Abstract

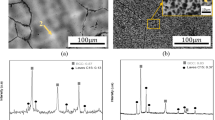

Tungsten is used by some duplex stainless steel producers for partial substitution of molybdenum, both elements enhancing the corrosion resistance of duplex stainless steel. The negative aspect of both molybdenum and tungsten alloying is that they increase the tendency to precipitate intermetallic phases, which may have a detrimental effect on corrosion and mechanical properties. The temperature region for intermetallic phase precipitation is about 700–1000 °C, depending on alloy composition, and the time for precipitation is within minutes for superduplex steels.There has been scientific discussion on the relative effects of Mo alone or Mo-W on intermetallic precipitation behaviour in superduplex steels for the past two decades. While the base material response to ageing and precipitation of intermetallic phases has been satisfactorily assessed, weld metal has proved more of a challenge. The main reason for this is that welding is a very complex process introducing many parameters to the assessment which not have to be considered in studies of base material. For example superduplex weld metal typically solidify fully ferritic but may in case excessive nitrogen is added solidify as a mixture of ferrite and austenite. The solidification mode may vary also between weld passes as a consequence of minor variations in composition. Ferritic solidification is the preferred mode, giving the well known Widmanstätten austenite, which forms in the solid state during cooling. Mixed mode solidification gives a vermicular appearance, which is known to increases the tendency to intermetallic formation. A comprehensive study using computational thermodynamics was done to investigate this matter. This study included equilibrium calculations, Scheil-Gulliver solidification simulations, and calculations of the driving force for intermetallic phase precipitation and further a study of diffusion of Mo and W in these alloy systems. The different approaches were applied on model superduplex weld metals with nominal compositions matching commercial superduplex fillers available today. The principal conclusion is that all thermodynamic calculations clearly indicates the W containing filler to show a more pronounced sensitivity to heat treatments by precipitation of intermetallic phases.

Similar content being viewed by others

References

Hertzman S., Brolund B. and Ferreira P.J.: An experimental and theoretical study of heat-affected zone austenite reformation in three duplex stainless steels, 1997, Met. & Mat. Trans. A, vol. 28, no. 2, pp. 277–285.

Hertzman S., Wessman S., Brorson S. and Liljas M: Wedling of nitrogen alloyed stainless steels — nitrogen balance aspects, 2004, Proc. High Nitrogen steels HNS, Ostend, Belgium, pp. 563–576.

Gregori A. and Nilsson J.-O.: Decomposition of ferrite in commercial superduplex stainless steel weld metals; microstructural transformations above 700 °C, 2002, Met. & Mat. Trans. A, vol. 33, no. 4, pp. 1009–1018.

Nilsson J.-O., Huhtala T., Jonsson P., Karlsson L. and Wilson A.: Structural stability of super duplex stainless weld metals and its dependence on tungsten and copper, 1996, Met. & Mat. Trans. A, vol. 27, no. 8, pp. 2196–2208.

Hertzman S., Huhtala T., Karlsson L., Nilsson J.-O. and Nilsson M., Jargelius-Pettersson R., Wilson A.: Microstructure-property relations of Mo- and W-alloyed super duplex stainless steel weld metals, 1997, Mat. Sci. & Tech., vol. 13, no. 7, pp. 604–613.

Hertzman S., Pettersson R., Frisk K. and Jerwin T.: The relation between alloy composition and kinetics of intermetallic phase formation, Proc. 6th World Duplex Conference, Venice, Italy, 2000, pp. 347–354.

Kondo K., Ueda M., Ogawa K., Okamoto H. and Igarashi M.: Precipitation behaviour of sigma-related phases in 25% chromium based super duplex stainless steels, Proc. Innovation Stainless Steel, Florence, Italy, 1993, vol. 2, pp. 2.191–2.196.

Lee Y.H., Kim K.T., Lee Y.D. and Kim K.Y.: Effects of W substitution on σ and χ phase precipitation and toughness in duplex stainless steels, 1998, Mat. Sci. Tech., vol. 14, no 8, pp. 757–764.

Ahn Y.S. and Kang J.P.: Effect of aging treatments on microstructure and impact properties of tungsten substituted 2205 duplex stainless steel, 2000, Mat. Sci. Tech., vol. 16, no. 4, pp. 382–388.

