiv {\sigma_{\varphi r}} \equiv 0 \).

Appendix C

Solution for problem with r-dependent stress-strain state

Using the constitutive Eq. (1) in the first Eq. (B5) leads to

Substitute expressions from (B3) in (C1)

The general solution of Eq. (C2) is

where

For isotropic or transversely isotropic materials \( {a_1} = {a_2} = 0 \). Now strains may be calculated using (B3)

Expressions for stresses can be obtained using the constitutive Eq. (1)

where

Rights and permissions

About this article

Cite this article

Marklund, E., Varna, J. Modeling the Effect of Helical Fiber Structure on Wood Fiber Composite Elastic Properties. Appl Compos Mater 16, 245–262 (2009). https://doi.org/10.1007/s10443-009-9091-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-009-9091-9