Okamoto H.: The effect of tungsten and molybdenum on the performance of super duplex stainless steels, 1992, Proc. Applications of Stainless Steel ’92, Stockholm, Sweden, vol. 1 pp. 360–369.

Nilsson J.-O., Wilson A., Josefsson B. and Thorvaldsson T.: Relationship between pitting corrosion, touhness and microstructure for isothermally heat treated super duplex stainless steel, 1992, Proc. Applications of Stainless Steel ’92, Stockholm, Sweden, vol. 1, pp. 280–289.

Nilsson J.-O. and Wilson A.: Influence of isothermal phase transformations on toughness and pitting corrosion of super duplex stainless steel SAF 2507, 1993, Mat. Sci. Tech., vol. 9, no. 7, pp. 545–554.

Nishimoto K., Saida K. and Katsuyama O.: Prediction of sigma phase precipitation in super duplex stainless weldments, Doc. IIW-1717, 2006, Welding in the World, vol. 50, no. 3/4, pp. 13–28.

Lukas H.L., Fries S.G. and Sundman B.: Computational Thermodynamics, the Calphad Method, Cambridge University Press, 2007.

Hillert M.: Calculation of phase equilibria, ASM Seminar on phase transformations 1968, American Society for Metals, pp. 181-218.

Kaufman L. and Bernstein H.: Computer Calculation of Phase Diagrams with Special Reference to Refractory Materials, Academic Press, NY, USA, 1970.

Saunders N. and Midownik A.P.: Calphad Calculations of Phase Diagrams, a Comprehensive Guide, Pergamon Materials Series, vol. 1, 1998.

Fernández Guillermet A.: Thermodynamic calculation of the Fe-Co-W Phase diagram, 1988, Z. Metallkunde, vol. 79, pp. 633–642.

Fernández Guillermet A.: Assessing the thermodynamics of the Fe-Co-Ni system using a CALPHAD predictive technique, 1989, Calphad, vol. 13, pp. 1–22.

Sundman B., Jansson B. and Andersson J.-O.: The Thermo-Calc databank system, 1985, Calphad, vol. 9, no. 2, pp. 153–190.

Scheil E.: Bemerkungen zur Schichtkristallbildung, Retrograde saturation curves, 1942, Z. Metallkunde, vol. 34, pp. 70–72 (in German).

Gulliver G.H.: The quantitative effect of rapid cooling upon the constitution of binary alloys, 1913, J. Inst. Metals, vol.9, pp. 120–153.

Wessman S., Pettersson R., Hertzman S.: On phase equilibria in duplex stainless steels, 2010, Steel Res. Int., vol. 81, no. 5, 337–346.

Andersson J.-O., Höglund L., Jönsson B. and Ågren J.: Fundamentals of Ternary Diffusion, Pergamon Press, NY, USA, 1990.

Hillert M.: Phase Equilibria, Phase Diagrams and Phase Transformations, Their Thermodynamic Basis; Cambridge University Press, (1998)

Thier H., Bäumel A. and Schmidtmann E.: Einfluss von Stickstoff auf das Ausscheidungsverhalten des Stahles X5CrNiMo 1713, Influence of nitrogen on the precipitation behaviour of steel X5CrNiMo 1713, 1969, Arch. Eisenhw., vol. 40, no. 4, pp. 333–339 (in German).

Terada D., Yoshida F., Nakashima H., Abe H. and Kadoya Y.: In-situ Observation of Dislocation Motion and its Mobility in Fe-Mo and Fe-W Solid Solutions at High Temperatures, 2002, ISIJ Int., vol. 42, no. 12, pp. 1546–1552.

Fridberg J., Törndahl L.E. and Hillert M.: Diffsusion in iron, Jernkontorets Annaler, 1969, vol. 153, 263–276.

Nitta H., Yamamoto T., Kanno R., Takasawa K., Iida T., Yamazaki Y., Ogu S. and Iijima Y.: Diffusion of mulybdenum in ?-iron, 2002, Acta Mat., vol. 50, pp. 4117–4125.

Pearson W.B.: A handbook of lattice spacings and structures of metals and alloys, Pergamon Press, 1958.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wessman, S., Karlsson, L., Pettersson, R. et al. Computational Thermodynamics Study Of The Influence Of Tungsten In Superduplex Stainless Weld Metal. Weld World 56, 79–87 (2012). https://doi.org/10.1007/BF03321398

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321398